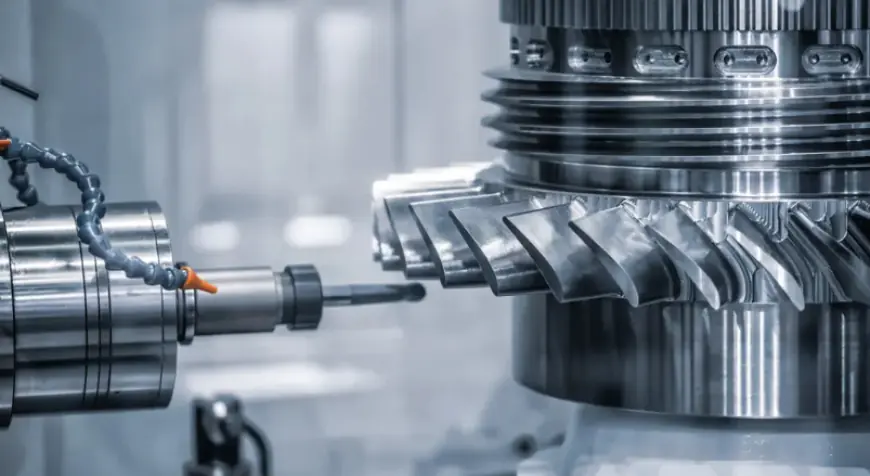

CNC Milling Services: Precision Engineering at Its Best

In the modern world of manufacturing, precision and efficiency are the keys to staying ahead of the competition. With industries demanding more complex and intricate parts at faster rates, the need for advanced machining technologies has never been greater. Enter CNC (Computer Numerical Control) milling – a revolutionary technology that has transformed the way parts and components are manufactured. In this article, we will delve into the world of CNC milling services, how they work, and why they are essential for businesses that require precision-engineered parts.

What is CNC Milling?

CNC milling is a computer-controlled machining process that uses a rotating cutting tool to remove material from a workpiece to create a desired shape or design. Unlike traditional milling, which requires manual operation by a machinist, CNC milling relies on pre-programmed computer software to control the movement of the machine. This automation allows for greater precision, repeatability, and speed in producing parts with intricate designs.

The CNC milling process is often used to create parts from a wide range of materials, including metals, plastics, and composites. The key advantage of CNC milling is its ability to produce highly accurate parts with tight tolerances, making it a critical technology in industries like aerospace, automotive, medical devices, and electronics.

Types of CNC Milling Machines

CNC milling machines come in various types, each suited for different applications. Some of the most common types include:

-

Vertical Milling Machines

These machines have a vertically oriented spindle that allows the cutting tool to move up and down. Vertical mills are ideal for creating parts with flat surfaces, pockets, and other features that are easy to machine from the top. They are commonly used in industries like manufacturing, prototyping, and tooling. -

Horizontal Milling Machines

Horizontal mills have a horizontally oriented spindle, which provides greater stability and power for heavy-duty milling operations. These machines are well-suited for cutting large, thick materials and are typically used in high-volume production runs. -

5-Axis CNC Milling Machines

5-axis machines offer more flexibility than their 3-axis counterparts by allowing movement along five different axes (X, Y, Z, A, and B). This makes them ideal for creating complex, multi-dimensional parts and is particularly useful in aerospace and medical industries. -

CNC Routers

CNC routers are specialized machines designed for cutting and shaping materials like wood, plastics, and soft metals. They are often used for woodworking, sign-making, and prototyping but can also handle small-scale metalworking projects. -

CNC Swiss Machines

These are high-precision machines designed for turning small, intricate parts with tight tolerances. They are often used in industries like medical devices, electronics, and watchmaking.

Each of these machines has its own unique advantages and applications, making CNC milling an extremely versatile process capable of meeting the diverse needs of various industries.

The CNC Milling Process Explained

The CNC milling process involves several stages, each crucial for ensuring the quality and precision of the final product:

-

Designing the Part

The first step in the CNC milling process is to create a design for the part using computer-aided design (CAD) software. This design is then converted into a machine-readable format (G-code) through computer-aided manufacturing (CAM) software. The G-code contains instructions for the CNC machine, guiding it on how to move the cutting tool and the workpiece. -

Preparing the Machine

Once the design and G-code are ready, the CNC machine is set up. The workpiece is securely clamped onto the machine’s worktable, and the appropriate cutting tool is installed. The machine’s settings, such as feed rates, spindle speed, and cutting depth, are adjusted to suit the material and design. -

Cutting the Part

With the machine set up and the program running, the CNC milling machine begins the process of material removal. The cutting tool rotates at high speeds, and the machine’s movements are guided by the G-code to gradually shape the material into the desired form. Depending on the complexity of the part, multiple passes with different cutting tools may be required to achieve the final result. -

Finishing Touches

Once the rough cutting is done, the part undergoes finishing operations, such as deburring, polishing, or coating, to enhance its appearance and performance. These steps are crucial for ensuring that the part meets the required specifications and quality standards. -

Inspection and Quality Control

After the part is machined, it undergoes rigorous inspection to ensure it meets the required tolerances and specifications. This step often involves measuring the dimensions of the part using tools like micrometers, calipers, and coordinate measuring machines (CMMs). Any deviations from the design are corrected before the part is approved for use.

Why Choose CNC Milling Services?

CNC milling services offer a range of benefits that make them an essential choice for manufacturers and businesses looking to produce high-quality, precise parts. Some of the key advantages include:

-

Precision and Accuracy

One of the primary benefits of CNC milling is its ability to produce parts with extremely tight tolerances. Computer-controlled machines can make fine adjustments with precision, resulting in parts that are almost identical, even in large production runs. -

Complex Geometries

CNC milling is capable of producing parts with intricate geometries, making it ideal for industries that require complex, high-performance components. Whether it's a part with multiple curves, angles, or holes, CNC milling can handle it all. -

Reduced Lead Times

With the automation of the CNC milling process, manufacturers can significantly reduce the time it takes to produce parts. This makes it an excellent option for companies that need to meet tight deadlines and keep production schedules on track. -

Material Versatility

CNC milling can handle a wide range of materials, from metals like aluminum, steel, and titanium to plastics and composites. This versatility makes it an attractive option for industries with diverse material requirements. -

Scalability

Whether you need a one-off prototype or a high-volume production run, CNC milling services can scale to meet your needs. With the ability to quickly adjust settings and change cutting tools, CNC milling is perfect for both small-batch and mass production. -

Cost-Effective for High-Volume Runs

While CNC milling services can have a higher initial setup cost, the efficiency and accuracy it provides make it a cost-effective choice for large-scale production. The ability to produce consistent parts with minimal waste results in cost savings over time.

Applications of CNC Milling Services

CNC milling services have a wide range of applications across various industries. Some of the most common include:

- Aerospace: CNC milling is used to create lightweight, high-strength components like turbine blades, aircraft wings, and structural frames.

- Automotive: Automotive manufacturers rely on CNC milling to produce precision engine parts, transmission components, and custom parts for both production cars and racing vehicles.

- Medical Devices: CNC milling is used in the medical industry to produce parts for implants, prosthetics, and surgical instruments, requiring high precision and biocompatible materials.

- Electronics: CNC milling is often employed to create intricate electronic housings, connectors, and circuit board components.

- Industrial Equipment: From custom machinery parts to heavy-duty industrial components, CNC milling is essential in manufacturing equipment that meets strict performance standards.

Conclusion

CNC milling services are an indispensable part of modern manufacturing, providing unmatched precision, versatility, and efficiency in the production of complex parts. Whether you're in aerospace, automotive, medical devices, or any other industry, CNC milling can help you meet your production needs with consistency and accuracy. As technology continues to advance, the capabilities of CNC milling will only expand, making it an even more valuable tool for engineers and manufacturers worldwide.

By choosing CNC milling services, businesses can stay ahead of the competition, offering high-quality products and reducing time to market, all while ensuring precision and cost-effectiveness.