Why Investing in a Laser Engraving Machine is a Smart Choice for Modern Businesses

This article explores the benefits of laser engraving technology, its applications, and why choosing the right machine can be a game-changer for businesses.

As industries continue to evolve, the demand for precision, efficiency, and cost-effective production methods has never been greater. A laser engraving machine is an essential tool for businesses seeking high-quality, permanent markings on a variety of materials. Whether you're in manufacturing, customization, or industrial production, investing in a laser engraving machine offers numerous advantages, from increased productivity to enhanced product durability.

This article explores the benefits of laser engraving technology, its applications, and why choosing the right machine can be a game-changer for businesses.

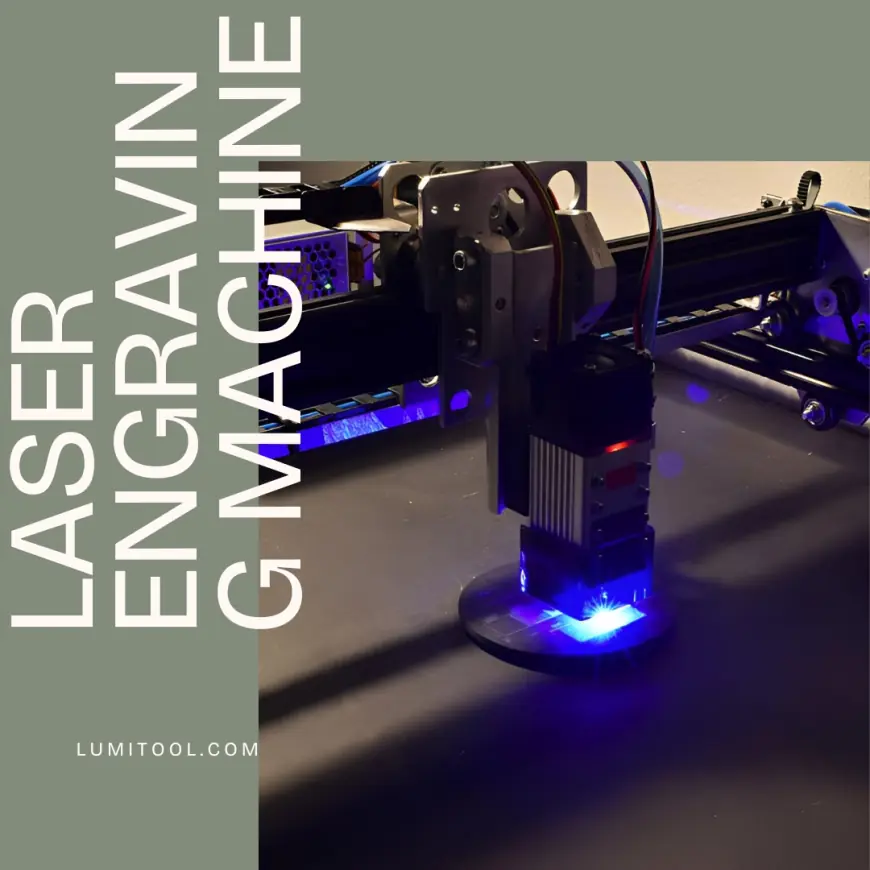

What is a Laser Engraving Machine?

A laser engraving machine uses a concentrated laser beam to etch or engrave designs, text, or barcodes onto different surfaces with incredible precision. Unlike traditional engraving techniques, laser engraving is a non-contact process, eliminating wear and tear on tools while ensuring high-quality, permanent results.

Key Benefits of Investing in a Laser Engraving Machine

1. Unmatched Precision and Quality

- Laser engraving produces fine details, ensuring clear and sharp markings.

- High-resolution engravings make it perfect for intricate designs, logos, and text.

- Delivers consistent results across multiple production cycles.

2. Durability and Permanence

- Engravings are resistant to fading, corrosion, and environmental damage.

- Ideal for industries requiring permanent product identification, such as medical and aerospace sectors.

- Ensures compliance with industry regulations by providing long-lasting markings.

3. Cost-Effective and Low Maintenance

- No need for ink, chemicals, or physical engraving tools, reducing operational costs.

- Minimal maintenance due to the non-contact engraving process.

- Higher return on investment (ROI) as the machine requires fewer consumables.

4. Fast and Efficient Production

- High-speed engraving improves workflow and increases production output.

- Can handle bulk engraving without compromising accuracy.

- Reduces production time compared to traditional methods.

5. Eco-Friendly Technology

- No hazardous chemicals or waste materials are involved in the process.

- Energy-efficient operation minimizes environmental impact.

- Helps businesses comply with sustainability regulations.

Applications of Laser Engraving Machines

1. Industrial Manufacturing

- Engraving serial numbers, part numbers, and barcodes for traceability.

- Marking tools and machinery components with durable identification codes.

- Enhancing quality control with permanent product branding.

2. Electronics and Semiconductor Industry

- Marking circuit boards, chips, and small electronic parts with precision.

- Engraving anti-counterfeiting codes on high-tech components.

- Ensuring traceability and authenticity of electronic products.

3. Medical and Pharmaceutical Industry

- Engraving batch numbers and expiration dates on pharmaceutical packaging.

- Permanent markings on surgical instruments for identification.

- Ensuring regulatory compliance in medical device manufacturing.

4. Jewelry and Luxury Goods Customization

- Engraving intricate designs on rings, bracelets, and watches.

- Adding personalization to gifts and high-end accessories.

- Creating authenticity markings for luxury brands.

5. Automotive and Aerospace Industry

- VIN (Vehicle Identification Number) engraving for security and compliance.

- Marking aircraft components with part numbers and safety instructions.

- High-contrast engraving on metal and alloy surfaces.

Why Choose Lumitool’s Laser Engraving Machines?

Lumitool offers cutting-edge laser engraving machines designed for businesses that require superior quality, efficiency, and durability. Here’s why Lumitool stands out:

- Advanced Laser Technology: High-speed and precise engraving for various applications.

- User-Friendly Software: Intuitive controls for easy customization and automation.

- Long-Lasting Performance: Industrial-grade machines built for continuous operation.

- Customizable Solutions: Tailored engraving options to meet specific industry needs.

Conclusion

Investing in a laser engraving machine is a smart decision for businesses looking to enhance their production process, improve product quality, and reduce operational costs. With the ability to engrave on a wide range of materials and applications across multiple industries, laser engraving technology is a long-term asset that provides high efficiency and sustainability.

Lumitool’s laser engraving machines deliver industry-leading performance, helping businesses achieve precise, durable, and cost-effective engraving solutions. Whether you're in manufacturing, customization, or high-volume production, Lumitool has the right engraving machine to meet your needs.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0