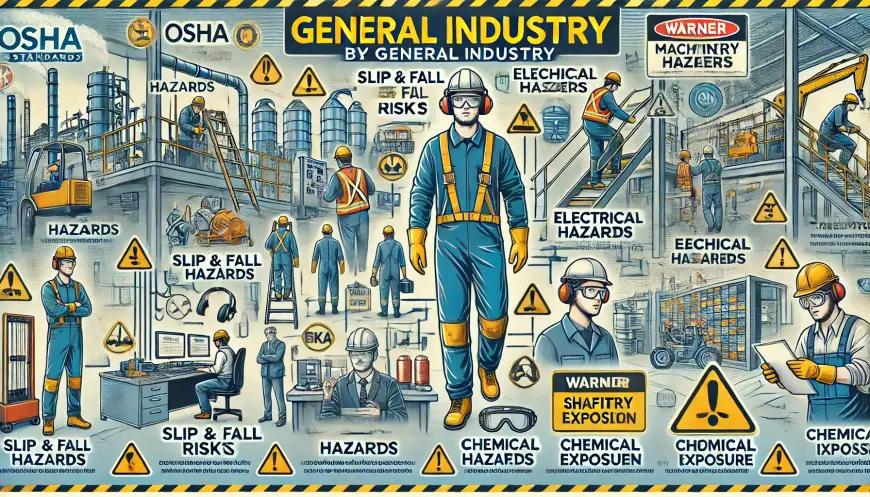

Top OSHA Standards for General Industry Violations and How to Avoid Them

OSHA standards for general industry require businesses to label hazardous substances correctly and provide safety data sheets for all chemicals.

Understanding OSHA Standards for General Industry Violations

Many organizations war to comply with OSHA requirements for popular industry, main to violations that bring about fines and protection risks. These violations often stem from inadequate training, bad place of job situations, or a failure to put into effect protection measures. Understanding the most common violations and a way to prevent them allows businesses hold compliance and protect their personnel.

Employers ought to follow OSHA general enterprise guidelines to reduce place of job risks. By addressing commonplace violations, agencies create safer environments, enhance productiveness, and avoid penalties that may effect operations.

Hazard Communication Violations

One of the most cited violations involves hazard communication. OSHA standards for general industry require businesses to label hazardous substances correctly and provide safety data sheets for all chemicals. Employers must also train employees on how to handle chemicals safely.

To keep away from violations, groups must maintain up to date chance communique applications. Employees have to receive schooling on chemical risks, proper labeling, and emergency techniques in case of exposure. Regular audits make certain that every one required records is offered and updated.

Fall Protection and Walking Surface Violations

Slips, trips, and falls are a main purpose of place of work injuries. Many violations occur because of poorly maintained strolling surfaces, unmarked dangers, or missing guardrails. OSHA trendy enterprise requirements require employers to hold work regions loose from risks and provide fall protection in which essential.

To save you those violations, agencies must look into floors, stairs, and ladders regularly. Proper signage and slip-resistant surfaces help reduce dangers. Employees operating at heights have to use fall safety gadget, and employers ought to provide schooling on its correct use.

Machine Guarding Violations

MACHINE -related injuries often result in missing or insufficient machine guards. OSHA standards for the general industry say that moving parts, such as belts, equipment and knives, should be preserved to prevent emergency contact.

Employers can avoid fractures by ensuring that all machines have proper protection. Employees should receive training in identifying hazards and using equipment safely. Regular maintenance checks help you identify missing or damaged guards before security risk.

Lockout/Tagout Violations

Lockout/tagout approaches save you accidental system startups for the duration of protection. Violations occur while employers fail to put into effect those approaches or whilst personnel are not trained on proper protocols.

Businesses must put into effect clear lockout/tagout packages. Employees need to receive schooling on shutting down and securing system before acting upkeep. Employers have to additionally behavior habitual audits to make sure compliance with OSHA fashionable enterprise policies.

Respiratory Protection Violations

Exposure to risky airborne materials can reason critical health troubles. Many violations arise whilst agencies do no longer offer proper respiration protection or fail to assess workplace air pleasant. OSHA requirements for wellknown enterprise require employers to evaluate breathing risks and supply suitable protective device.

To prevent violations, corporations have to behavior air fine tests and offer employees with respirators desirable to their paintings surroundings. Training on the perfect use, garage, and protection of breathing device is crucial to ensuring compliance.

Electrical Safety Violations

Electrical risks pose huge risks inside the place of job. Violations regularly stem from flawed wiring, exposed electrical parts, or a lack of worker training on electric protection. OSHA widespread enterprise requirements require groups to maintain secure electrical structures and educate people on threat prevention.

Employers can avoid violations by way of making sure electrical panels are well categorised and loose from obstructions. Employees must understand how to handle electric equipment thoroughly. Routine inspections help pick out and accurate capacity hazards earlier than they motive injuries.

Personal Protective Equipment (PPE) Violations

Failure to offer or enforce using private shielding device leads to many OSHA violations. OSHA standards for wellknown enterprise require businesses to assess administrative center hazards and deliver vital PPE, such as gloves, eye safety, and listening to protection.

Employers ought to conduct regular tests to decide appropriate PPE for every job task. Employees must be taught on right PPE use and upkeep. Enforcing PPE rules helps reduce place of business accidents and ensures compliance with protection guidelines.

Fire Safety and Emergency Exit Violations

OSHA requires corporations to have clear emergency exit routes and properly maintained fire protection systems. Violations occur while exits are blocked, fire extinguishers are missing, or personnel are blind to emergency strategies.

To comply with OSHA widespread industry standards, corporations must behavior everyday fireplace drills and ensure all exits remain accessible. Fire extinguishers and alarms ought to be inspected robotically, and employees must gain knowledge of in emergency evacuation techniques.

Conclusion

Avoiding common violations of OSHA standards for general industry requires proactive safety management. Employers must identify workplace hazards, enforce safety protocols, and provide continuous employee training. Compliance with OSHA general industry regulations not only prevents fines but also creates a safer work environment.

By addressing risk conversation, fall protection, gadget guarding, and other vital protection regions, groups lessen the risk of place of job accidents. Regular audits, worker engagement, and adherence to OSHA policies make contributions to a lifestyle of safety. Investing in place of business safety leads to lengthy-term benefits, which includes improved productivity, decrease damage quotes, and stronger worker properly-being.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0