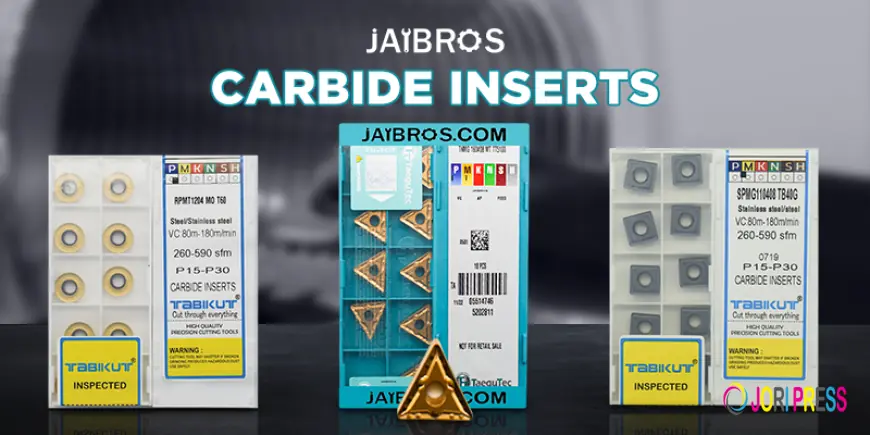

Buy High-Performance Carbide Inserts for Precision Cutting

Shop premium carbide inserts for CNC machining, smooth cutting, and longer tool life. Order now for high accuracy, durability, and better performance.

Carbide Inserts: The Backbone of Modern Machining Precision

Carbide inserts are essential in the manufacturing industry as they allow for the creation of high-quality, consistent, and efficient product components that can be manufactured from metals. Carbide inserts have paved the way in producing automotive and aerospace parts and have greatly improved manufacturing processes in terms of both speed and reliability, ultimately reducing costs. Machining processes involving the use of carbide inserts create much more precision in part machining (i.e., turning, milling, or drilling) and have also created an overall improvement in the efficiency of machining.

As high-speed machining continues to gain popularity in the manufacturing sector, CNC carbide inserts will continue to provide companies with substantial productivity improvements while extending the life of their tooling. Knowing which type of insert to use for your machining process will require an understanding of the different types of carbide inserts available, their specific applications, and their associated specifications.

What Are Carbide Inserts?

Carbide Inserts are created from the same material as Cemented Carbide (a combination of tungsten carbide particles, bonded with Cobalt). Inserts are fitted onto toolholders in many different styles of machines, including lathes, milling machines, and CNC machining centers. The inserts can either be rotated or replaced, depending on how much wear there is; this reduces the amount of time that a machine is down (i.e., not being used) and increases the machine's productivity.

Carbide Inserts are an excellent choice for cutting some of the hardest materials available because of their superior hardness, their excellent heat resistance, and their great resistance to wear. Examples of some of the hardest materials are: stainless steel, cast iron, and hardened alloys.

Role of CNC Carbide Inserts in High-Speed Machining

Today's CNC machinery is designed to be both fast and precise, and the insert materials used with these machines are also designed specifically for use in conjunction with them. Because CNC inserts provide a measure of precision and quality (which are both extremely important in today's manufacturing environment), they will perform in the manner specified throughout a large manufacturing run (from one long batch of manufacturing to another long batch of manufacturing).

Manufacturers that utilise CNC carbide inserts on their computer-controlled equipment will often remove metal at much higher rates (and thus produce finished parts faster) than those manufacturing tools that utilise other types of tooling. In addition, carbide inserts maintain very tight tolerances while still being able to remove large amounts of metal very quickly. Due to the high wear-resistance and high-temperature tolerance of CNC carbide inserts, they last much longer than comparable tool materials, which decreases the amount of time spent retooling, thereby increasing overall productivity.

Understanding the Carbide Inserts Chart

When choosing the right carbide insert for a machining operation, one should rely upon a carbide insert chart. This chart provides your machine shop with detailed specifications of insert geometry, shape, size, clearance angle and tolerance class. When you understand the information provided in the carbide insert chart, you will be able to determine which insert will work best for the machining task and the workpiece material you have selected.

Each insert shape (triangular, square, round and diamond) has a specific function to meet a particular cutting requirement and create an appropriate surface finish and strength. The thickness and nose radius of the insert affect surface finish and strength, whereas clearance angles have an impact on the cutting performance of the tool. The use of a carbide insert chart will help you ensure that you achieve the best performance from your cutting tool, and it will help to reduce the risk of failure.

Applications of Carbide Inserts in Various Industries

Carbide inserts can be used in a variety of applications because of their durability and versatility across different sectors. The automotive industry uses carbide inserts to manufacture engine parts (such as blocks), various transmission components (e.g., gears) and other related assemblies as well. Aerospace manufacturers rely on carbide inserts for the machining of high-strength alloy components (such as wings) as well as the manufacture of precision machined components (such as engine manifolds).

In addition to the automotive and aerospace sectors, carbide inserts are also used extensively in the oil and gas industries for machining heavy-duty equipment parts (e.g., drilling rigs) and by general engineering shops for routine metal machining (i.e., cutting). Carbide inserts are essential tools in modern manufacturing processes because they can machine all types of metal (e.g., stainless steel, cast iron and hardened steel) at the same time.

Advantages of Carbide Insert Tools

Carbide insert tooling has many advantages when used for operations. For example, you can save on overall tooling expense because only the insert will need to be replaced rather than the complete tool, and because of their quick-change ability, less downtime is experienced by your machinery, as well as increased productivity. Finally, since the cutting edges are precision-ground, you will get consistent results when machining different materials and receive an improved surface finish.

Since carbide inserts maintain hardness at elevated temperatures compared to alternative materials, they can be used for high-speed cutting, excellent chip control and greater efficiency when machining.

Selecting the Right Carbide Insert

When choosing the right carbide insert for your machining job, consider these three points: the material being machined, how the machining will take place (the process); and what machine will be used to do the work. Cutting speed, feed rate, and depth of cut will also all play a role in determining which insert you should use. Some charts show the required geometry and grade of an insert for good performance on a specific machining job. Properly selecting an insert can increase overall productivity and efficiency, enhance tool life, and produce improved finish quality on the machined part.

Growth of Carbide Inserts Manufacturers in India

The rapid expansion of the tooling industry in India has resulted from the growth of a large number of carbide insert producers who are manufacturing carbide tooling products that meet international standards, using new coating technologies that exceed the quality of global competitors; precision-engineered tooling that enables them to manufacture at significantly lower costs than any other competitor in the world; and innovatively designed and implemented cost-effective manufacturing processes.

The competitive edge for these manufacturers lies in three areas: price, the diversity of carbide inserts varying from product categories, and their capability of servicing both local and global customers.

Maintenance and Best Practices

To get the most life out of your carbide insert tooling, the most important thing you can do is handle and maintain your inserts properly. By following manufacturer-recommended cutting speeds and feeds, using proper clamping techniques, and minimising vibration, you will optimise tooling performance. Regularly checking the condition of your inserts will allow you to detect any wear before it damages your workpiece or machine.

By adhering to recommended practices for using carbide tools, you will produce more efficient machining operations and have consistent quality from your parts.

Future Trends in Carbide Inserts Technology

The advancement of coatings technology, along with the advancement of material science, is changing the future of carbide insert technology. Nano-coatings and improved carbide grades will result in more resistant inserts to wear, as well as better thermal properties. In addition, new smart manufacturing systems are also incorporating tool monitoring systems to predict the rate of tool wear and improve the efficiency of tool usage.

Continued advancements in these areas will lead to continued improvements in both machining efficiencies and sustainability, increasing the importance of carbide inserts into the future as a machining component.

About Jaibros

Jaibros has established itself as a leading source of industrial tooling and machining solutions due to its dedication to meeting high standards of reliability, quality and performance. Its main goal is to provide durable and reliable tools for current manufacturers that will result in increased productivity, improved accuracy and prolonged operational success. With a strong emphasis on customer service and innovative product design, Jaibros’ products will enable the many different types of industries to meet their modern-day demands.

Conclusion

Carbide Inserts have emerged as one of the most important foundations for machining in today's age because of their strength, durability and precision. Carbide Inserts are used in CNC machines or specialised carbide insert tooling systems, which create efficiencies in different industries. To achieve maximum success in your machining operation, you should use trusted carbide insert manufacturers in India and review your performance using a Carbide Inserts chart. With advancements in technology, the role of carbide inserts will be a vital piece in ensuring industry growth and manufacturing achievement.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0