What Is Steel Fabrication? A Practical Guide for Melbourne Business

Learn what steel fabrication is, how the process works, and why it matters for Melbourne businesses. A practical guide for construction and industrial projects.

If you have ever asked, what is steel fabrication, you are likely planning a project and want clear answers. Whether you run a construction company in Dandenong, manage a warehouse in Truganina, or operate a manufacturing plant in the southeast suburbs, steel fabrication plays a direct role in how your project performs.

In simple terms, steel fabrication is the process of cutting, shaping, and assembling raw steel into finished products or structural components. It turns flat sheets, beams, and plates into staircases, brackets, frames, platforms, and engineered structures that businesses rely on every day.

Let us break it down in practical language so you can make informed decisions for your Melbourne business.

What Is Steel Fabrication in Practical Terms?

Steel fabrication transforms raw steel into usable parts through processes such as cutting, bending, welding, and finishing. It is different from steel manufacturing, which produces the raw material itself. Fabrication starts after the steel has already been made.

Think of it like this. A steel mill produces the raw material. A steel fabricator turns that material into something functional and specific to your project.

Steel fabrication commonly works with:

-

Mild steel for general construction and cost-effective projects

-

Stainless steel for corrosion resistance and hygiene-sensitive areas

-

Structural steel for load-bearing frames

-

Aluminium when weight reduction matters

For Melbourne businesses, fabricated steel supports commercial buildings, retail fit-outs, machinery platforms, transport infrastructure, and custom industrial equipment.

The Steel Fabrication Process Step by Step

Understanding the process helps you plan better and avoid delays.

Design and Engineering

Every job begins with drawings. Fabricators work from engineering plans or develop designs using 2D CAD and 3D CAD software. Accurate drawings reduce errors and prevent expensive rework.

For commercial and structural work in Victoria, compliance with Australian Standards such as AS and NZS requirements is part of responsible fabrication.

Cutting the Steel

Steel is cut into shape using different methods depending on thickness and precision requirements.

Common cutting methods include:

-

Laser cutting for high accuracy and clean edges

-

Plasma cutting for thicker materials

-

Saw cutting for structural sections

Precision at this stage affects how smoothly everything fits together during installation.

Forming and Shaping

Once cut, steel may need to be bent or rolled. Press braking shapes a flat sheet into brackets or channels. Rolling forms curved components. Turret punching creates holes or patterns in sheet metal quickly and consistently.

This stage is where flat material becomes three-dimensional.

Welding and Assembly

Welding joins individual parts into one structure. MIG welding and TIG welding are common techniques, depending on material and application.

Strong welds are not just about appearance. They affect safety, load capacity, and long-term durability.

Surface Finishing

Finishing protects steel and improves appearance. Options include:

-

Powder coating for durability and colour

-

Galvanising for corrosion protection

-

Sandblasting for surface preparation

In coastal areas of Melbourne, where moisture and salt can be present, finishing choices matter even more.

Where Steel Fabrication Is Used in Melbourne

Steel fabrication supports a wide range of industries across Victoria.

Construction and Commercial Projects

Builders rely on fabricated steel for:

-

Structural frames and beams

-

Staircases and balustrades

-

Columns and support structures

-

Custom brackets and connection plates

Accurate fabrication helps construction teams stay on schedule. When parts fit the first time, installers are not left improvising on-site.

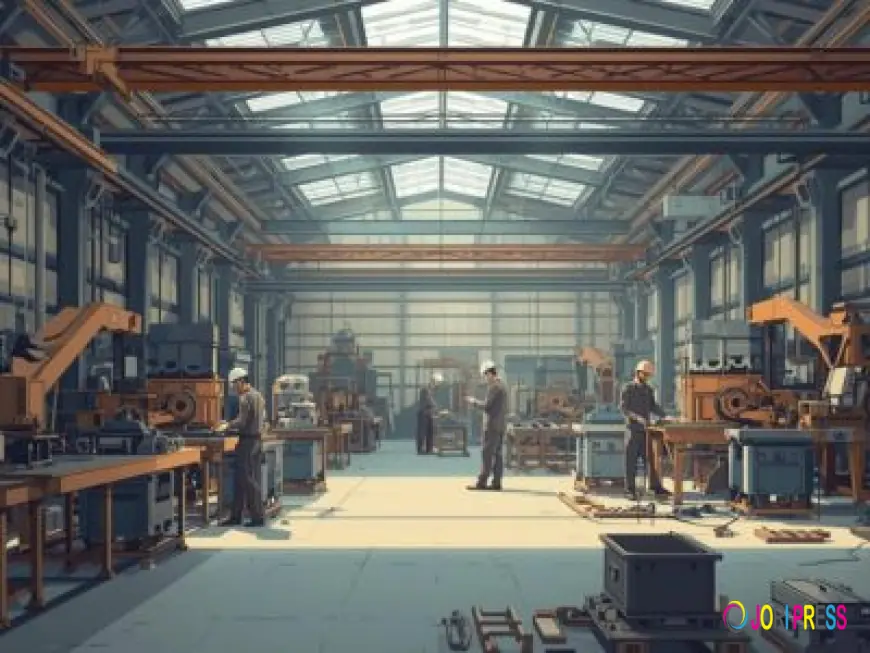

Industrial and Manufacturing

In factories and warehouses, fabricated steel is used for:

-

Machine bases

-

Equipment platforms

-

Safety guards

-

Conveyor systems

-

Mezzanine floors

For industrial operators, durability is key. Downtime costs money, so reliability matters.

Retail and Architectural Fit Outs

Fabricated steel is often hidden behind walls or featured as an architectural element. It supports shelving systems, display units, feature staircases, and structural supports for shopfronts.

The result needs to be strong, clean, and consistent.

Why Steel Fabrication Matters for Business Performance

For business owners, steel fabrication is not just about metal. It affects timelines, safety, and profitability.

High-quality fabrication can:

-

Reduce installation time

-

Improve structural reliability

-

Minimise rework

-

Extend the service life of assets

-

Support compliance with safety regulations

Poor fabrication, on the other hand, can cause delays, site modifications, and extra labour costs.

It is similar to ordering a custom suit. If it is measured properly, it fits well. If not, adjustments become expensive and frustrating.

Steel Fabrication vs Sheet Metal Fabrication

Many business owners use these terms interchangeably, but they are slightly different.

Steel fabrication often refers to heavier structural work such as beams, frames, and load-bearing components.

Sheet metal fabrication typically involves thinner materials used for panels, enclosures, ducting, and brackets.

Both processes may use laser cutting, bending, and welding, but the scale and application vary. Understanding the difference helps you approach the right specialist for your project.

Choosing the Right Steel Fabrication Partner in Melbourne

If you are investing in fabricated steel, experience and capability matter.

Here are practical things to look for:

-

Proven industry experience

-

Clear communication and realistic lead times

-

In-house cutting, forming, and welding capabilities

-

Quality control processes

-

Familiarity with Australian Standards

-

Ability to read and interpret engineering drawings

Local fabrication also supports faster turnaround and easier site coordination. When your fabricator is based in Melbourne, such as Swift Metal Fabrication, communication tends to be smoother and logistics simpler.

How Steel Fabrication Supports Melbourne’s Growth

Melbourne continues to expand with new commercial developments, infrastructure upgrades, and industrial growth corridors. Steel fabrication supports this expansion quietly in the background.

Every warehouse frame, stairwell, platform, and support bracket plays a role. Fabricated steel holds buildings together, supports heavy equipment, and allows businesses to operate safely.

Without it, construction and manufacturing would slow to a crawl.

Final Thoughts

So, what is steel fabrication? It is the process of transforming raw steel into practical, engineered components that keep businesses running. From structural beams to custom brackets, fabricated steel forms the backbone of construction, manufacturing, and commercial projects across Melbourne.

Understanding how steel fabrication works helps you plan better, budget wisely, and choose partners with confidence. When fabrication is done properly, projects run more smoothly, installations are cleaner, and long-term performance improves.

For Melbourne business owners, that clarity is not just helpful. It is smart business.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0