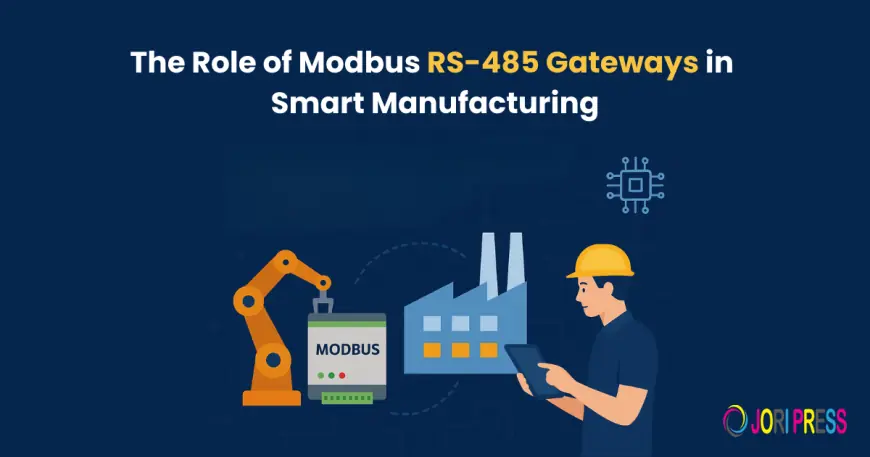

The Role of Modbus RS-485 Gateways in Smart Manufacturing

Learn how Modbus RS-485 Gateways in Manufacturing enable smart automation, seamless connectivity, and efficiency in modern industrial systems.

Smart manufacturing is transforming industrial operations by combining automation, IoT devices, and real-time analytics. However, integrating legacy industrial equipment with modern networks requires robust communication solutions, and Modbus RS-485 gateways serve as the essential bridge.

Introduction to Smart Manufacturing

Smart manufacturing refers to a production system where processes are interconnected, data-driven, and automated to maximize efficiency, reduce errors, and improve product quality.

-

Factories now leverage IoT sensors, robotics, and AI-driven analytics to monitor production in real-time.

-

Real-time data allows managers to track equipment performance, detect anomalies, and optimize operations dynamically.

-

A major challenge, however, is that many factories still use legacy machines with older communication protocols, which cannot natively connect to modern digital networks.

Without an interface like a Modbus RS-485 gateway, connecting these older devices to a smart manufacturing ecosystem would be nearly impossible, leaving a gap in data collection and system integration.

What is a Modbus RS-485 Gateway?

A Modbus RS-485 gateway is a device that enables communication between Modbus RTU/ASCII serial devices and modern Ethernet-based networks. It effectively converts the serial protocol of older machines to protocols compatible with SCADA, PLCs, or IoT systems.

Features:

-

Protocol Conversion: Converts serial data (Modbus RTU/ASCII) into Ethernet-based protocols like Modbus TCP/IP. This ensures that legacy machines can communicate with modern systems without replacing hardware.

-

Multi-Device Connectivity: Supports multiple RS-485 devices on a single network, making large-scale integration feasible.

-

Industrial-Grade Reliability: Designed to withstand high temperatures, dust, vibrations, and electromagnetic interference in factory settings.

-

Data Buffering & Management: Some advanced gateways can store data temporarily during network interruptions to prevent loss of critical operational information.

Importance of Modbus RS-485 Gateways in Industrial Automation

Modbus RS-485 gateways are vital for integrating legacy equipment with modern automation platforms. Here’s why they are indispensable:

-

Legacy System Integration: Many factories have machines installed decades ago that communicate only through RS-485 serial protocols. Gateways allow these devices to be part of modern IIoT networks without replacing the hardware.

-

Data Centralization: Gateways consolidate data from multiple devices into one location, enabling better monitoring, reporting, and analytics.

-

Remote Monitoring & Control: By converting data to network protocols, gateways allow operators to monitor and control equipment remotely, improving response times to issues.

-

Enhanced Decision-Making: Real-time data from gateways supports predictive maintenance, production optimization, and energy efficiency decisions.

Without gateways, manufacturers would face fragmented systems, slow decision-making, and underutilized data from legacy devices.

Key Applications in Smart Manufacturing

a. SCADA and HMI Integration

-

SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface) systems are used to monitor, visualize, and control industrial processes.

-

RS-485 gateways allow legacy devices to send real-time data to SCADA/HMI systems, enabling centralized control and alerts.

-

Example: A temperature sensor from 15 years ago can now provide live readings on a modern HMI panel, allowing operators to react immediately to anomalies.

b. Predictive Maintenance

-

By continuously collecting operational data, gateways enable predictive maintenance strategies.

-

Data such as motor vibrations, temperature, or pressure can be analyzed to predict failures before they happen, reducing downtime and maintenance costs.

-

Example: A pump showing early signs of wear can be serviced proactively, avoiding unexpected production stoppages.

c. IoT and IIoT Connectivity

-

Gateways convert serial data into network-ready formats, allowing devices to connect to IoT and IIoT platforms.

-

This makes legacy equipment part of a larger connected ecosystem, where analytics and AI can optimize production.

-

Example: A factory can monitor all machine performance metrics on a cloud dashboard, regardless of device age.

d. Energy Management

-

Energy consumption monitoring is critical for cost reduction and sustainability.

-

Gateways can collect power usage, temperature, or environmental data from legacy devices and feed it to energy management systems.

-

Example: Real-time monitoring can detect which machines are consuming excess power and trigger efficiency measures automatically.

e. Factory Automation

-

Gateways ensure that older equipment can communicate seamlessly with PLCs, robotic arms, and automated conveyors.

-

This enables synchronized, automated workflows, improving production speed and accuracy.

-

Example: A production line with mixed legacy and modern machines can operate in harmony, guided by a centralized control system.

Advantages of Using Modbus RS-485 Gateways

-

Cost-Effective Integration

-

Avoid costly replacement of legacy equipment.

-

Extend the life of existing machines while upgrading the network capabilities.

-

Enhanced Network Flexibility

-

RS-485 supports long-distance communication (up to 1200 meters).

-

Gateways allow connection of multiple devices over a single network segment.

-

Improved Data Accuracy

-

Gateways reduce errors from miscommunication between devices.

-

Reliable data ensures better analytics, reporting, and operational decisions.

-

Scalability

-

Easily add new devices or production lines.

-

The gateway acts as a hub, enabling expansion without significant rewiring or system redesign.

-

Remote Access and Monitoring

-

Access real-time machine data from anywhere.

-

Helps in proactive troubleshooting, reducing downtime and maintenance visits.

Implementation Best Practices

-

Proper Device Mapping: Correctly assign addresses to each RS-485 device in the gateway to ensure accurate data collection.

-

Network Segmentation: Separate production networks from IT networks to reduce congestion and improve security.

-

Firmware Updates: Regularly update gateway firmware to fix bugs, improve performance, and enhance security.

-

High-Quality Cabling: Use shielded twisted-pair cables to minimize signal interference in industrial environments.

-

Redundancy Planning: For mission-critical applications, deploy backup gateways to ensure continuous communication in case of failures.

Challenges and Solutions

Challenge 1: Protocol Incompatibility

-

Solution: Use gateways that support multiple protocols (Modbus RTU, ASCII, TCP/IP) and allow custom configuration.

Challenge 2: Communication Latency

-

Solution: Optimize polling intervals and network configuration to minimize delays.

Challenge 3: Harsh Industrial Environment

-

Solution: Use industrial-grade gateways with proper enclosures to protect against dust, heat, and vibration.

Future Trends in Gateway Technology

-

Cloud Integration: Gateways will increasingly send data directly to cloud platforms for real-time analytics.

-

Edge Computing: Some gateways will process data locally to reduce network load and provide instant insights.

-

Enhanced Security: Gateways will adopt advanced encryption, authentication, and cybersecurity measures.

-

AI-Driven Optimization: Smart gateways may detect anomalies and automatically optimize communication for better performance.

Conclusion

Modbus RS-485 gateways are a cornerstone of modern smart manufacturing. They enable legacy devices to integrate seamlessly with IoT, SCADA, and cloud platforms, enhancing operational efficiency, predictive maintenance, and automation. By bridging the old and the new, gateways ensure that factories can embrace Industry 4.0 without abandoning their existing investments.

FAQs

Q1: Can a Modbus RS-485 gateway connect multiple device types?

Yes, modern gateways can handle various serial devices and protocols simultaneously.

Q2: What is the maximum distance supported by RS-485 communication?

RS-485 supports distances up to 1200 meters (about 4000 feet) using appropriate cables.

Q3: Can RS-485 gateways integrate with cloud platforms?

Yes, by converting serial data to TCP/IP or Ethernet, gateways can transmit data to IoT and cloud systems.

Q4: How often should gateway firmware be updated?

It is recommended to check and update firmware every 6–12 months for security and performance.

Q5: Do gateways improve production efficiency?

Absolutely. They enable real-time monitoring, predictive maintenance, and seamless automation, reducing downtime and operational inefficiencies.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0