Accelerating Innovation with Quick-Turn Flex Circuits and Rigid-Flex PCB Services

In the competitive landscape of electronics, time-to-market is a crucial factor for success. Engineers and designers are increasingly turning to quick-turn flex circuits and quick-turn rigid-flex PCB services to expedite their product development processes. These advanced technologies not only facilitate rapid prototyping but also ensure high-quality results that meet the demanding standards of various industries.

What Are Quick-Turn Flex Circuits?

Quick-turn flex circuits are flexible printed circuits designed for rapid turnaround times. They allow for intricate designs and layouts that can be easily adapted to fit unique product requirements. This flexibility is particularly beneficial for industries that need to produce prototypes quickly, enabling engineers to test designs and make necessary adjustments without significant delays. By leveraging quick-turn flex circuits, companies can streamline their development cycles and bring innovative products to market faster.

The Advantages of Quick-Turn Rigid-Flex PCB Services

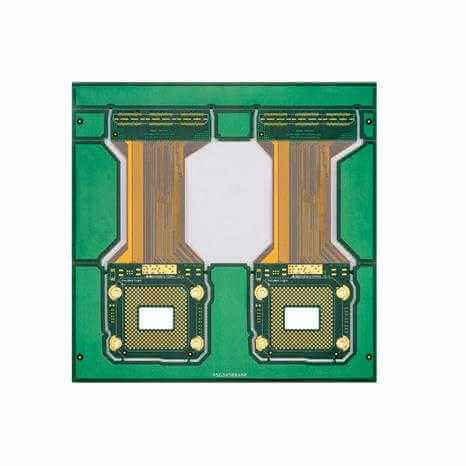

Quick-turn rigid-flex PCB services combine the benefits of both rigid and flexible circuit technologies. These PCBs consist of a combination of rigid and flexible substrates, allowing for enhanced design possibilities and improved performance. Here are some key advantages of utilizing quick-turn rigid-flex PCB services:

- Rapid Prototyping: The ability to quickly produce prototypes means that engineers can iterate on designs efficiently. This is especially important in industries such as aerospace and medical devices, where compliance and performance are critical.

- Space Optimization: Rigid-flex PCBs can be designed to fit complex geometries, maximizing available space in compact devices. This is essential for consumer electronics, where space constraints are often a challenge.

- Enhanced Durability: The combination of rigid and flexible elements provides robustness against mechanical stress and environmental factors, making them suitable for demanding applications in automotive and aerospace sectors.

- Seamless Integration: Quick-turn rigid-flex PCBs are designed for easy integration into existing manufacturing processes, reducing downtime and improving efficiency.

- Cost-Effectiveness: By prioritizing speed without compromising quality, companies can minimize production costs while maximizing output, leading to better ROI.

At the forefront of this technological evolution, our commitment to quality and innovation ensures that you receive top-notch solutions tailored to your specific needs. Whether you require custom design services or fast-turn rigid-flex PCB prototypes, we are here to assist you every step of the way.

As industries continue to evolve and demand more innovative solutions, quick-turn flex circuits and quick-turn rigid-flex PCB services have emerged as vital components in the design and manufacturing processes. By adopting these technologies, businesses can not only accelerate their product development timelines but also enhance overall performance and reliability. If you're ready to take your designs to the next level, consider integrating quick-turn flex circuits and rigid-flex PCB solutions into your workflow. Embrace the future of electronics with speed, efficiency, and superior quality.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0