Digital Printing Gains Traction in Flexible Packaging for Customization and Efficiency

Flexible Packaging Market By Packaging Type (Bags, Pouches, Films and Wraps, Others), By Raw Material (Plastic, Paper, Aluminum, Bioplastics, Polyethylene, Polypropylene, Polyethylene Terephthalate, Others), By Printing Technology (Flexography, Digital Printing, others) By Application (Food & Beverages, Pharmaceutical, Cosmetics, and Other Applications), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2023-2033

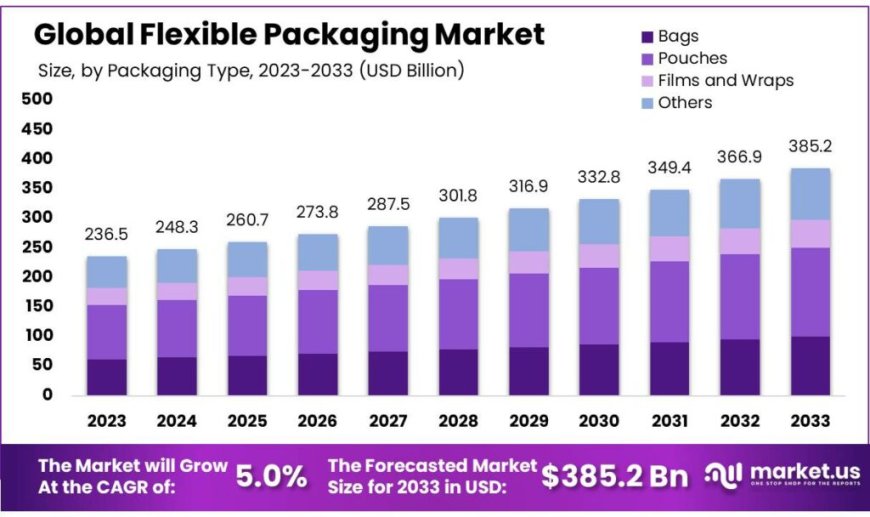

Flexible Packaging Market size is predicted to reach USD 385.2 billion in 2033 and up or down from USD 236.5 billion by 2023 and growing by a CAGR of 5.0% over the period between 2023 and 2033.

The flexible packaging market refers to the industry segment that produces packaging products made from flexible materials, such as plastics, foils, and papers, which can easily change shape. This type of packaging is used extensively across various sectors including food and beverage, pharmaceuticals, cosmetics, and consumer goods, due to its versatility, durability, and cost-effectiveness.

Companies in this sector are increasingly adopting bioplastics, such as bio-based PLA (polylactic acid) film, due to its eco-friendly attributes including recyclability and biodegradability. This shift is aligned with global sustainability goals and consumer preferences for environmentally responsible products.

The flexible packaging market is diverse, with various types of packaging serving distinct needs. In 2023, pouches led the market with a 39.2% share due to their versatility and convenience features like zippers and spouts. Bags followed with a 31.5% share, valued for their flexibility in storing various items.

Flexible packaging materials are dominated by plastics, which accounted for 64.9% of the revenue in 2023 due to their low cost and widespread use in food and beverage industries.

Download a sample report in MINUTES@ https://market.us/report/flexible-packaging-market/request-sample/

Маrkеt Ѕеgmеntѕ

By Packaging Type

-

Bags

-

Pouches

-

Films and Wraps

-

Others

By Raw Material

-

Plastic

-

Paper

-

Bioplastics

-

Polyethylene

-

Polypropylene

-

Polyethylene Terephthalate

-

Others

By Printing Technology

-

Flexography

-

Digital Printing

-

Others

By Application

-

Food & Beverages

-

Pharmaceutical

-

Cosmetics

-

Other Applications

Маrkеt Кеу Рlауеrѕ

-

Amcor plc

-

Mondi Group

-

Berry Global Inc

-

Huhtamaki Flexible Packaging

-

Sonoco Products Company

-

SEE (Sealed Air Corporation)

-

Constantia Flexibles

-

ProAmpac

-

Transcontinental Inc.

-

Graphic Packaging International, LLC

-

Bemis Manufacturing Company

-

Novolex

-

Wipak Group

-

DS Smith

-

Sigma Plastics Group

-

Other Key Players

Driver:

Lightweight and made from inexpensive materials, flexible plastic packaging reduces manufacturing, transportation, and storage costs, making it a preferred choice for many industries. Additionally, its barrier films protect products from moisture, air, and contaminants, significantly prolonging the shelf life of perishable items like food and beverages, ensuring they remain fresh and safe for extended periods.

Restraint:

The high cost of raw materials and inadequate recycling infrastructure are significant restraints for the flexible plastic packaging industry. Fluctuating prices of key materials like polyethylene and polypropylene increase production costs. Furthermore, limited recycling capabilities lead to environmental pollution, as many regions lack the advanced infrastructure needed for efficient recycling, resulting in plastic waste accumulation in landfills and natural habitats.

Opportunity:

There is a growing opportunity for flexible plastic packaging manufacturers to implement sustainable packaging solutions. Consumers are increasingly favoring brands that prioritize environmental responsibility. Companies are investing in research for eco-friendly materials, launching recycling initiatives, and designing easily recyclable packaging.

Challenge:

The recyclability of flexible plastic packaging is a significant challenge due to its complexity. Multi-layer packaging, which includes various polymers and inks, is particularly difficult to sort and recycle. Polypropylene (PP) films, with their lower melting point, can cause problems by sticking to recycling machinery and causing disruptions. This issue complicates the recycling process, especially when PP films are mixed with other plastics, posing a challenge for the packaging industry in achieving effective recycling.