Ultimate Guide to Floor Marking Tape: Types, Uses, and Best Practices

Discover the ultimate guide to floor marking tape – explore its types, uses, and best practices to enhance workplace safety and efficiency.

In modern industrial and commercial facilities, floor marking tape plays a crucial role in ensuring safety, organization, and compliance with workplace standards. From warehouses and factories to retail stores and hospitals, these durable adhesive tapes help create visual cues that guide employees, visitors, and equipment traffic. Whether you are looking to improve workplace safety or streamline operational efficiency, understanding the different types, applications, and best practices for floor marking tape is essential.

What is Floor Marking Tape and Why is it Important?

Floor marking tape is a durable adhesive product designed to mark floors and communicate critical information visually. It is widely used in industries to:

-

Define walkways and pathways.

-

Highlight hazardous zones and safety areas.

-

Indicate storage and equipment placement zones.

-

Support compliance with OSHA and workplace safety regulations.

Unlike paint, floor marking tape is easy to install, cost-effective, and can be removed or replaced without disrupting operations. Its flexibility and durability make it a preferred choice for facilities that need clear, adaptable floor markings.

Types of Floor Marking Tape

Not all floor marking tapes are created equal. Choosing the right type depends on your facility’s environment, traffic levels, and safety requirements. Below are the most common types:

1. Vinyl Floor Marking Tape

-

Best for: Light to medium traffic areas.

-

Features: Flexible, easy to apply, and available in multiple colors.

-

Advantages: Affordable, suitable for temporary or semi-permanent use.

2. Heavy-Duty PVC Floor Tape

-

Best for: High-traffic industrial areas and warehouses.

-

Features: Thicker, abrasion-resistant, with strong adhesive backing.

-

Advantages: Long-lasting and capable of withstanding forklifts and heavy machinery.

3. Reflective and Glow-in-the-Dark Tape

-

Best for: Low-light or emergency exit pathways.

-

Features: Reflective coating or photoluminescent properties.

-

Advantages: Improves visibility in dark conditions, enhancing safety compliance.

4. Anti-Slip Floor Marking Tape

-

Best for: Ramps, stairs, and wet or oily environments.

-

Features: Gritty, non-slip surface for improved traction.

-

Advantages: Reduces the risk of slips and falls in hazardous areas.

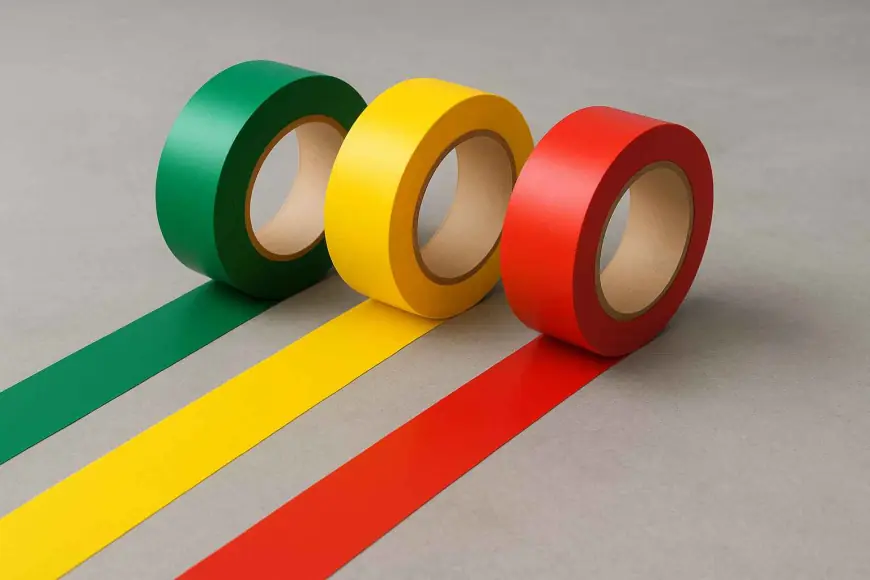

5. Color-Coded Safety Tape

-

Best for: Visual management systems like 5S or Lean Manufacturing.

-

Features: Available in standardized colors (e.g., yellow for caution, red for fire hazards).

-

Advantages: Helps create clear visual communication for safety and organization.

Common Uses of Floor Marking Tape

The versatility of floor marking tape makes it indispensable across industries. Some of the most common applications include:

1. Safety and Hazard Identification

Clearly marking hazardous zones reduces workplace accidents. Bright-colored and reflective tapes draw attention to dangerous machinery, restricted areas, and tripping hazards.

2. Workflow and Traffic Control

Marking walkways and equipment lanes keeps pedestrian and forklift traffic organized, reducing congestion and preventing accidents.

3. 5S and Lean Manufacturing Implementation

In Lean facilities, floor tape helps organize tools, materials, and workstations, improving operational efficiency and reducing downtime.

4. Emergency Evacuation Guidance

Glow-in-the-dark and reflective tapes mark exit paths to guide employees during power outages or emergencies.

5. Storage and Inventory Management

Outlining designated areas for pallets, racks, and equipment with color-coded tape ensures optimal use of floor space and quick location of materials.

Best Practices for Using Floor Marking Tape

To maximize durability and effectiveness, follow these best practices when applying floor marking tape:

1. Choose the Right Tape for Your Environment

Consider factors such as traffic load, floor type, and exposure to chemicals or moisture before selecting a tape.

2. Proper Surface Preparation

-

Clean and dry the floor thoroughly to remove dust, grease, or debris.

-

Ensure the surface is smooth and free of cracks for optimal adhesion.

3. Use Consistent Color Codes

Implement a standardized color-coding system for clarity. For example:

-

Yellow: Aisles and pathways.

-

Red: Fire equipment zones.

-

Blue: Raw material storage.

-

Green: Finished goods.

4. Apply Tape with Precision

Use a tape applicator for straight, consistent lines. Avoid stretching the tape during application, as it may lead to peeling or lifting.

5. Regular Maintenance and Inspection

Check tape regularly for wear and tear. Replace damaged sections immediately to maintain visibility and safety.

Benefits of Using Floor Marking Tape Over Paint

While painted lines are a traditional option, floor marking tape offers significant advantages:

-

Easy to Install and Replace: No downtime or curing required.

-

Highly Durable: Designed to withstand heavy foot and vehicle traffic.

-

Versatile and Flexible: Available in a variety of colors, widths, and patterns.

-

Cost-Effective: Minimal labor costs compared to repainting.

Compliance and Safety Standards

Many industries are required to comply with OSHA and ANSI standards regarding floor marking. Using high-quality floor marking tape ensures compliance while maintaining workplace safety and efficiency. Consult local regulations to select the right tape width, colors, and placement.

Conclusion: Enhance Safety and Efficiency with the Right Floor Marking Tape

Investing in the right floor marking tape not only improves safety but also streamlines operations and ensures compliance with workplace standards. Whether you manage a warehouse, factory, or commercial facility, choosing the right tape and following best practices can make a measurable difference in productivity and safety culture.

If you’re looking for high-quality floor marking tape or other packaging and safety solutions, partnering with professional packaging companies in uae can help you source the most durable and cost-effective products for your facility. Take action today to create a safer, more organized workplace with the right visual communication tools.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0