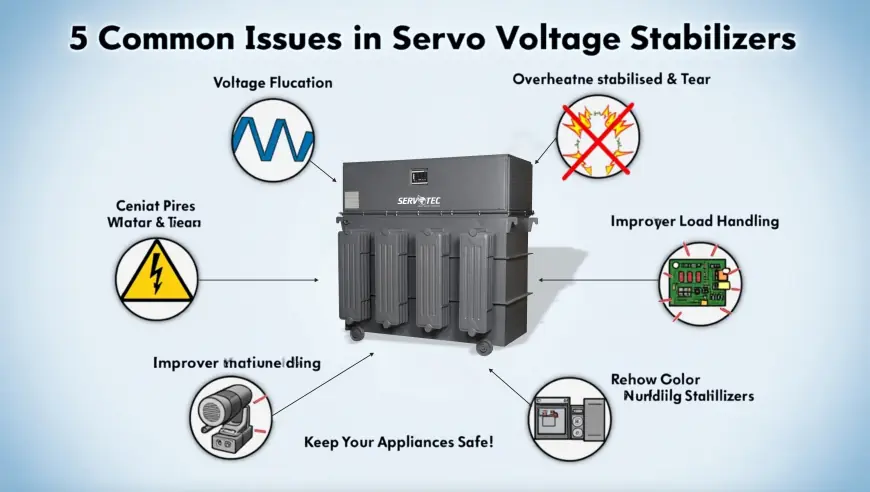

5 Common Issues in Servo Voltage Stabilizers: Keep Your Appliances Safe!

Discover the 5 common issues in servo voltage stabilizers, including voltage fluctuations, overheating, and more. Learn how to fix and prevent these problems for optimal appliance protection. Choose a reliable servo stabilizer company for home or factory use.

Voltage fluctuations are a common headache, especially in regions with inconsistent power supply. That's where a servo voltage stabilizer steps in, ensuring a steady voltage flow to your valuable appliances and machinery. Whether it's a servo stabilizer for home or a robust unit for industrial use, understanding common issues is crucial. Let's dive into the top 5 problems and their solutions.

What is a Servo Voltage Stabilizer?

A servo voltage stabilizer is an electrical device designed to regulate voltage fluctuations. It maintains a constant output voltage, protecting your appliances from damage caused by voltage spikes or drops. These stabilizers are widely used in homes, factories, and industrial setups to ensure the smooth operation of sensitive equipment.

Common Issues in Servo Voltage Stabilizers

-

Voltage Fluctuation Problems:

- Causes: Inconsistent power supply, faulty wiring, or grid instability.

- Impact: Damage to appliances, reduced efficiency, and potential fire hazards.

- Solution: Ensure proper earthing, check wiring regularly, and consider a higher-capacity stabilizer.

-

Overheating:

- Causes: Overload, inadequate ventilation, or prolonged use.

- Impact: Reduced efficiency, component damage, and potential fire risks.

- Preventive Measures: Ensure proper ventilation, avoid overloading, and schedule regular maintenance.

-

Wear and Tear of Servo Motor:

- Causes: Continuous operation, mechanical stress, or lack of lubrication.

- Impact: Inaccurate voltage regulation, slow response time, and eventual failure.

- Solution: Regular servicing, lubrication, and timely replacement of worn-out parts.

-

PCB & Electronic Component Failures:

- Causes: Voltage surges, overheating, or component aging.

- Impact: Malfunction, inaccurate readings, and complete failure of the stabilizer.

- Solution: Use surge protectors, ensure proper cooling, and replace faulty components with genuine parts.

-

Improper Load Handling:

- Causes: Selecting a stabilizer with insufficient capacity for the connected load.

- Impact: Overloading, overheating, and damage to both the stabilizer and connected appliances.

- Solution: Calculate the total load accurately and choose a stabilizer with adequate capacity. Always consult a professional when selecting a servo stabilizer for factory or home use.

How to Fix or Prevent These Issues

- Regular Maintenance and Servicing: Schedule periodic checks by qualified technicians to ensure optimal performance. This includes cleaning, lubrication, and component checks.

- Choosing the Right Servo Stabilizer

- For home use, consider the total load of your appliances. A servo stabilizer for home should be chosen according to the total combined wattage.

- For industrial applications, a servo stabilizer for factory settings needs to handle high power loads and demanding conditions. Consult with a reliable servo stabilizer company for correct sizing.

- Selecting a Reliable Servo Stabilizer Company

- Opt for a reputed servo stabilizer company that offers high-quality products and excellent after-sales service.

- Check for certifications, warranties, and customer reviews before making a purchase.

Conclusion

Servo stabilizers are essential for protecting your valuable appliances and machinery from voltage fluctuations. By understanding the common issues and taking preventive measures, you can ensure the longevity and efficiency of your stabilizer. Always prioritize regular maintenance and choose a reliable servo stabilizer company to guarantee high-quality products and services. Remember, investing in the right servo stabilizer saves you from costly repairs and downtime in the long run.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0