Urbanization Boom Spurs Growth in Precast Concrete Infrastructure

Precast Concrete Market By Product Type (Foundations, Structural Beams, Slabs, Walls, and Other Product Types), By Applications(Structural Building Components, Architectural Building Components, Transportation Products, Waste & Water Handling Products), By End-User(Residential, Non-Residential), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, and Forecast 2023-2032

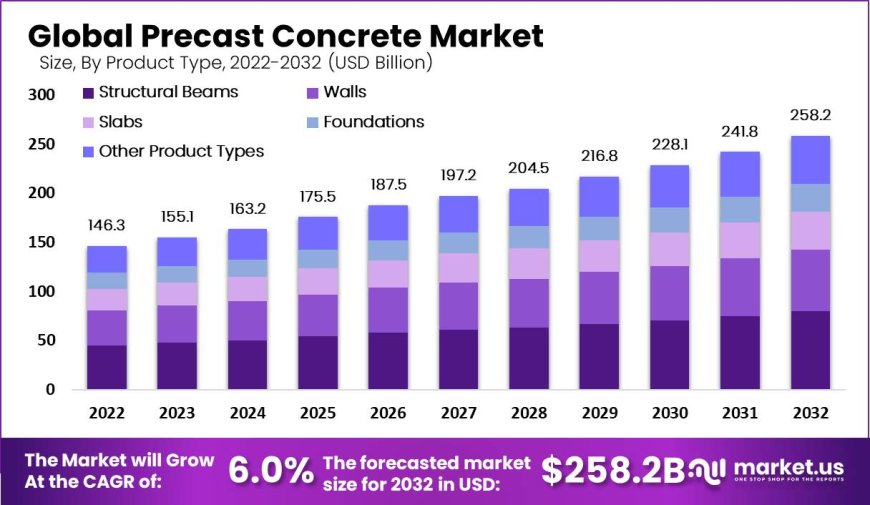

Precast Concrete market size was valued at USD 146.3 Billion and is supposed to reach a valuation of USD 258.2 Billion by 2032. Between 2023 and 2032, this market is estimated to register the highest CAGR of 6.0%.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/precast-concrete-market/#requestSample

Precast concrete refers to concrete elements that are cast in a reusable mold and cured in a controlled environment before being transported to the construction site. This method offers several advantages over traditional onsite casting, including better quality control, enhanced safety, and increased efficiency. The ability to reuse molds multiple times before replacement adds to the cost-effectiveness of precast concrete, making it an attractive option for many construction projects.

The precast concrete market is experiencing significant growth due to the rising trend towards sustainable and cost-effective construction methods. As urbanization and construction activities increase, especially in developing nations, the demand for modern infrastructure is driving the market forward. Precast concrete is not only eco-friendly but also aligns with the industry's shift towards more efficient building techniques.

The growth of this market is expected to continue as more construction projects adopt precast concrete to meet the demands of urban development and infrastructure modernization. This trend highlights the importance of precast concrete in the future of construction, offering a blend of quality, safety, and sustainability.

Market Key Segments

Product Type

-

Foundations

-

Structural Beams

-

Slabs

-

Walls

-

Other Product Types

Application

-

Structural Building Components

-

Architectural Building Components

-

Transportation Products

-

Waste & Water Handling Products

-

Other Applications

End-user

-

Residential

-

Non-Residential

In the precast concrete market, structural beams and building components are experiencing high demand, driven by urbanization and infrastructure development worldwide. Non-residential sectors, such as commercial spaces, educational institutions, and healthcare facilities, dominate the market due to increased public and private investments. Residential segments are also growing, supported by global population growth and government initiatives aimed at affordable housing. This dual growth trajectory underscores the versatility and durability of precast concrete in meeting diverse construction needs across both urban and industrial landscapes.

Market Key Players

-

Boral

-

LafargeHolcim

-

Gulf Precast

-

Olson Precast Company

-

Larsen & Toubro Limited

-

CEMEX

-

Forterra

-

Tindall Corporation

-

Spancrete

-

Elementbau Osthessen GmbH & Co., ELO KG

-

Bouygues Construction

-

Balfour Beatty

-

Oldcastle Precast

-

Other Key Players

Driver:

The advantages of precast concrete, including superior quality, faster construction times, and durability, are major drivers in the market. These benefits attract construction projects seeking efficiency and reliability, particularly in urban and infrastructure developments where time and quality are crucial.

Restraint:

High initial costs and the requirement for skilled labor pose significant challenges to the precast concrete market. The investment in molds and specialized equipment, coupled with the need for trained personnel, limits widespread adoption, especially in developing regions where cost sensitivity is higher.

Opportunity:

The growth of offsite construction, facilitated by precast concrete's suitability for prefabrication, presents a significant opportunity. This method offers advantages like reduced construction time and weather-independent assembly, appealing to industries aiming for faster project completion and enhanced efficiency.

Challenge:

Environmental regulations and sustainability concerns pose challenges to the precast concrete market. Meeting stringent environmental standards while maintaining cost-effectiveness and operational efficiency remains a balancing act for manufacturers and developers alike. Adapting to evolving regulatory landscapes and enhancing sustainable practices will be crucial for long-term growth and market acceptance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0