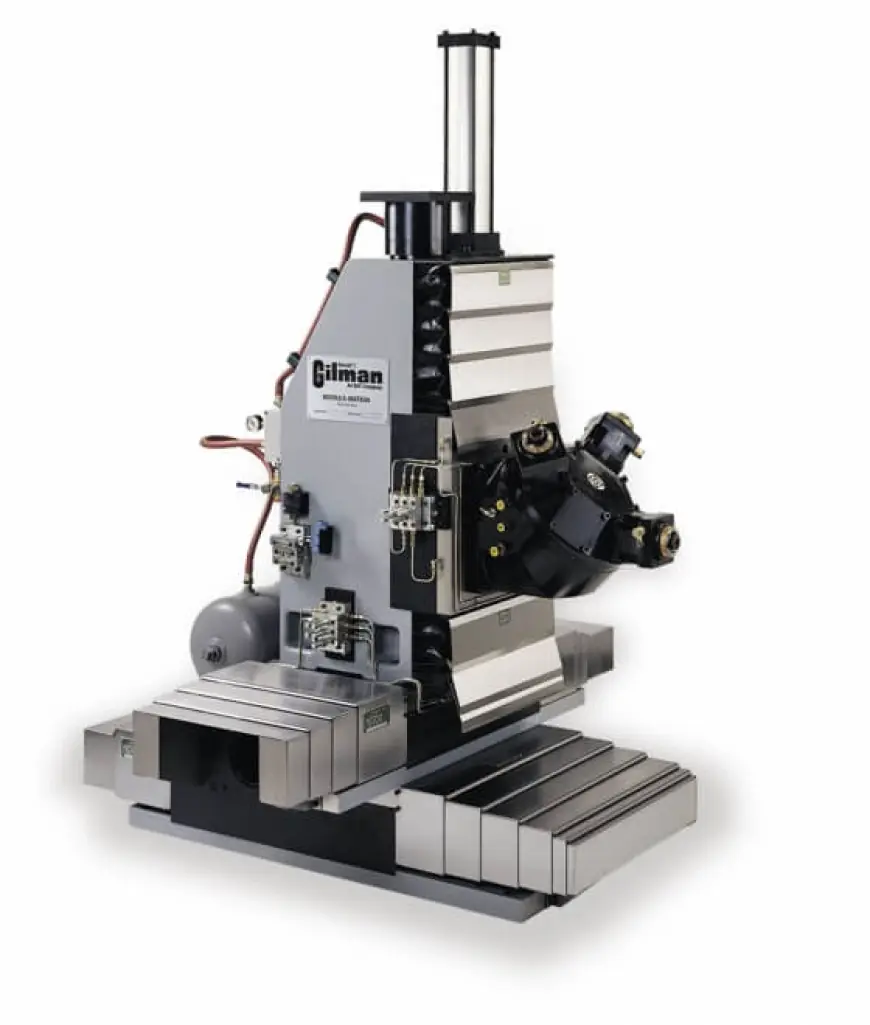

High-Precision Machine Modules for Customized Manufacturing Solutions

Gilman Precision designs and manufactures machine modules that deliver reliable, accurate, and efficient motion control for a wide range of industrial applications.

Gilman Precision designs and manufactures machine modules that deliver reliable, accurate, and efficient motion control for a wide range of industrial applications. These precision-engineered modules combine linear and rotary motion elements into integrated assemblies, simplifying installation and enhancing machine performance. By offering customizable configurations, Gilman’s machine modules provide the perfect solution for manufacturers who need tailored systems that improve productivity, reduce downtime, and extend equipment life.

Advanced Engineering for Machine Modules

Integrated Motion Solutions

Gilman’s machine modules combine precision slides, spindles, and drive systems into one complete assembly. This integrated approach reduces complexity, improves alignment, and simplifies installation compared to sourcing individual components.

Optimized for Accuracy and Longevity

Each module is engineered with high-quality materials and precision-ground components, ensuring smooth motion, long-lasting durability, and minimal maintenance. These modules are designed to perform reliably in demanding industrial environments.

Types of Machine Modules

Linear Motion Modules

Linear motion modules include precision slides and stages designed for smooth, accurate travel. These modules can feature dovetail slides, hardened box way slides, or linear guide slides, customized to meet specific travel lengths, load capacities, and mounting requirements.

Rotary Motion Modules

Rotary motion modules integrate high-performance spindles or rotary tables to provide controlled rotational movement. These modules are ideal for milling, grinding, drilling, and other applications that require precise rotary motion.

Combined Linear and Rotary Modules

For complex operations, Gilman offers machine modules that combine linear and rotary motion in one assembly. This allows for multi-axis movement within a compact, easy-to-install system, improving flexibility and operational efficiency.

Benefits of Machine Modules

Simplified Installation and Integration

By combining multiple motion elements into one assembly, Gilman’s machine modules reduce installation time and ensure proper alignment. This helps minimize setup errors and improves overall machine performance.

Enhanced Accuracy and Reliability

Because machine modules are designed and assembled as complete systems, they deliver improved accuracy, smoother motion, and higher reliability compared to separate components that require manual integration.

Reduced Maintenance and Downtime

Integrated modules have fewer alignment and compatibility issues, which reduces wear and maintenance needs. This leads to less downtime and longer service life for your equipment.

Flexible and Customizable Solutions

Gilman’s machine modules are available in standard configurations or can be fully customized to meet unique application requirements, ensuring optimal performance for specific processes.

Applications of Machine Modules

CNC Machines and Automated Systems

Machine modules improve the performance and flexibility of CNC machining centers, automated production lines, and robotic systems by delivering precise linear and rotary motion in one integrated package.

Aerospace and Automotive Manufacturing

In industries that require high accuracy and repeatability, customized machine modules support complex machining and assembly operations with superior reliability.

Medical Device and Electronics Production

For delicate, high-precision manufacturing, machine modules provide stable, repeatable motion control that ensures consistent quality for small and intricate components.

Heavy-Duty Industrial Equipment

Machine modules designed for heavy loads and long travel distances support large-scale manufacturing processes while maintaining high accuracy and stability.

Customization Options for Machine Modules

Travel Length and Load Capacity

Gilman customizes each machine module to the required travel length and load capacity, ensuring it meets the exact demands of the application.

Drive Systems and Controls

Machine modules can be equipped with various drive options, including ball screws, rack-and-pinion drives, servo motors, or stepper motors. Integration with advanced control systems allows for automated, programmable motion.

Material and Mounting Configurations

Modules can be manufactured with different materials and mounting patterns to match the specific operating environment, whether it’s a clean room, high-speed production line, or heavy-duty shop floor.

Design and Manufacturing Process for Machine Modules

Collaborative Engineering Support

Gilman’s engineering team works closely with customers to design machine modules that fit seamlessly into their existing equipment and processes. This collaborative approach ensures the module meets all functional and performance requirements.

Precision Manufacturing and Assembly

Each module is manufactured using advanced machining and grinding techniques, ensuring all components meet strict tolerances. Modules are assembled with care to achieve perfect alignment and smooth operation.

Rigorous Testing and Validation

Before delivery, every module undergoes extensive testing to verify its accuracy, load capacity, vibration resistance, and smooth motion. This ensures long-term reliability and trouble-free integration into your machinery.

Maintenance and Service for Machine Modules

Long-Term Reliability

Gilman’s machine modules are designed for long-term performance with minimal maintenance. Proper lubrication and periodic inspection keep them running smoothly for years.

Rebuild and Repair Services

If a machine module experiences wear over time, Gilman offers professional rebuild and repair services to restore it to original specifications, extending the life of your investment.

Why Choose Gilman Precision for Machine Modules

Decades of Motion Control Expertise

With more than 70 years of experience in linear and rotary motion technology, Gilman Precision is a trusted leader in designing and manufacturing machine modules for a variety of industries.

Proven Quality and Reliability

Each machine module is built to the highest quality standards, ensuring dependable performance in even the most demanding industrial environments.

Flexible, Tailored Solutions

Gilman provides both standard and fully customized machine modules, offering the flexibility to meet unique application needs without compromise.

Complete Support from Design to Service

From initial concept and design to manufacturing, testing, installation, and ongoing support, Gilman delivers comprehensive service throughout the entire lifecycle of your machine module.

Improve Equipment Performance with Precision Machine Modules

When you need reliable, integrated motion solutions, Gilman Precision delivers machine modules that combine accuracy, durability, and flexibility in one engineered package. These modules simplify installation, improve machine performance, and reduce long-term maintenance costs.

Whether you require a linear motion module, a rotary spindle assembly, or a fully customized multi-axis system, Gilman has the expertise and technology to create the ideal solution for your application. By choosing Gilman Precision, you gain a trusted partner committed to improving your manufacturing efficiency and productivity with high-performance machine modules.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0