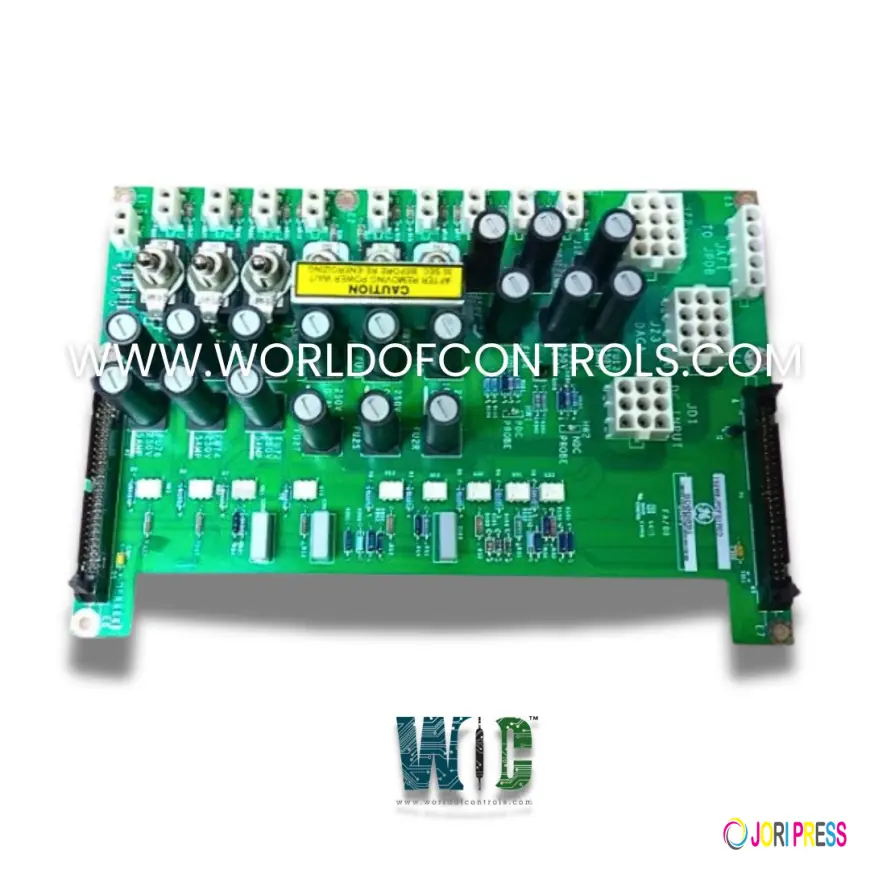

Critical Power Infrastructure in GE Mark VIe Control Systems

Learn why stable DC power is vital to GE Mark VIe control systems in turbine operations and how it ensures uptime and protection

Introduction

In modern power generation and industrial environments, turbine control systems demand precision, reliability, and uninterrupted performance. Among the most widely used platforms in the turbine industry is the GE Mark VIe Control System—a sophisticated, high-performance solution designed for gas, steam, and hydro turbines.

While much of the attention often goes to processors, I/O modules, and communication interfaces, an equally critical yet understated component is the DC power distribution infrastructure. These modules form the backbone of the control system by supplying stable and protected power to every critical subsystem.

The Role of Power Infrastructure in Control Systems

Control systems like the Mark VIe rely on a stable DC power source to function correctly. Without reliable power delivery, key operations such as data acquisition, actuator control, safety logic, and communication can falter—potentially leading to process disruptions or equipment damage.

DC power distribution modules serve several essential functions:

-

Routing power to various parts of the control cabinet

-

Isolating power channels to protect against faults

-

Distributing voltage across I/O packs and controllers

-

Monitoring and indicating the health of power supply lines

-

Providing fuse protection against overcurrent and short circuits

These modules are designed to maintain operational continuity, even under abnormal power conditions, ensuring that the turbine control system remains functional when it matters most.

Understanding DC Power Distribution in the Mark VIe

In a typical GE Mark VIe control panel, the DC power distribution module acts as a central hub for organizing and managing the flow of low-voltage power. Whether operating on 24VDC or 125VDC, this module takes input from redundant power sources and channels it to downstream components like I/O modules, processors, terminal boards, and communication cards.

Key Features and Capabilities:

-

Multiple fused outputs: Each output line is independently protected to isolate faults without affecting the entire system.

-

Status indicators: LEDs provide quick visual feedback for power status and fuse health.

-

Diagnostic integration: Power status can often be monitored remotely through the system’s software interface.

-

Ease of replacement: Modular design allows for rapid swap-out in case of failure, minimizing downtime.

This module doesn’t just deliver power—it safeguards it, organizes it, and communicates its status to operators and maintenance personnel.

Applications in Turbine Control

In turbine systems, precise power management is critical during operations like:

-

Startup and shutdown sequencing

-

Fuel control and valve actuation

-

Real-time sensor monitoring

-

Safety trips and emergency shutdowns

The power distribution module ensures that each of these operations has the electrical foundation it requires. In gas turbines, for instance, control system failure during startup can cause costly delays or even mechanical stress. By maintaining clean, uninterrupted power to all control elements, the module supports seamless transitions and operational reliability.

Enhancing Reliability and Safety

Unreliable power infrastructure can compromise not only system performance but also plant safety. In response, the Mark VIe’s DC power distribution design emphasizes:

-

Redundancy: Often supplied by dual battery-backed sources for failover protection

-

Segregation: Isolating different voltage levels or functional zones

-

Fault tolerance: Quick identification and isolation of issues via fuses and diagnostics

In high-stakes industrial environments, these features enable operators to detect and respond to electrical issues before they escalate into failures.

Conclusion

The power distribution module may be one of the less visible components in a GE Mark VIe control system, but its role is vital. By organizing and protecting the flow of DC power, it ensures the reliable operation of every subsystem—from critical safety interlocks to precision control loops.

In an industry where uptime, safety, and performance are paramount, robust power infrastructure isn’t optional—it’s essential. Whether during startup, normal operation, or emergency shutdown, the integrity of the DC power system determines the reliability of the entire control architecture.

Investing in well-engineered power distribution within turbine control systems is a strategic move toward safer, smarter, and more efficient plant operations.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0