Off-Grid Solar Panel System for Industrial Facilities | Complete Power Guide

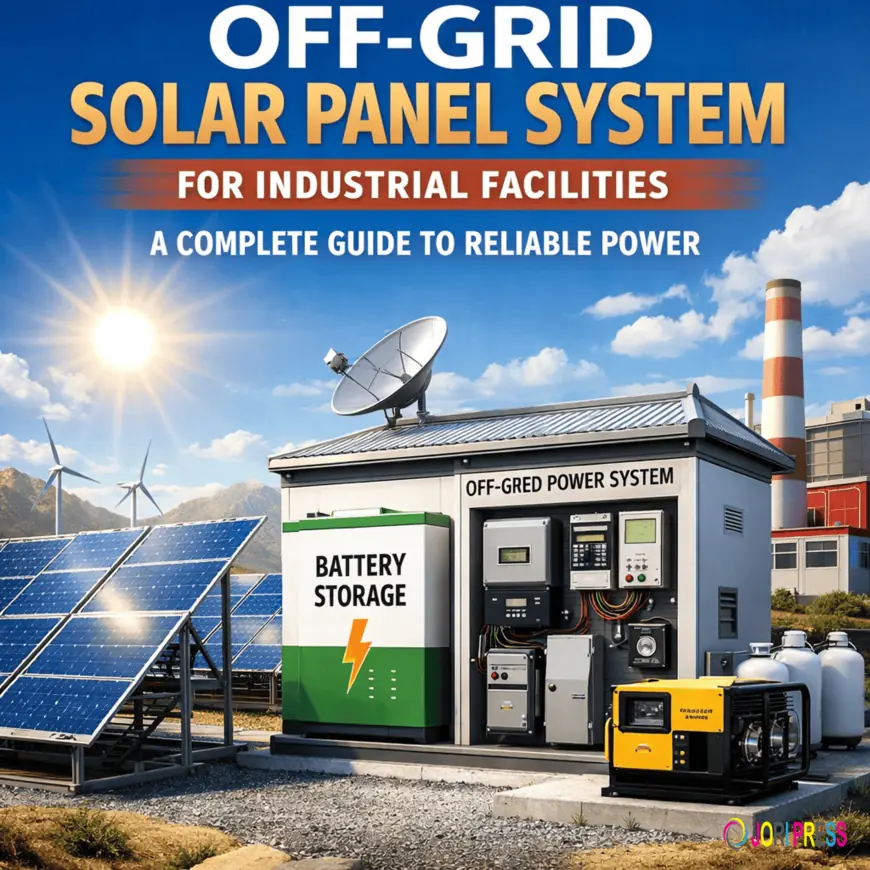

Learn how an off-grid solar panel system for industrial facilities provides reliable power without grid dependence. This complete guide explains system components, capacity planning, benefits, costs, and maintenance for industrial use.

Industries need uninterrupted and reliable power to operate machines, maintain productivity, and avoid costly downtime. In many regions, grid electricity is either unreliable, unavailable, or too expensive for industrial operations. This is where an off-grid solar panel system for industrial facilities becomes a powerful and practical solution.

An off-grid solar system allows an industrial facility to generate and store its own electricity without depending on the utility grid. This guide explains everything you need to know about industrial off-grid solar systems, including how they work, key components, system sizing, benefits, costs, and maintenance.

What Is an Off-Grid Solar Panel System?

An off-grid solar panel system is a self-sufficient power system that operates independently from the electricity grid. It generates electricity using solar panels and stores excess energy in batteries for use during night-time or cloudy days.

For industrial facilities, off-grid systems are designed to handle:

-

high power loads

-

continuous operations

-

critical equipment

Unlike on-grid systems, off-grid solar systems include battery storage and backup planning to ensure reliable power at all times.

Why Industries Choose Off-Grid Solar Power

Industrial facilities adopt off-grid solar systems for several important reasons.

1. Reliable Power Supply

Off-grid systems provide uninterrupted electricity, even in areas with frequent power cuts or no grid access.

2. Independence from the Grid

Industries avoid dependency on unstable or expensive utility power.

3. Long-Term Cost Savings

After installation, solar energy significantly reduces fuel and electricity costs.

4. Suitable for Remote Locations

Ideal for factories, mining sites, and processing plants located far from grid infrastructure.

5. Environmental Compliance

Solar power helps industries meet sustainability goals and reduce carbon emissions.

Key Components of an Industrial Off-Grid Solar System

An off-grid solar system for industrial use includes several critical components.

1. Solar Panels

Solar panels capture sunlight and convert it into electricity.

Industrial facilities usually use:

-

high-efficiency monocrystalline panels

-

heavy-duty panels designed for long-term use

Panels are installed on rooftops, ground-mounted structures, or open land within the facility.

2. Solar Inverter

The inverter converts DC electricity from solar panels into AC electricity used by industrial machines.

Industrial off-grid systems use:

-

high-capacity off-grid inverters

-

multiple inverter configurations for load sharing

3. Battery Bank

Batteries store excess solar energy for use when sunlight is not available.

Common battery types:

-

lithium-ion batteries (longer life, higher efficiency)

-

tubular or industrial lead-acid batteries

Battery capacity is critical for maintaining continuous industrial operations.

4. Charge Controller

The charge controller regulates the flow of electricity between solar panels and batteries, preventing overcharging and deep discharge.

5. Backup Generator (Optional but Recommended)

Many industrial off-grid systems include a diesel or gas generator as an additional backup for extended cloudy periods or peak demand.

6. Earthing and Protection System

Includes:

-

earthing rods

-

surge protection devices

-

circuit breakers

These protect equipment and ensure system safety.

How an Off-Grid Solar System Works in an Industrial Facility

-

Solar panels generate electricity during the day

-

Power is supplied directly to industrial loads

-

Excess electricity charges the batteries

-

Stored energy powers operations at night or during low sunlight

-

Backup generator supports the system when required

This design ensures reliable power availability at all times.

System Size Planning for Industrial Off-Grid Solar

Correct system sizing is essential for industrial facilities.

Factors to Consider:

-

total connected load (kW)

-

daily energy consumption (kWh)

-

operating hours (single shift or 24/7)

-

critical vs non-critical loads

-

battery backup duration required

Example:

-

Small industrial unit: 30–50 kW

-

Medium factory: 100–250 kW

-

Large industrial facility: 500 kW or more

A professional energy audit is recommended before finalizing system size.

Advantages of Off-Grid Solar for Industrial Facilities

1. Continuous Operations

No production loss due to power outages.

2. Reduced Operating Costs

Lower diesel consumption and electricity bills.

3. Scalability

Systems can be expanded as industrial demand grows.

4. Long Equipment Life

Stable power supply protects sensitive machinery.

5. Energy Security

Industries control their own power generation.

Challenges of Industrial Off-Grid Solar Systems

While highly beneficial, off-grid systems also have challenges.

-

higher initial investment

-

battery replacement costs

-

space requirement for panels and batteries

-

professional design and maintenance required

Proper planning and quality components minimize these challenges.

Approximate Cost of Industrial Off-Grid Solar Systems

Costs depend on:

-

system capacity

-

battery type and size

-

inverter quality

-

installation complexity

Off-grid systems are more expensive than on-grid systems due to battery storage, but they offer unmatched reliability in return.

Maintenance Requirements

Industrial off-grid solar systems require regular maintenance.

Key Maintenance Tasks:

-

cleaning solar panels every 2–4 weeks

-

monitoring battery health

-

checking inverter performance

-

inspecting wiring and earthing

-

servicing backup generator

Proper maintenance ensures 20–25 years of system life.

Off-Grid Solar vs Diesel Generator for Industries

|

Factor |

Off-Grid Solar |

Diesel Generator |

|

Fuel cost |

No |

High |

|

Maintenance |

Low |

High |

|

Noise |

Silent |

Noisy |

|

Pollution |

None |

High |

|

Long-term cost |

Lower |

Higher |

Many industries use solar with generators only as emergency backup.

Is Off-Grid Solar Right for Your Industrial Facility?

Off-grid solar is ideal if:

-

grid power is unreliable or unavailable

-

diesel costs are high

-

long-term energy savings are a priority

-

sustainability goals are important

A detailed feasibility study helps determine suitability.

Final Conclusion

An off-grid solar panel system for industrial facilities is a reliable, cost-effective, and future-ready power solution. It provides energy independence, reduces operational costs, and ensures uninterrupted production even in remote or power-deficient areas.

With proper system design, quality components, and regular maintenance, industrial off-grid solar systems can deliver stable power for decades. As energy costs continue to rise, investing in off-grid solar is not just an alternative—it is a strategic business decision for long-term industrial growth.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0