Why Choosing the Right Custom Hardware Manufacturer Will Make or Break Your Next Project

“The biggest risk is not the price — it’s choosing the wrong custom hardware manufacturer.”After helping 500+ global brands solve their toughest metal part challenges in the past 10 years, here’s what actually separates a reliable custom hardware manufacturer from the rest.What a True Custom Hardware Manufacturer Should Deliver

- Full Process In-House (No Subcontractor Surprises)

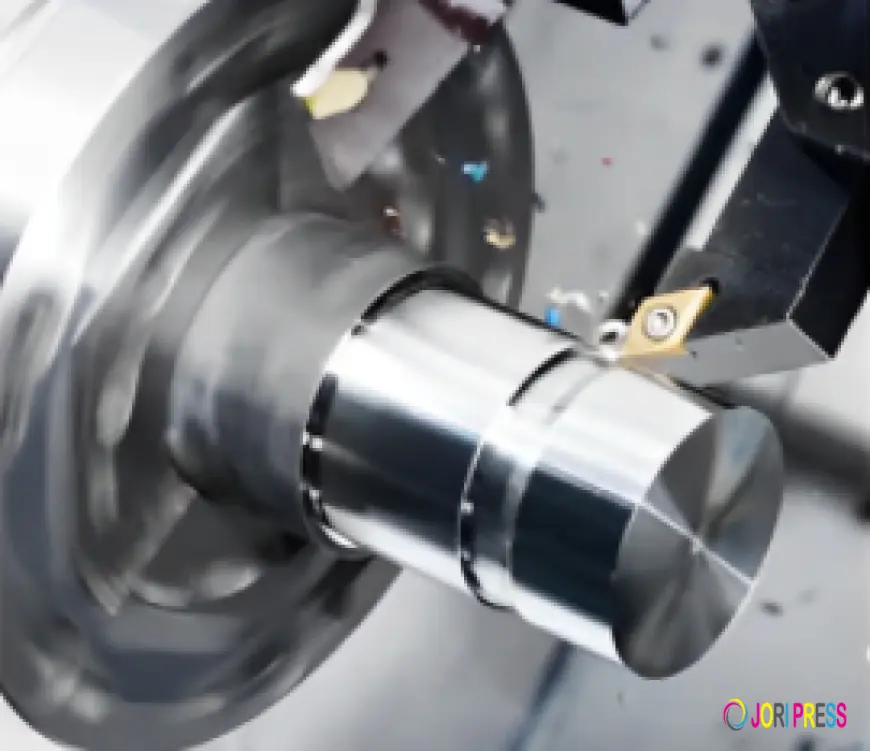

Real one-stop service means die casting, forging, sheet metal, CNC machining, and surface finishing (anodizing, electroplating, powder coating, Dacromet, etc.) are all under the same roof. Fewer middlemen = better quality control and faster lead times. - Proven Engineering Support from Day 1

You send a rough sketch or 3D file → we return a detailed DFM (Design for Manufacturability) report within 24-48 hours, pointing out cost-saving opportunities and potential failures before a single tool is made. - From 100 pcs Prototypes to 10 Million pcs Mass Production

Same factory, same team, same quality standard — whether you need rapid prototyping or high-volume fastener production. - Certifications & Traceability You Can Actually Trust

IATF 16949, ISO 9001, RoHS, REACH, and full material & process traceability for every batch.

- 10+ years focused only on custom metal hardware

- 30,000㎡ modern facility with 200+ skilled workers

- Served clients from USA, Germany, UK, Australia, Japan, and 30+ countries

- Specialty: aluminum/zinc die casting, hot & cold forging, precision sheet metal, CNC machining, standard & custom fasteners

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0