The Growing Demand for Automation Equipment CNC Parts in Modern Manufacturing

Explore how automation equipment CNC parts drive efficiency and precision in industrial automation. Learn their applications, benefits, and future trends in manufacturing.

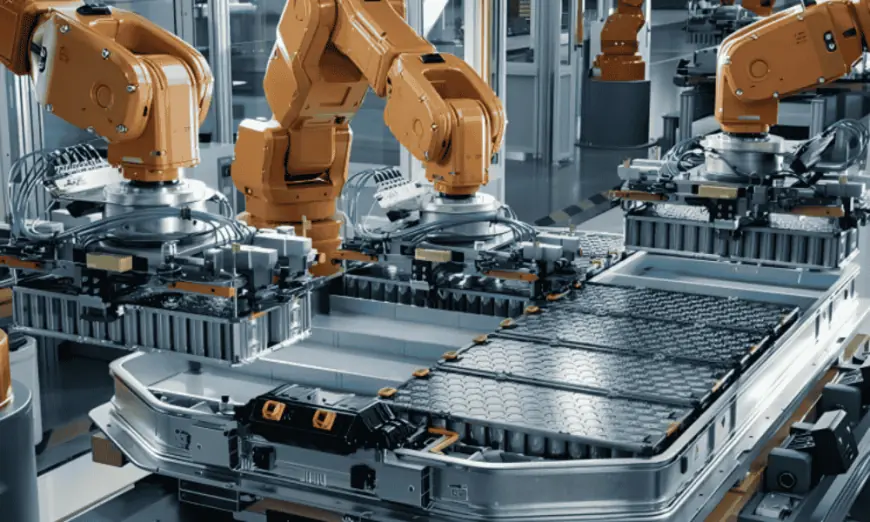

As automation continues to reshape industries worldwide, the demand for precision-manufactured components has never been higher. In particular, automation equipment CNC parts play a pivotal role in enabling efficient, reliable, and scalable automated processes. Whether it’s robotics, assembly lines, or smart systems, CNC (Computer Numerical Control) machining ensures each part meets exact specifications for seamless integration into automated workflows. This article delves into the significance of CNC parts in automation, the industries benefiting from them, and why investing in quality CNC machining is essential for staying competitive.

What Are Automation Equipment CNC Parts?

Automation equipment CNC parts are components manufactured using computer-controlled machining tools that offer unparalleled precision. These parts are typically made from metal or plastic and include items such as brackets, housings, shafts, custom fittings, and connectors used in robotic arms, conveyor systems, pick-and-place machines, and automated testing equipment.

CNC machining allows for repeatability, tight tolerances, and high-quality finishes that are critical in automation. The ability to design parts down to the micrometer ensures equipment functions optimally without the risk of mechanical failure or misalignment.

The Role of CNC Machining in Industrial Automation

1. Consistency and Precision

One of the most significant advantages of CNC machining in automation is the ability to produce identical parts at scale. In automated systems where the margin for error is minimal, precision parts prevent costly downtimes and maintenance.

2. Customization

Automation systems vary widely based on the application. CNC machining supports custom part manufacturing, enabling businesses to tailor components that perfectly match their machinery and processes.

3. Material Versatility

From stainless steel and aluminum to advanced plastics and composites, CNC machines can work with a wide range of materials. This versatility allows industries to select the best material for the environment—whether it involves heat, chemicals, or mechanical stress.

Key Industries That Rely on Automation Equipment CNC Parts

1. Automotive Industry

Automated assembly lines in car manufacturing heavily depend on CNC parts for robotic welding, part placement, and inspection systems. These components must withstand repetitive stress while maintaining precise function.

2. Aerospace and Defense

In aerospace, where safety and accuracy are non-negotiable, CNC machined parts ensure that automated testing systems and manufacturing tools perform flawlessly under extreme conditions.

3. Electronics and Semiconductors

The electronics sector demands ultra-precise components for surface-mount technology (SMT) and circuit assembly lines. CNC parts play a critical role in maintaining speed and alignment.

4. Medical Devices

Medical automation, such as diagnostic and surgical systems, relies on CNC-machined components for reliability and cleanliness. The ability to produce sterile and consistent parts is vital in healthcare.

5. Packaging and Logistics

CNC parts in automated packaging machines enhance speed, accuracy, and durability. These parts support functions such as labeling, sealing, filling, and palletizing.

Advantages of Using CNC Parts in Automation Equipment

Precision Manufacturing

Tolerances as tight as ±0.001 inches can be achieved with CNC machines, making them ideal for automated systems where even a small deviation can halt operations.

Reduced Human Error

Automated CNC processes eliminate manual intervention, reducing the risk of human error during the production of complex parts.

Faster Time to Market

With CNC prototyping and fast turnaround, manufacturers can test, iterate, and launch automation solutions faster than with traditional manufacturing methods.

Cost Efficiency Over Time

Although CNC machining has upfront costs, its precision reduces waste, maintenance, and machine downtimes—leading to long-term savings.

Design Considerations for CNC Parts in Automation

When designing CNC parts for automation equipment, manufacturers must account for:

-

Functionality: Ensuring the part can withstand repetitive motion and high-speed operations.

-

Assembly Compatibility: Custom designs should align seamlessly with existing hardware and systems.

-

Environmental Tolerance: Parts must be designed to endure vibration, temperature changes, and potential chemical exposure.

-

Ease of Replacement: Modular and standardized designs simplify part replacement and reduce downtime.

Collaborating with experienced CNC machinists ensures these criteria are met without compromising on quality or performance.

The Future of CNC in Automation

As automation trends evolve, so does the complexity of the required components. The integration of AI, IoT, and machine learning in manufacturing demands parts that support sensors, smart controls, and adaptive interfaces.

Emerging materials, such as carbon composites and advanced polymers, are also being adapted for CNC machining, providing lightweight yet strong solutions for high-performance automation systems.

Moreover, multi-axis CNC machines and hybrid manufacturing methods (e.g., combining additive and subtractive processes) are making it possible to produce intricate parts with internal features previously considered impossible.

Partnering with a CNC Specialist for Automation Success

Finding the right CNC machining partner is critical. A capable provider understands the intricacies of automation requirements, offers prototyping services, and ensures quality control through every stage of production.

Key factors to look for in a CNC machining partner:

-

Experience with automation systems and industries

-

Advanced CNC equipment and software

-

Customization capabilities

-

Quality assurance protocols (e.g., ISO certifications)

-

Transparent communication and support

By collaborating with an expert manufacturer, businesses can ensure their automation investments are backed by reliable and efficient components.

Conclusion

In the era of smart factories and industrial automation, precision parts are the foundation of success. Automation equipment CNC parts ensure seamless, efficient, and accurate operation across diverse industries. From material selection to complex design specifications, CNC machining empowers businesses to innovate, scale, and compete in a fast-paced digital world.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0