Exploring PP Sheets: Properties, Applications, and the Market Landscape

Polypropylene (PP) sheets have gained substantial attention in a diverse array of industries due to their impressive versatility and robust properties. These sheets, crafted from polypropylene resin, exhibit a unique blend of strength, flexibility, and chemical resistance, making them ideal for various applications, from packaging to construction. As organizations increasingly prioritize lightweight and durable materials, the demand for PP sheets continues to rise. This Pulkit Plastic Products delves into the properties, applications, and market dynamics surrounding polypropylene sheets, focusing on pricing, suppliers, and manufacturers.

Understanding Polypropylene Sheets

Polypropylene sheets are produced from a thermoplastic polymer known for its resilience and structural integrity. Due to their unique molecular structure, these sheets possess significant impact resistance, which allows them to endure various environmental factors while maintaining their shape and functionality. Due to their lightweight nature, polypropylene sheets offer a superior strength-to-weight ratio compared to many traditional materials. This quality makes them not only efficient but also a preferred choice in applications requiring minimal weight without sacrificing durability.

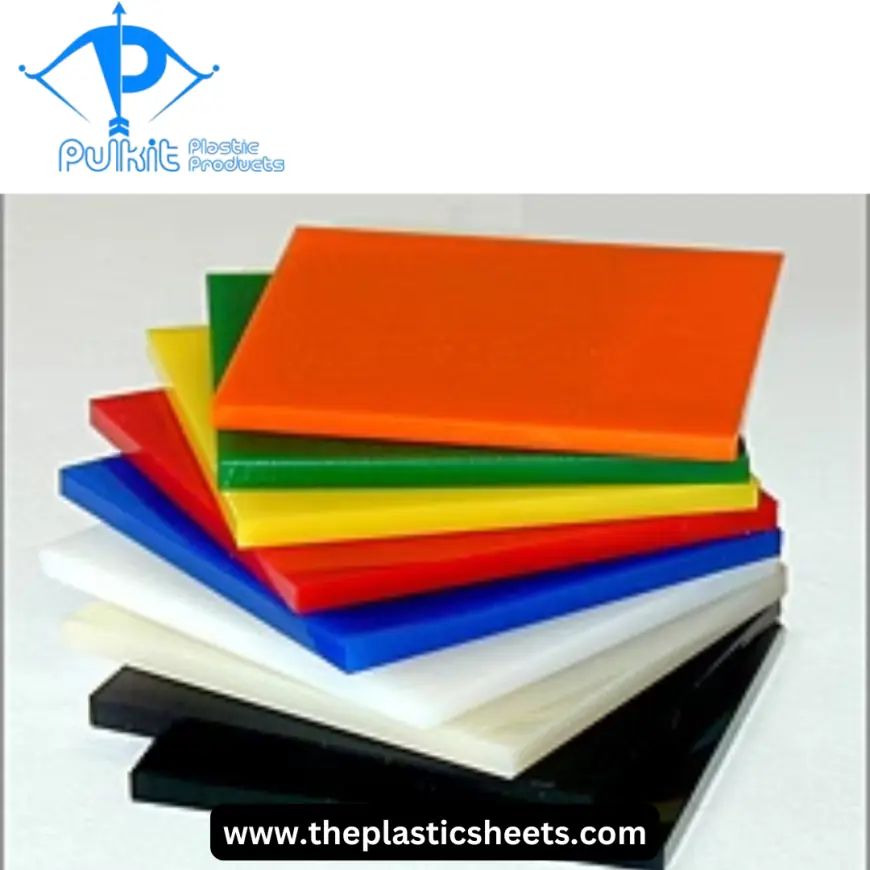

One of the most remarkable characteristics of PP sheets is their excellent chemical resistance, allowing them to withstand exposure to various substances, including acids, bases, and solvents. This resistance is essential for applications in the chemical and pharmaceutical industries, where containers, protective covers, and inter-layer materials must endure harsh conditions without degrading. Additionally, PP sheets are available in various thicknesses, colors, and finishes, providing manufacturers with ample options for customization to meet specific industry demands.

Applications of PP Sheets

The versatility of PP sheet price facilitates their use across multiple sectors. In the packaging industry, PP sheets are commonly employed to create containers, lids, and trays due to their lightweight nature, durability, and moisture-resistant properties. This is crucial for preserving the integrity of food products, ensuring their freshness during transportation and storage. Furthermore, the transparent or colored variants of PP sheets enhance the aesthetic appeal of product packaging, making them visually appealing while offering functionality.

In the construction sector, polypropylene sheets are often utilized as reinforcement materials due to their strength and resistance to environmental factors such as UV radiation and moisture. These properties make them ideal for applications in roofing, insulation, and protective barriers. For example, PP sheets serve as vapor barriers in buildings, preventing moisture infiltration that can lead to mold and structural damage. The resilience of these sheets against heavy loads also makes them suitable for creating lightweight wall panels and flooring solutions.

Moreover, the automotive industry has recognized the potential of PP sheets for interior and exterior components such as dashboards, door panels, and under-hood applications. The lightweight nature of these sheets contributes to overall vehicle efficiency by reducing weight and enhancing fuel economy. As manufacturers aim for more sustainable practices, the recyclability of polypropylene sheets offers an attractive solution for reducing waste in automotive production.

Advantages of Using PP Sheets

Using PP sheets presents numerous advantages that draw manufacturers and consumers alike. One of the primary benefits is their cost-effectiveness. PP sheet prices are generally lower than those of competing materials such as polyvinyl chloride (PVC) or acrylic. This affordability allows companies to maintain quality while optimizing their production costs. The availability of various thicknesses and finishes further enables businesses to select the appropriate type of PP sheet that suits their budget and application needs.

Another significant advantage lies in the ease of fabrication. Polypropylene sheets can be easily cut, fabricated, and welded, making them an ideal choice for custom projects. Manufacturers can create shapes and designs tailored to specific applications, contributing to enhanced product performance and functionality. Additionally, PP sheets can be printed on or laminated, providing further opportunities for customization, branding, and product differentiation.

Furthermore, the chemical resistance and durability of these sheets make them suitable for outdoor and industrial applications. In environments where a material is exposed to harsh chemicals or extreme weather conditions, PP sheets can outlast many alternatives, reducing replacement costs over time. Businesses benefit from longer product lifespans, ultimately leading to improved sustainability efforts by minimizing waste.

Sourcing Polypropylene Sheets: Suppliers and Manufacturers

As the demand for PP sheets grows, so does the number of polypropylene sheets suppliers and manufacturers available in the market. Businesses seeking quality sheets must navigate the landscape of potential suppliers carefully, ensuring they find reliable partners who offer not only high-quality products but also competitive pricing.

When assessing suppliers, it is crucial to consider their reputation and production capabilities. Many established polypropylene sheets manufacturers have extensive experience in the industry and can offer insights into the latest innovations and trends. In looking for a supplier, companies should evaluate lead times, minimum order quantities, and the ability to accommodate custom orders. A trustworthy supplier can facilitate smoother procurement processes and ensure that businesses receive timely and appropriate materials for their projects.

Additionally, engaging with multiple suppliers allows organizations to compare PP sheet prices and availability. By understanding market dynamics, businesses can negotiate better deals, secure cost savings, and ensure they have access to a steady supply of materials that meets their quality standards. Industry trade shows and online platforms are valuable resources for discovering reliable polypropylene sheets manufacturers, allowing businesses to establish connections and partnerships that could benefit their operations.

The Environmental Perspective of PP Sheets

The environmental implications of using Polypropylene sheets suppliers are significant, particularly as sustainability becomes a central focus in many industries. Unlike some thermoplastics, polypropylene is highly recyclable, offering an avenue for reducing plastic waste in the environment. Recycled polypropylene can be repurposed for various applications, including new sheet production, contributing to a circular economy approach that prioritizes resource efficiency.

Many polypropylene sheets manufacturers are increasingly adopting sustainable practices and materials in their operations. Utilizing post-consumer and post-industrial recycled materials not only reduces landfill contributions but also lowers the carbon footprint associated with sheet production. As consumers become more eco-conscious, the demand for sustainable materials continues to rise, pushing manufacturers to innovate and adapt their practices accordingly.

While polypropylene sheets bear an environmental impact during production and disposal, ongoing research into biopolymer alternatives and improved recycling methods holds promise. Growing ventures into biodegradable options aim to create new solutions that mitigate the ecological footprint of traditional PP sheets. By staying updated on advances in sustainable materials, businesses can align their practices with environmental standards while maintaining their competitiveness.

Challenges in the PP Sheet Market

Despite the many advantages of using polypropylene sheets, challenges persist within the market. Fluctuations in raw material prices, driven by changes in fossil fuel costs, can directly influence PP sheet prices. As polypropylene is derived from petroleum, any instability in the oil market can affect production costs and, consequently, pricing for end-users. To mitigate financial risks associated with these fluctuations, businesses must engage in effective supply chain management and explore strategic partnerships with suppliers.

Additionally, the competition among manufacturers and suppliers can lead to market saturation, making it challenging for new entrants to establish themselves. Differentiating products based on quality, customization, or sustainability is vital for attracting and retaining customers in a crowded marketplace. Established manufacturers must continuously innovate and improve their offerings to maintain their competitive edge and address the evolving needs of their clients.

Furthermore, navigating regulatory frameworks surrounding plastic products can pose challenges for companies operating in specific sectors. Environmental regulations may dictate how polypropylene products are produced, recycled, and disposed of, necessitating compliance efforts on the part of manufacturers and suppliers. Keeping abreast of these regulations is essential for businesses looking to remain compliant while pursuing sustainable practices.

Conclusion

The Polypropylene sheets manufacturers have emerged as versatile materials with extensive applications across various industries, driven by their unique properties and advantages. As businesses continue to seek lightweight and durable solutions for packaging, construction, and other sectors, the demand for PP sheets will likely remain robust. By sourcing from reliable polypropylene sheets suppliers and manufacturers, organizations can enjoy access to quality materials that meet their specific needs while navigating challenges such as pricing fluctuations and regulatory landscapes.

As sustainability becomes a critical aspect of business operations, the environmental benefits of polypropylene sheets, alongside ongoing efforts to innovate and improve practices, position them favorably within the packaging and construction sectors. For organizations aiming to harness the full potential of PP sheets, understanding market dynamics, forging strong partnerships, and embracing sustainable practices will be integral to their success in the future.

Frequently Asked Questions

-

What is the average price range for polypropylene sheets?

The price of polypropylene sheets can vary based on thickness, size, and manufacturer. Generally, prices range from $0.50 to $2.50 per square foot, with customized options potentially costing more. -

What industries commonly use PP sheets?

PP sheets are widely utilized in packaging, construction, automotive, electronics, and healthcare industries due to their durability, chemical resistance, and lightweight properties. -

Can polypropylene sheets be recycled?

Yes, polypropylene sheets are recyclable, and many municipalities accept them in recycling programs. Recycled polypropylene can be repurposed for various applications, contributing to sustainability efforts. -

How can I choose a reliable supplier for polypropylene sheets?

When selecting a supplier, consider factors such as their industry reputation, production capabilities, customization options, and commitment to sustainability. Evaluating customer reviews and engaging in discussions with potential partners can aid in making informed decisions.

In summary, understanding the numerous facets of polypropylene sheets empowers businesses to make informed choices that align with operational goals and sustainability commitments.

pulkitplasticproducts001

pulkitplasticproducts001