Axial Piston Motors: Powering Equipment in Various Industries

Axial piston motors are a type of swash plate actuator that converts hydraulic fluid pressure and flow into mechanical motion.

Working Principle of Axial Piston Motors

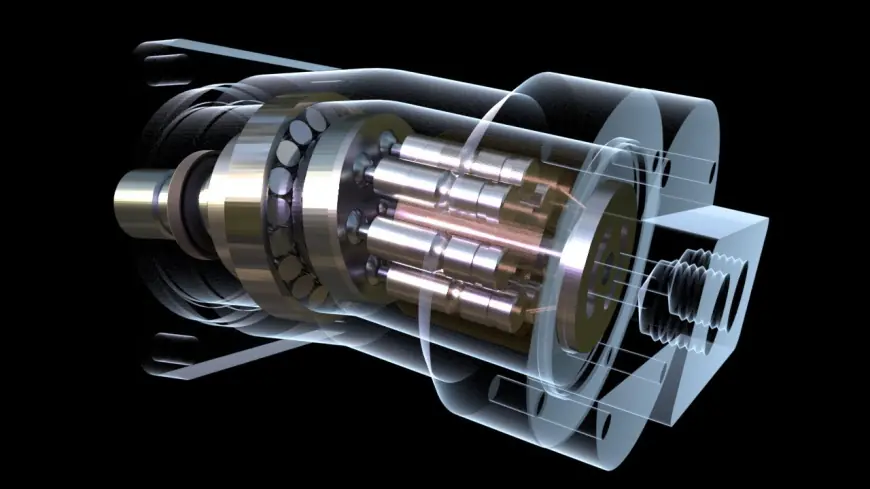

Axial piston motors work on the principle of converting hydraulic energy or pressure into mechanical rotational motion. In these motors, several pistons are arranged around a cylindrical rotor in a symmetrical way and move linearly as the rotor turns. Hydraulic fluid under high pressure enters one side of each piston chamber forcing the piston to move to the other side. This pushing and pulling action of the pistons as the rotor turns results in torque and rotational motion. The pistons act against inclined swash plates inside the motor which translates the linear motion of pistons into angular movement.

Design and Construction

Axial piston motors have a relatively simple yet robust design that allows their use in heavy-duty applications. The core components include a cylindrical rotor, pistons, swash plate, valve plates and a casing. The rotor has passages to allow hydraulic fluid circulation. The pistons are fitted into bores inside the rotor and connected to shoes that push against the inclined swash plate. The valve plates contain distribution ports and channels to direct pressurized fluid into and out of the piston chambers. The casing houses all internal components and maintains hydraulic pressures. Some motors feature variable swash plates whose angle can be adjusted to vary the output speed.

Uses in Mobile Equipment

Axial Piston Motors are widely used to power hydraulics in heavy construction, agricultural, mining and other off-highway mobile equipment. Their high torque output, compactness and ability to function reliably in harsh environments make them well-suited for these applications. Common uses include powering excavators, cranes, backhoes, harvesters, bulldozers, wheel loaders, forklifts etc. Through variable displacement designs, the motors can operate hydraulic pumps, motors or actuators with precisely controlled speed and force outputs as per the equipment's working requirements. This ensures smooth and efficient operation of hydraulic circuits.

Industrial Applications

Besides mobile machinery, axial piston motors also find applications in several stationary industrial processes and machinery that requires hydraulic power transmission. Examples include presses, extruders, injection moulding machines, hydraulic presses, power packs etc. Their ability to deliver high torque over a wide speed range even at low hydraulic pressures expands their use in automation equipment, marine hydraulic systems and offshore drilling rigs. Some special industrial motors have customized features like higher pressure and temperature ratings, noise dampening, biodegradable fluid compatibility etc. tailored for demanding industrial environments.

Advantages over Other Motor Designs

Compared to radial piston and bent axis piston hydraulic motors, axial piston motors offer better load handling capability, higher torque density and more compact packaging. Their balanced design lets them operate smoothly with less vibrations. Axial piston motors also have an edge over gear motors and electrically driven pumps in situations requiring functional safety, zero emissions and flexibility to power complex hydraulic circuits. Variable displacement versions provide efficient speed and power control without wasteful leakage losses at lower outputs. Overall the robust construction, versatility and reliability of axial piston motors have made them a staple in mobile and industrial hydraulic applications.

Continuous Technological Advances

Technology companies are continuously working on improving the performance and functionality of axial piston motors. Newer designs feature components made from advanced wear-resistant materials, optimized fluid dynamics for higher efficiencies and minimized noise levels. Digital electronics integration allows sensors and controllers to optimize motor performance and health monitoring. Some prototypes even use alternate working fluids like compressed air or renewable bio-fuels. Miniaturization potential may expand their use in consumer products. Overall, with constant innovations, axial piston motors will continue powering hydraulic systems across industries in decades to come. Their technological evolution also aligns well with trends toward electrification, automation, precision control and energy efficiency.

Get More Insights - Axial Piston Motors

Get This Report in Japanese Language - アキシャルピストンモーター

Get This Report in Korean Language - 축 피스톤 모터

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)