Revolutionizing Food Safety and Packaging with eBeam Technologies

In the food industry, ensuring the safety, quality, and longevity of products is paramount. As consumer demands for fresh, preservative-free foods continue to rise, the need for advanced, sustainable packaging solutions has become more critical than ever. Traditional food sterilization and packaging methods, while effective, often rely on heat or chemicals that can compromise the food’s flavor, texture, or nutritional value. Moreover, the environmental impact of these conventional methods, especially plastic packaging, contributes to the growing concerns over waste and pollution.

This is where eBeam technologies come into play. By utilizing electron beams to sterilize food packaging materials and even the food itself, eBeam technologies offer an innovative solution that can help reduce the reliance on harmful chemicals and high temperatures. This method ensures that food packaging remains sterile, all while preserving the integrity and freshness of the product inside.

For more information about how eBeam technologies are changing the food packaging landscape.

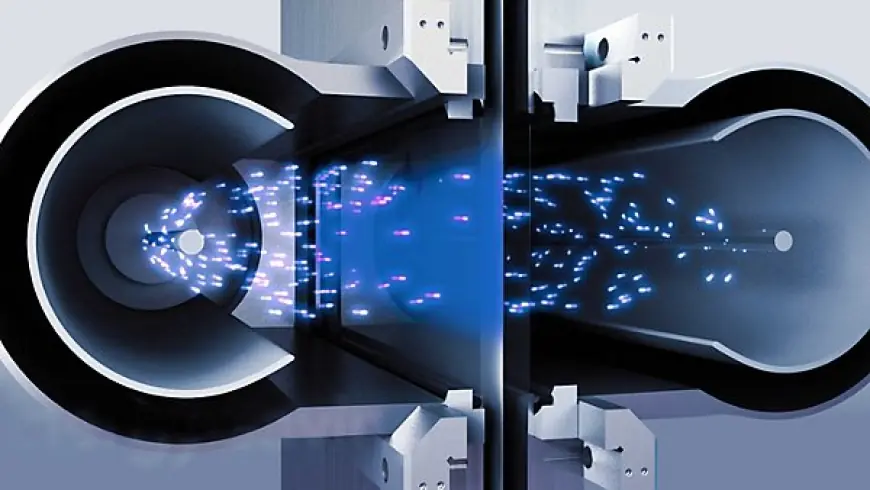

The Science Behind eBeam Technologies in Food Packaging

eBeam technologies work by using a stream of high-energy electrons to alter the properties of materials without the need for heat or chemicals. When applied to food packaging, these electron beams penetrate the materials, sterilizing them without affecting the food’s contents. This process can be used to kill bacteria, fungi, and other harmful microorganisms that may compromise food safety. The beauty of eBeam sterilization is that it doesn't rely on chemicals, which are often harmful to the environment and can leave residual traces on the food or packaging.

Moreover, eBeam technologies are highly efficient, allowing for rapid sterilization and treatment of materials. This not only speeds up the production process but also reduces the overall energy consumption compared to conventional methods that require high heat or lengthy processing times.

Benefits of eBeam Technologies in Food Packaging

-

Enhanced Food Safety One of the primary benefits of eBeam technologies is their ability to enhance food safety. By sterilizing packaging materials and food products themselves, electron beams kill harmful microorganisms, such as bacteria and viruses, without leaving any chemical residues. This reduces the risk of contamination and extends the shelf life of perishable items like meat, dairy, and fresh produce.

-

Improved Quality and Freshness Traditional sterilization techniques that use heat can alter the taste, texture, and nutritional value of food. For example, pasteurization can result in cooked or over-processed foods, which can compromise their freshness. With eBeam sterilization, however, the temperature remains low, meaning the food retains more of its original qualities, from flavor to nutritional content.

-

Sustainability The environmental impact of food packaging is a growing concern, especially with the rise of plastic waste. eBeam technologies help tackle this issue by reducing the need for chemical treatments, thus minimizing harmful emissions. Additionally, because electron beams use minimal energy, they are an environmentally friendly alternative to traditional heat-based sterilization methods, which can consume significant amounts of electricity.

-

Extended Shelf Life The use of eBeam technologies not only sterilizes the packaging but also helps to preserve the freshness of the food within. By extending shelf life, eBeam-treated food can travel further distances without the risk of spoilage, which is especially beneficial for international trade and long-term storage. This added shelf life can reduce food waste, a significant issue globally, particularly in developing nations where food preservation infrastructure is limited.

-

Cost-Effective Although the initial investment in eBeam technology can be higher than conventional methods, the long-term savings make it a cost-effective choice. With quicker processing times, reduced energy consumption, and less reliance on chemicals and packaging materials, eBeam sterilization presents a significant cost-saving opportunity for food producers.

-

Versatility eBeam technologies are not limited to one type of food or packaging material. They can be used across a wide range of food products, including fresh produce, packaged meats, dairy, and even ready-to-eat meals. Similarly, electron beams can treat a variety of packaging materials, from plastics to glass and metal. This versatility makes eBeam an appealing solution for large-scale food manufacturers.

The Future of Food Packaging with eBeam Technologies

As consumer demand for cleaner, greener, and more efficient food packaging continues to rise, eBeam technologies are positioned to play a critical role in the future of food safety and packaging. As the technology evolves, we can expect even more efficient systems with faster processing times, lower costs, and broader applications. Additionally, as sustainability becomes more of a focal point for companies worldwide, eBeam will continue to offer a cleaner alternative to traditional sterilization methods.

At the same time, as the food industry seeks to meet stringent regulatory standards for packaging and food safety, the ability to rely on a technology like eBeam—which sterilizes without the use of chemicals—will only become more attractive. As a non-thermal process, eBeam also helps to preserve the natural state of food, reducing the need for additives or preservatives, which is a key concern for many consumers.

For manufacturers looking to invest in the future of food packaging, eBeam technologies offer a compelling solution that is both innovative and sustainable. By integrating electron beam sterilization into their production lines, food companies can improve product safety, increase operational efficiency, and contribute to a cleaner, more sustainable planet.

Conclusion

The food packaging industry stands at a crossroads, where innovation, safety, and sustainability are more critical than ever. eBeam technologies are making a significant impact by offering a fast, energy-efficient, and environmentally friendly method for sterilizing packaging and food products. With benefits ranging from improved food safety and quality to reduced environmental impact and longer shelf life, eBeam technologies are helping to reshape the future of food packaging. As consumer demand for sustainable practices continues to grow, eBeam will undoubtedly play a central role in shaping the food industry’s approach to packaging and sterilization in the years to come.