PP Corrugated Sheets: The Lightweight Champion of Versatile Applications

Introduction to PP Corrugated Sheets

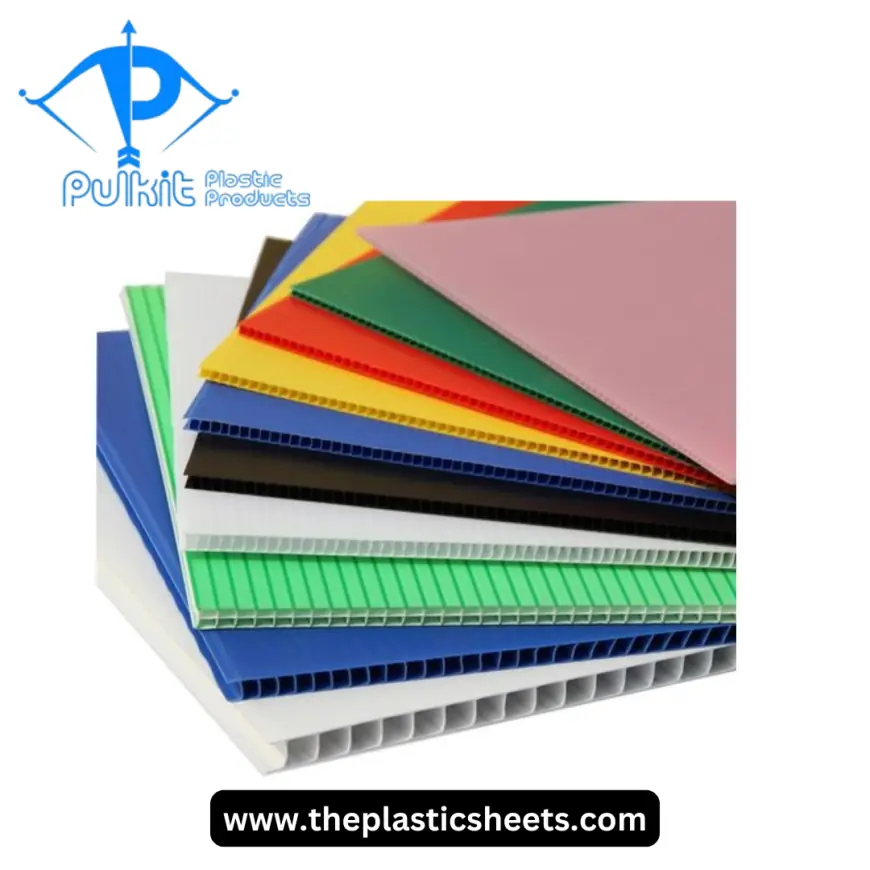

In the world of materials science, innovation continues to drive the development of products that are both functional and sustainable. Among these, PP Corrugated Sheets have emerged as a versatile and lightweight alternative to traditional materials like cardboard, wood, and metal. Made from polypropylene (PP), these sheets boast a unique fluted structure that provides exceptional strength and rigidity while remaining remarkably lightweight. From packaging and signage to construction and agriculture, PP Corrugated Sheets have proven their worth in a wide range of applications. This article delves into the intricacies of PP Corrugated Sheets, exploring their properties, uses, and the factors influencing their price.

Pulkit Plastic Products are essentially twin-wall plastic sheets formed through a process known as extrusion. This results in a series of parallel flutes or channels that run along the length of the sheet, creating a corrugated profile. This design provides significant structural support, allowing the sheets to withstand bending and impact forces, making them ideal for protective and supportive applications. The inherent properties of PP coupled with the corrugated structure contribute to the widespread adoption of these sheets across various industries.

Properties and Characteristics of PP Corrugated Sheets

PP Corrugated Sheets possess a unique combination of properties that make them an attractive choice for various applications. Their lightweight nature makes them easy to handle and transport, reducing labor and shipping costs. Despite their low weight, these sheets exhibit exceptional strength and rigidity due to their corrugated structure. This allows them to withstand heavy loads and resist bending or deformation.

Furthermore, PP Corrugated Sheets are resistant to moisture, chemicals, and UV radiation, making them suitable for both indoor and outdoor use. Unlike cardboard, they won't degrade or warp when exposed to damp conditions. Their durable nature ensures a long service life, reducing the need for frequent replacements. These combined properties contribute to their cost-effectiveness and overall value.

Diverse Applications of PP Corrugated Sheets: From Packaging to Construction

The versatility of Corrugated sheet price is evident in their wide range of applications across various industries. In the packaging sector, they are used for creating durable and reusable boxes, containers, and dividers, providing superior protection for goods during transit. Their moisture resistance makes them ideal for packaging agricultural products, chemicals, and pharmaceuticals.

In the signage industry, PP Corrugated Sheets are used for creating eye-catching and weather-resistant signs, displays, and promotional materials. Their lightweight nature makes them easy to install, while their durability ensures they can withstand outdoor conditions. Additionally, PP Corrugated Sheets are used in construction for temporary flooring protection, formwork, and insulation. Their impact resistance and ease of cutting make them a versatile material for various construction tasks.

In agriculture, these sheets are utilized for creating plant protectors, tree guards, and greenhouse panels. Their ability to withstand moisture and UV radiation protects plants from harsh weather conditions and pests. The sheets can also be used for constructing temporary shelters and animal enclosures.

Factors Influencing Corrugated Sheet Price

Several factors influence the corrugated sheet price, impacting the overall cost-effectiveness of this material. The primary driver is the cost of raw materials, particularly polypropylene resin. Fluctuations in oil prices, which affect the production of PP, directly impact the price of the sheets.

Sheet thickness and density also play a significant role. Thicker and denser sheets require more material and offer greater strength and durability, resulting in a higher price. Manufacturing processes, such as the use of specialized machinery and quality control measures, can also affect the price. Customization options, such as printing, cutting, and coating, can add to the overall cost. Finally, market demand and competition among pp corrugated sheet manufacturers can influence pricing.

Choosing the Right PP Corrugated Sheet Manufacturer

Selecting the right pp corrugated sheet manufacturer is crucial for ensuring quality, reliability, and cost-effectiveness. Look for manufacturers with a proven track record of producing high-quality sheets that meet industry standards. Consider their production capacity and ability to meet your specific requirements, including sheet size, thickness, and customization options.

Evaluate their quality control processes and certifications to ensure they adhere to strict standards. Compare pricing from different manufacturers to find the best value for your budget. Consider their lead times and shipping options to ensure timely delivery. Finally, read customer reviews and testimonials to assess their reputation and customer service.

Advantages Over Traditional Materials

PP Corrugated Sheets offer several advantages over traditional materials like cardboard, wood, and metal. Their lightweight nature makes them easier to handle and transport, reducing labor and shipping costs. Their resistance to moisture and chemicals makes them more durable and suitable for a wider range of applications than cardboard or wood.

Compared to metal, PP corrugated sheet uses are non-corrosive and offer better insulation properties. They are also more cost-effective than metal in many applications. Their versatility and recyclability make them a more sustainable option compared to many traditional materials.

Sustainability and Environmental Considerations

PP Corrugated Sheets offer several environmental benefits compared to traditional materials. They are recyclable and can be repurposed into new products, reducing waste. The manufacturing process is relatively energy-efficient compared to the production of metal or other materials.

Their durability and long service life reduce the need for frequent replacements, minimizing resource consumption. However, it's important to consider the source of the polypropylene resin used in their production. Choosing manufacturers that use recycled PP or sustainable production practices can further reduce the environmental impact.

Future Trends and Innovations

The PP Corrugated Sheet industry is continually evolving with ongoing research and development focused on improving performance and sustainability. Innovations include the use of bio-based polypropylene, which is derived from renewable resources.

Advancements in manufacturing processes are leading to the production of sheets with enhanced strength, durability, and insulation properties. Customization options are becoming more sophisticated, allowing for intricate printing and design possibilities. The growing demand for sustainable materials is expected to drive further innovation and adoption of PP Corrugated Sheets across various industries.

Conclusion: A Versatile Material with a Promising Future

In conclusion, PP corrugated sheet manufacturer have emerged as a versatile and cost-effective material with a wide range of applications. Their unique combination of properties, including lightweight nature, strength, moisture resistance, and recyclability, makes them an attractive alternative to traditional materials. As industries increasingly prioritize sustainability and efficiency, PP Corrugated Sheets are poised to play an even greater role in shaping the future of packaging, signage, construction, and agriculture. Understanding the factors influencing corrugated sheet price and choosing a reputable pp corrugated sheet manufacturer are essential for maximizing the benefits of this versatile material.

Frequently Asked Questions

1. Are PP Corrugated Sheets waterproof?

PP Corrugated Sheets are water-resistant but not entirely waterproof. They can withstand exposure to moisture without degrading, but prolonged submersion may allow some water penetration.

2. How can I cut PP Corrugated Sheets?

PP Corrugated Sheets can be easily cut using a utility knife, saw, or laser cutter, depending on the thickness and complexity of the cut.

3. Are PP Corrugated Sheets recyclable?

Yes, PP Corrugated Sheets are recyclable and can be repurposed into new products. Check with your local recycling facility for specific guidelines.

4. What is the lifespan of PP Corrugated Sheets?

The lifespan of PP Corrugated Sheets depends on the application and environmental conditions. However, they are generally durable and can last for several years with proper care.

pulkitplasticproducts001

pulkitplasticproducts001