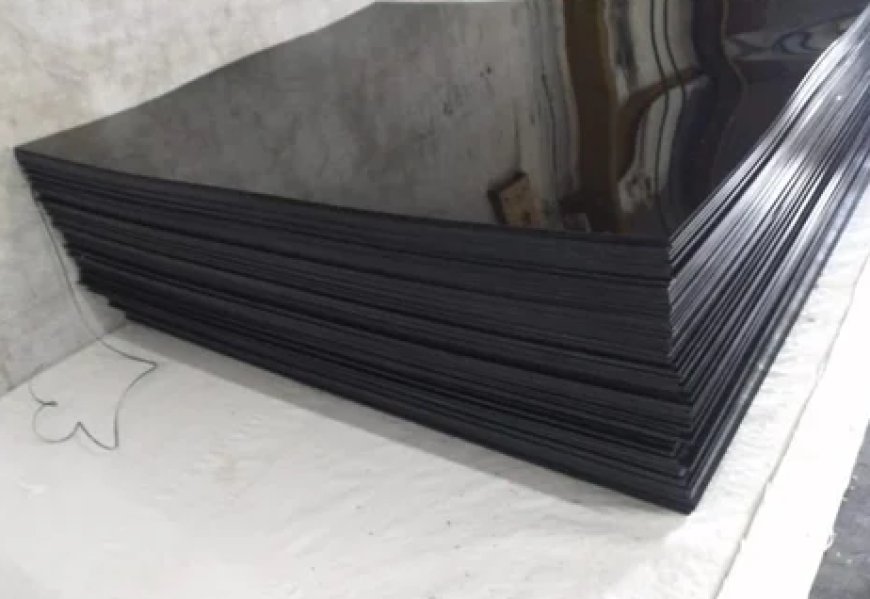

Exploring the Versatility and Benefits of HDPE Sheets

Industrial manufacturing relies on HDPE sheets for their versatility in fabricating components, machine parts, and storage solutions. Their ability to withstand harsh chemicals, abrasion, and mechanical stress makes them indispensable in diverse industrial sectors, including automotive, aerospace, and manufacturing.

High-Density Polyethylene (HDPE) sheets are a versatile material renowned for their durability, flexibility, and wide-ranging applications across various industries. As a leading provider of HDPE sheets, we delve into the many benefits and uses of this robust material that continues to redefine modern engineering and manufacturing.

What are HDPE Sheets?

HDPE sheets are manufactured from high-density polyethylene, a thermoplastic polymer known for its strength and resilience. This material is produced through a process of polymerization of ethylene under high pressure and is characterized by its dense structure and molecular strength. HDPE sheets are available in various thicknesses, sizes, and colors, making them suitable for a multitude of applications.

Advantages of HDPE Sheets

1. Durability and Strength

HDPE sheets are renowned for their exceptional durability and impact resistance. They can withstand harsh environmental conditions, including temperature variations, moisture, and chemicals, making them ideal for both indoor and outdoor applications. Their strength ensures long-term performance and minimal maintenance, reducing replacement costs over time.

2. Chemical Resistance

One of the standout features of HDPE sheets is their resistance to a wide range of chemicals, acids, and solvents. This property makes them suitable for applications in industries such as chemical processing, pharmaceuticals, and food processing where exposure to corrosive substances is common. HDPE sheets maintain their structural integrity and do not degrade when exposed to most chemicals.

3. Lightweight and Easy to Fabricate

Despite their robustness, HDPE sheets are lightweight and easy to handle, making them convenient for installation and transportation. They can be easily cut, welded, and formed into various shapes and sizes without compromising their structural integrity. This versatility allows for customization and adaptation to specific project requirements.

4. Environmental Friendliness

HDPE sheets are considered environmentally friendly due to their recyclability and minimal environmental impact. They are commonly used as a sustainable alternative to materials that are less recyclable or have a higher carbon footprint. HDPE can be recycled into new products at the end of its lifespan, contributing to resource conservation and waste reduction efforts.

5. Versatile Applications

The versatility of HDPE sheets extends across a wide range of industries and applications:

- Construction: Used for protective barriers, wall cladding, and temporary enclosures.

- Manufacturing: Machined into components for machinery, conveyor systems, and equipment housing.

- Agriculture: Utilized in irrigation systems, greenhouse panels, and animal enclosures.

- Packaging: Formed into containers, bins, and pallets for storage and transport.

- Marine: Used for boat components, dock fenders, and marine infrastructure due to its resistance to water and marine organisms.

Why Choose Our HDPE Sheets?

As a trusted supplier of HDPE sheets, we are committed to delivering high-quality products that meet stringent industry standards and exceed customer expectations. Our HDPE sheets are manufactured using advanced techniques and quality control measures to ensure consistency and reliability. Whether you require sheets for industrial applications, construction projects, or specialized manufacturing needs, our expertise and dedication to excellence make us your preferred partner.

Unveiling the Strengths of HDPE Sheets

6. UV Stability and Weather Resistance

HDPE sheets exhibit remarkable resistance to ultraviolet (UV) radiation and weathering, making them ideal for outdoor applications. Unlike many other materials, HDPE maintains its structural integrity and aesthetic appeal even after prolonged exposure to sunlight and extreme weather conditions. This UV stability ensures longevity and reliability in demanding environments.

7. Hygienic and Food-Safe Properties

In industries such as food processing, healthcare, and pharmaceuticals, maintaining hygiene and safety standards is paramount. HDPE sheets are inherently hygienic and FDA-approved for food contact, ensuring they are safe for storing, handling, and transporting food products. Their non-toxic nature and smooth surface prevent bacterial growth and facilitate easy cleaning, making them indispensable in critical hygiene-sensitive applications.

8. Electrical Insulation and Fire Resistance

Electrical insulation is a critical requirement in various electrical and telecommunications applications. HDPE sheets possess excellent dielectric properties, offering superior insulation against electrical conductivity. Additionally, they exhibit high resistance to flames and do not support combustion, making them suitable for use in electrical enclosures, cable insulations, and fire-retardant applications.

9. Impact Resistance and Toughness

HDPE sheets are renowned for their high impact strength and toughness, capable of withstanding heavy impacts without cracking or breaking. This resilience makes them suitable for applications where durability and reliability are essential, such as protective barriers, impact-resistant panels, and vehicle components. HDPE's ability to absorb shock and vibrations ensures enhanced safety and performance in challenging environments.

10. Environmental Sustainability

As global sustainability initiatives gain momentum, HDPE sheets emerge as a sustainable choice due to their recyclability and low environmental impact. They can be recycled into new products at the end of their lifespan, contributing to circular economy principles and reducing reliance on virgin materials. HDPE's eco-friendly profile aligns with corporate sustainability goals and regulatory requirements, making it a preferred material for green building projects and eco-conscious industries.

Applications Across Diverse Industries

11. Construction and Architecture

In the construction sector, HDPE sheets are used for various applications including wall cladding, roofing membranes, and underground piping systems. Their durability, chemical resistance, and ease of installation make them a preferred choice for both residential and commercial building projects.

12. Agriculture and Aquaculture

HDPE sheets play a vital role in agriculture and aquaculture applications, serving as liners for ponds, reservoirs, and irrigation channels. They prevent leakage, minimize water loss, and protect against soil contamination, thereby enhancing water management efficiency and agricultural productivity.

13. Manufacturing and Industrial Processes

Industrial manufacturing relies on HDPE sheets for their versatility in fabricating components, machine parts, and storage solutions. Their ability to withstand harsh chemicals, abrasion, and mechanical stress makes them indispensable in diverse industrial sectors, including automotive, aerospace, and manufacturing.

14. Retail and Display Solutions

In retail environments, HDPE sheets are used for displays, signage, and product shelving due to their lightweight nature, durability, and aesthetic appeal. They offer a cost-effective solution for enhancing product visibility and merchandising efficiency in stores and exhibition spaces.

Conclusion

HDPE sheets represent a pinnacle of modern materials engineering, combining durability, versatility, and environmental responsibility. From industrial machinery to agricultural solutions and beyond, HDPE sheets continue to play a pivotal role in enhancing efficiency, durability, and sustainability across diverse sectors. As technology evolves and applications expand, HDPE remains at the forefront, offering unparalleled performance and reliability.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0