Unraveling the Strength and Versatility of PP Woven Bags: A Comprehensive Guide

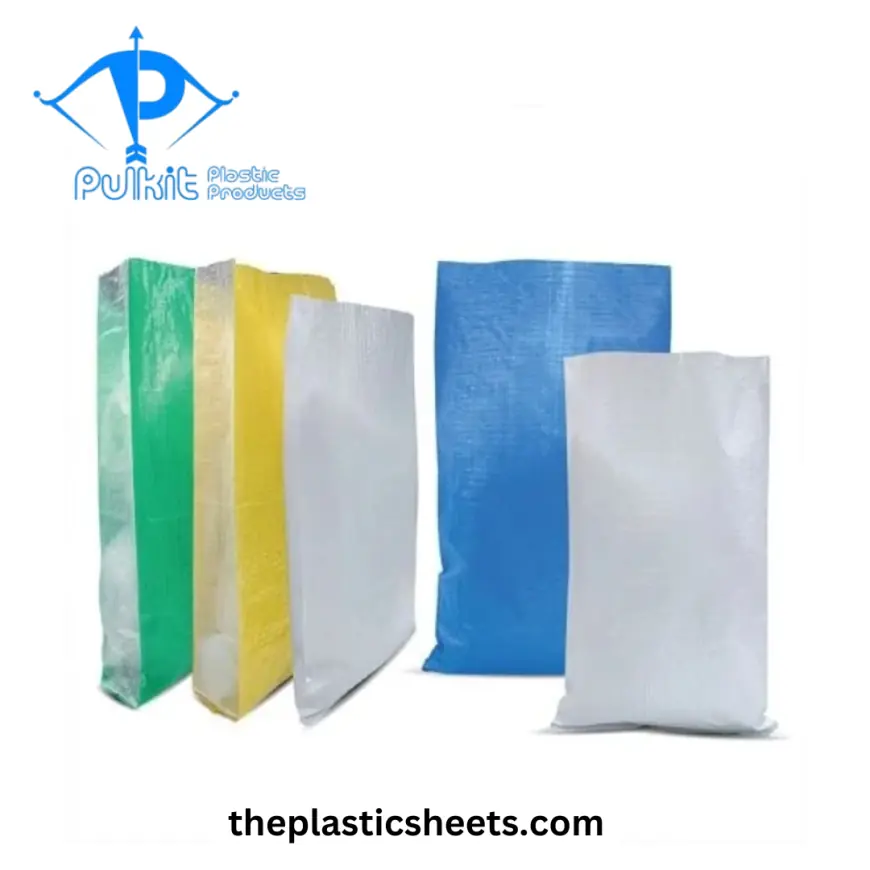

PP woven bags, also known as polypropylene woven bags, represent an indispensable packaging solution in a multitude of industries, providing strength, durability, and cost-effectiveness. Crafted from interwoven polypropylene (PP) strips, these bags offer exceptional tensile strength and resistance to tearing, making them ideal for handling and transporting a wide array of products, from grains and fertilizers to chemicals and construction materials. This comprehensive exploration delves into the core aspects of PP woven bags, covering their manufacturing process, diverse applications, market trends, and key players, including the role of pp woven bag manufacturers and the factors influencing the PP Woven Bag price. We will explore the visual landscape through Pulkit Plastic Products images and give readers a deep understanding of the value of this staple in the industry.

The manufacturing of PP woven bags is a highly automated and precise process, ensuring consistency in quality and performance. The process begins with the extrusion of polypropylene resin into thin, flat tapes or strips. These strips, often referred to as "yarns", are then stretched and oriented to increase their tensile strength. These yarns are then wound onto bobbins, which feed them into circular or flat weaving looms. The weaving process interlocks the PP yarns, creating a robust and resilient fabric. The woven fabric is then rolled up for further processing, including cutting, printing, and stitching. Printing is done to display product information, branding, and other essential details on the bags, providing an avenue for brand recognition and traceability. Finally, the bags are cut to the desired size, and then stitched or sealed, depending on the intended use. The strength of the weave, the thickness of the yarns, and the overall bag design influence the load-bearing capacity, making it adaptable to different requirements. The careful management of each stage of the process ensures that the pp woven bag manufacturers produce bags that meet the highest standards.

Applications Across Industries: A Spectrum of Possibilities

The versatility of PP woven bags makes them the packaging solution of choice across diverse industries. In agriculture, they are extensively used for packaging grains, seeds, animal feed, and fertilizers. The bags' resistance to moisture and tearing protects the contents from damage during storage and transportation, ensuring product integrity and reducing losses. The construction industry relies heavily on PP woven bags for packaging cement, sand, gravel, and other building materials. Their durability enables them to withstand rough handling, and they protect against damage from moisture and abrasion. Chemical and fertilizer manufacturers utilize these bags for packaging a wide range of products, including powdered and granular chemicals. Their chemical resistance prevents reactions between the bag and the contents, ensuring product safety and quality. The food industry also utilizes these bags for packaging products like rice, sugar, and flour. These bags are designed to comply with food safety regulations and provide a sanitary packaging solution. Even in the retail industry, PP woven bags are found as shopping bags and reusable tote bags, providing an eco-friendly alternative to single-use plastic bags.

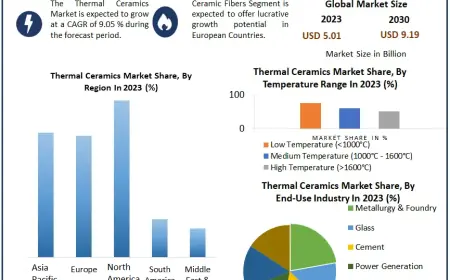

Understanding the Market: Trends, Demand, and Pricing Dynamics

The market for PP woven bag manufacturers is characterized by steady growth, driven by factors such as the increasing global population, growing industrialization, and the rising demand for durable and cost-effective packaging solutions. The market is also influenced by factors such as government regulations and the preference for sustainable packaging alternatives. The demand for PP woven bags is particularly strong in developing countries, where the agricultural and construction sectors are expanding rapidly. The market is also influenced by technological advancements in bag design, printing, and manufacturing processes. PP Woven Bag price is an important factor, which is affected by a range of factors, including the cost of raw materials (polypropylene resin), manufacturing costs, bag size and thickness, printing requirements, and the order volume. Competition among pp woven bag manufacturers can lead to fluctuations in price, which can impact purchasing decisions. The price can also vary depending on the geographic location of the manufacturer and the distribution network.

Features and Benefits: Advantages of PP Woven Bags

PP woven bags offer a compelling set of benefits that make them the preferred packaging choice for many businesses. Their high tensile strength makes them capable of withstanding significant loads, minimizing the risk of tearing or bursting during handling and transportation. PP woven bags are resistant to moisture, preventing product spoilage and maintaining product quality, a critical factor in the storage and shipping of food items. These bags are also resistant to chemicals, which is essential when dealing with chemicals or fertilizers. PP woven bags are lighter than many alternative packaging options, reducing shipping costs and minimizing environmental impact. The bags are cost-effective compared to other packaging solutions, which further increases their appeal. PP woven bags are also recyclable and can be reused for multiple purposes, reducing waste and promoting environmental sustainability. The customization options are also a plus: the bags can be printed with custom designs, branding, and product information. This contributes to improved brand recognition and consumer trust.

Exploring Design Variations: Bag Types and Customization

The PP Woven Bag price are available in various designs and configurations to meet the specific requirements of different products and applications. The most common type is the open-mouth bag, which is filled from the top and then stitched or sealed. These are suitable for products that are poured or manually loaded. Valve bags have a pre-formed valve that allows for easy filling using automated filling equipment. These are commonly used for fine powders and granular materials. The gusseted bags have side gussets that expand to increase the bag's capacity and allow for better stacking. These are often used for bulky products. The printed bags have custom graphics, branding, and product information printed on the surface, allowing for brand recognition and consumer engagement. Bags can also be laminated with a film layer for enhanced moisture resistance and printing quality. Other customizations include UV stabilization for outdoor applications, vent holes for air circulation, and handles for easy carrying. The specific design of the bag will be determined based on the type of material to be packed.

Finding the Right Manufacturer: Key Considerations

Selecting the right pp woven bag manufacturer is a crucial decision that can have a significant impact on the cost, quality, and timely delivery of your packaging needs. Consider several factors:

- Quality: Ensure the manufacturer adheres to strict quality control processes and produces bags that meet industry standards and your specific requirements.

- Experience: Opt for a manufacturer with extensive experience in producing PP woven bags, as they will have the expertise to address your specific needs.

- Capacity: Make sure the manufacturer has sufficient production capacity to handle your order volume and meet your deadlines.

- Customization: Evaluate the manufacturer's ability to provide customized solutions, such as specific bag sizes, printing options, and special features.

- Pricing and Delivery: Compare quotes from various manufacturers, considering the PP Woven Bag price, shipping costs, and delivery times.

- Sustainability: Choose a manufacturer that adopts sustainable practices, such as using recycled materials or reducing waste.

- Reputation: Research the manufacturer's reputation and read reviews from other customers to gauge their reliability and service quality. View pp woven bags images from manufacturers to get a feel for their products.

Conclusion

The PP woven bags images are a robust and versatile packaging solution, crucial in numerous industries due to their strength, durability, and cost-effectiveness. The manufacturing process, diverse applications, market trends, and pricing dynamics all play a vital role in making these bags a packaging staple. PP woven bags represent a packaging solution that is not only cost-effective and durable but also adaptable to changing market demands and environmental considerations. For those who seek reliability and performance in packaging, the utilization of PP woven bags is a viable and sustainable solution.

Frequently Asked Questions

-

How does the strength of PP woven bags compare to other packaging materials like paper or HDPE bags?

PP woven bags are typically stronger than paper bags and provide a higher resistance to tearing and bursting. They also offer significantly better strength compared to HDPE (High-Density Polyethylene) bags, especially when dealing with heavy or bulky materials. The tensile strength makes them well-suited for demanding applications.

-

What is the typical lifespan of PP woven bags, and can they be reused?

The lifespan of a PP woven bag depends on factors like the usage conditions, the material being packaged, and the handling practices. They can last for a few uses, and, in some cases, even for multiple uses. Many businesses use them for their durability and reusability.

-

Are PP woven bags environmentally friendly, and how can they be recycled?

PP woven bags are recyclable, although the availability of recycling facilities varies by region. They are made from a single plastic, making the process more straightforward. The bags can be collected, cleaned, and shredded into PP pellets, which are then used to manufacture new PP products. Efforts for sustainability are increasing, and it's important for businesses to look for ways to reduce their carbon footprint.

-

How do I determine the correct bag size and weight capacity for my product?

Determining the proper bag size and weight capacity depends on the product's density, volume, and handling requirements. Measure the dimensions and weight of your product to establish the required bag size. Consider factors like fill height, stacking requirements, and the forces the bag will encounter during transportation and storage. The right bag size is important for effective packaging. Consult with a pp woven bag manufacturer to determine the right bag size and load-bearing capacity.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0