Why Smart Engineers Rely on Flatform Cables and Lenze Brakes

Industrial machinery relies on specialised components. Two of these components stand out: flatform cables and Lenze brakes.

Industrial machinery relies on specialised components. Two of these components stand out: flatform cables and Lenze brakes.

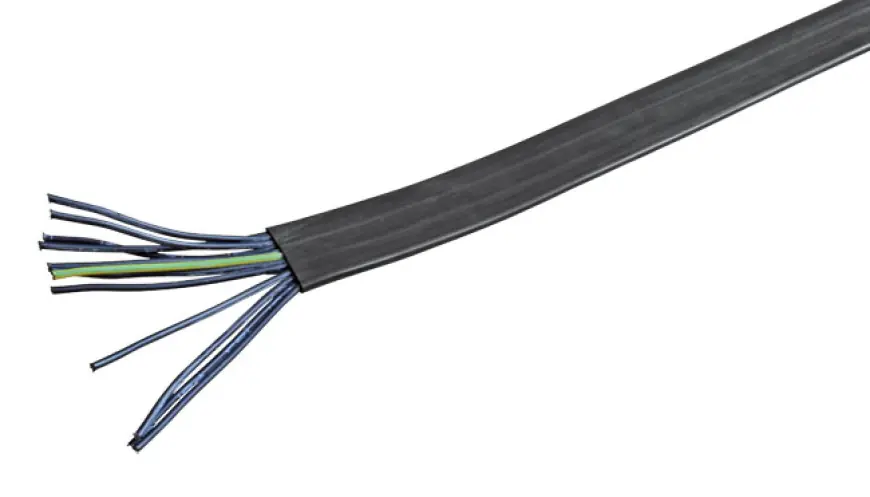

Understanding Flatform Cables

Flatform cables are unique. They’re flat, flexible wiring systems. They’re used in moving machinery like cranes or hoists. Unlike round cables, they’re designed for constant motion. They carry power and signals. They ensure precise control. They’re built to withstand tough industrial settings. Their flat design allows compact installation. This suits tight spaces in crane systems.

The Under-the-Radar Benefits of Flatform Cables

Flatform cables offer more than meets the eye. Their flexibility is a key strength. Cranes move constantly. Standard cables twist or fray. Flatform cables bend without breaking. This reduces downtime. It cuts replacement costs. Their flat shape is another perk. It allows neat cable management. This prevents tangling in cable trays. It simplifies maintenance.

They resist harsh environments. Factories have dust, oil, or extreme temperatures. These cables hold up. They’re insulated against chemical corrosion. They function in heat or cold. This ensures reliability on outdoor sites. Their signal clarity is a hidden gem. Cranes need precise commands. Flatform cables deliver clean signals. This prevents miscommunication during lifts. It boosts safety.

Another advantage is their durability. Constant motion wears out cables. Flatform cables last longer. They reduce the need for frequent replacements. This saves time and money. Their lightweight design is a subtle win. Heavy cables strain systems. These are light yet strong. This eases wear on crane components. It extends equipment life.

Why Operators Value Flatform Cables

Crane operators face high-pressure demands. A cable failure stops work. It delays projects. It frustrates teams. Flatform cables are built for reliability. They’re built for moving systems. They fit specific crane setups. They’re not generic wiring. They handle repetitive motion. Dust or vibration doesn’t faze them. This keeps operations steady.

Their ease of installation is a practical benefit. Replacing cables can be complex. Flatform cables are designed for quick setup. This minimises downtime during repairs. Their compact design fits tight spaces. This allows sleeker crane setups. It gives engineers more design flexibility. Operators appreciate the reduced maintenance. It keeps workflows on track.

Exploring Lenze Brakes

Lenze brakes are electromagnetic systems. They control motion in industrial machinery. They’re used in cranes, conveyors, and automation. They stop or hold loads with precision. They’re not ordinary brakes. They’re engineered for reliability. They operate in demanding conditions. Their design ensures safety and control.

The Hidden Strengths of Lenze Brakes

Lenze brakes have benefits that often go unnoticed. They extend equipment lifespan. Poor brakes stress motors and gears. These brakes are robust. They reduce wear on connected parts. This lowers repair frequency. It saves costs over time. Their fail-safe design is a major plus. They engage without power in emergencies. This is critical for cranes or elevators. It prevents accidents.

Energy efficiency is another advantage. Traditional brakes use more power. Lenze brakes consume less electricity. This reduces operational costs. It supports sustainable practices. Their responsiveness is a quiet strength. They stop instantly when needed. This matters in automation or precision tasks. It ensures accuracy. It cuts downtime.

Their adaptability is a key perk. Industrial systems vary widely. Lenze brakes fit diverse applications. They integrate into cranes or conveyors easily. This simplifies upgrades. Their low maintenance is another benefit. Frequent brake servicing disrupts schedules. These brakes last longer. They need less upkeep. This keeps operations smooth.

Why Engineers Trust Lenze Brakes

Engineers in heavy industries face unique challenges. A brake failure risks safety. It halts production. Lenze brakes are designed for reliability. Heat, dust, or vibration doesn’t stop them. This ensures project timelines stay intact.

Their compact size is a subtle advantage. Modern machinery has limited space. These brakes are small yet powerful. They fit where others can’t. This allows innovative equipment designs. Their quiet operation is another win. Noise disrupts sensitive settings like labs. Lenze brakes minimise sound. This suits precision environments. Their precision control enhances tasks like crane lifts or robotic movements.

How Flatform Cables and Lenze Brakes Work Together

Flatform cables and Lenze brakes complement each other. Cables deliver power and signals. Brakes control motion. Together, they ensure cranes operate smoothly. The cables’ signal clarity supports the brakes’ precision. This creates seamless control. Their durability aligns. Both withstand tough conditions. This reduces maintenance cycles. It boosts overall efficiency.

In crane systems, their synergy shines. Flatform cables power the pendant controls. Lenze brakes stop the crane precisely. This prevents load swings or misplacements. It enhances safety. Their combined reliability keeps operations running. Downtime drops. Projects stay on schedule. This is critical for industrial sites.

Their Role in Industrial Efficiency

Flatform cables and Lenze brakes are more than components. They enable progress. They support safe crane operations. They streamline automation. They ensure precision in heavy industries. They’re tested in real-world scenarios. This confirms their durability. They meet the needs of demanding applications.

Their impact goes beyond function. They reduce operational costs. They enhance equipment longevity. They improve safety standards. For operators, this means fewer interruptions. For engineers, they offer design flexibility. Their combined strengths make industrial systems more reliable. This is vital in construction, manufacturing, or logistics.

Flatform cables and Lenze brakes shine in practical settings. Their combined reliability tackles unique challenges. Cranes on construction sites face constant motion and weather extremes. Flatform cables ensure uninterrupted control signals. Lenze brakes deliver precise stopping power. This prevents load shifts. It enhances worker safety. Their durability reduces unexpected failures. This keeps tight project deadlines intact. Their seamless integration supports complex lifts. It makes them invaluable in high-stakes environments.

Flatform cables and Lenze brakes don’t seek the limelight. They don’t need to. They solve practical problems. They keep cranes moving. They ensure precise stops. They cut maintenance costs. They enhance safety. For those in heavy industries, they’re worth understanding. They’re the quiet forces behind efficient operations. Their benefits lie in the details.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0