Six Sigma: A Detailed Roadmap to Success in 2025

Discover the profound benefits of Six Sigma in 2025, a data-guided method for process enhancement. This insightful guide, updated on July 31, 2025 at 12:04 PM IST, outlines the DMAIC approach, expertise levels, and its impact on minimizing defects and boosting productivity. Perfect for professionals and organizations aiming to elevate performance.

Exploring the Foundations of Six Sigma

Six Sigma has transformed business landscapes, with Motorola attaining 99.99966% defect-free quality and General Electric achieving $12 billion in savings over five years. Derived from the Greek “Sigma” for standard deviation, it defines a process where variation is so slight that the specification limit is six standard deviations from the mean. This data-reliant technique detects and removes defects, inefficiencies, and errors, improving the reliability, pace, and scalability of processes, products, and services. It serves as a philosophy for relentless improvement, a benchmark for performance evaluation, and a structured method using DMAIC to resolve significant business challenges.

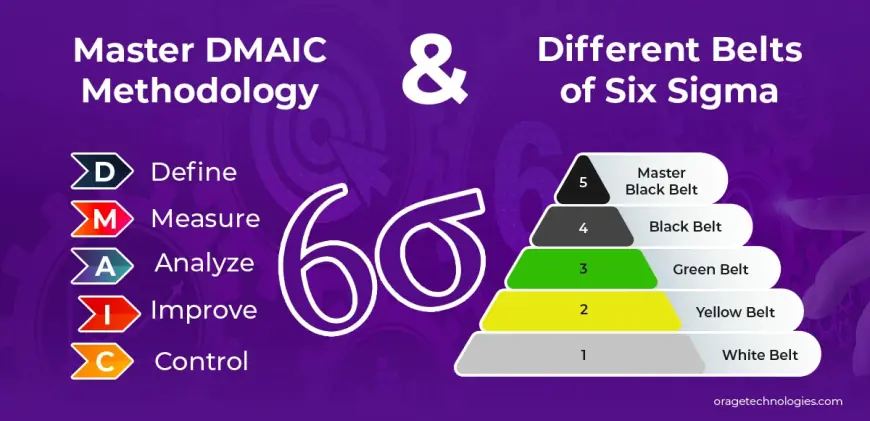

Navigating the DMAIC Structure of Six Sigma

Define Phase: Setting Clear Objectives

The Define phase launches the Six Sigma process by precisely defining the problem and aligning it with business goals. As Charles Kettering famously stated, “A problem well stated is a problem half solved.” This stage involves determining the project’s purpose, its importance, success measures, key participants, and timelines. Key activities include crafting SMART problem and goal statements, developing a project charter with metrics, benefits, scope, milestones, and signatures, and building a SIPOC diagram to map suppliers, inputs, processes, outputs, and customers for a comprehensive process overview.

Measure Phase: Quantifying the Current Performance

With the problem defined, the Measure phase assesses its scope through data analysis. The objective is to establish a baseline by measuring existing performance. This includes creating a data collection plan, mapping the process to identify inefficiencies, conducting measurement analysis for precision and reproducibility, evaluating performance output (Y) against standards and defect rates, and assessing process capability using metrics such as Upper Specification Limit (USL), defect rate, yield, and Sigma level.

Analyze Phase: Digging Into Root Causes

The Analyze phase is a vital component of Six Sigma, aiming to uncover the root causes (X) of issues, where Y = f(X), rather than addressing surface-level symptoms. This stage involves brainstorming potential causes, organizing them with a Cause-Effect or Fishbone diagram, selecting probable causes, designing a data collection plan with testing protocols, and validating key causes through hypothesis testing with tools like bar charts, Pareto charts, histograms, or box plots.

Improve Phase: Implementing Practical Solutions

The Improve phase translates root causes into effective solutions to enhance output (Y). It includes generating ideas using techniques like Six Thinking Hats or expert insights, assessing options with tools such as Effort-Impact Matrix or Design of Experiments (DOE), choosing optimal solutions with Failure Modes and Effects Analysis (FMEA), applying mistake-proofing (Poka-Yoke) at prevention, facilitation, or detection levels, and deploying solutions through pilot testing and a full-scale plan with communication and training.

Control Phase: Securing Sustained Results

The Control phase ensures the durability of Six Sigma improvements. It involves developing a control plan with performance targets and monitoring strategies, utilizing Statistical Process Control (SPC) charts to manage variations, revising procedures, training teams, transferring ownership, and verifying financial gains like cost savings or waste reduction to confirm goal attainment.

Critical Leadership Roles in Six Sigma Projects

Leadership is essential for Six Sigma effectiveness, with executives and champions nurturing a culture of continuous progress. Leaders including CEOs, CFOs, COOs, CIOs, Vice Presidents, and Directors align projects with strategic aims, establish selection criteria, approve initiatives, designate champions, and provide resources. Champions manage project execution, ensuring organizational backing and resource support.

Levels of Competency in Six Sigma

White Belt: The Beginning Stage

The White Belt introduces Six Sigma essentials, covering concepts, quality focus, and process understanding. Designed to awaken interest, it prepares individuals to support local activities and assist small teams with basic insights.

Yellow Belt: Acquiring Essential Skills

Yellow Belts build expertise with DMAIC training, learning process mapping, Voice of Customer, and root cause analysis. They lead minor projects and support larger efforts under Green or Black Belt leadership, enhancing departmental solutions.

Green Belt: Guiding with Data-Driven Insights

Green Belts lead part-time DMAIC projects, mastering all phases, statistical techniques, and practical problem-solving. They drive moderate-scale improvements while managing daily duties, enhancing processes within their scope.

Black Belt: Leading Complex Initiatives

Black Belts are full-time Six Sigma professionals, managing cross-functional projects with advanced skills in statistics, process evaluation, hypothesis testing, and Design of Experiments (DOE). They oversee significant projects, mentor Green Belts, and offer technical guidance.

Master Black Belt: Directing Strategic Vision

Master Black Belts, the top Six Sigma authorities, excel in statistical analysis, change leadership, coaching, and training design. They mentor Black Belts, influence project strategies, and uphold program standards, often serving as internal or external advisors.

Conclusion: The Lasting Legacy of Six Sigma

Six Sigma, underpinned by its DMAIC framework and tiered expertise, delivers a strong platform for process refinement across sectors. By reducing defects, increasing efficiency, and cultivating leadership, it provides substantial financial and operational advantages. With proficient experts at every level, it guarantees ongoing improvement and innovation.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0