Mastering DMAIC and Six Sigma Belts for Process Excellence

Unlock the power of Six Sigma with a deep dive into the DMAIC methodology and belt hierarchy. Learn how Yellow, Green, Black, and Master Black Belts drive process excellence.

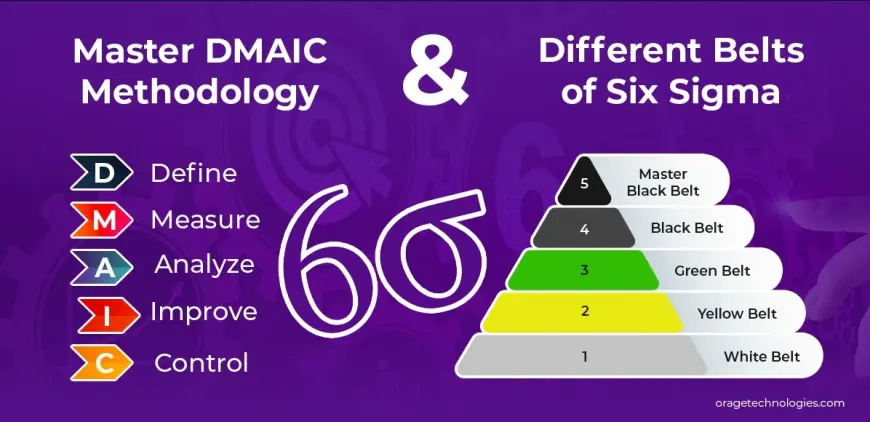

Six Sigma is a transformative approach for organisations committed to operational excellence, utilising data-driven methods to reduce defects and enhance efficiency. At the core of Six Sigma is the DMAIC approach, a defined process for improvement, and a multiple-tier level of expertise called Six Sigma belts. This blog post explores a new approach to learning about DMAIC and understanding Six Sigma belts, addressing commonly asked questions and clarifying expectations and key takeaways for action. Let’s talk about how Six Sigma allows organisations to achieve quality and performance that is truly world-class.

What Is Six Sigma and Why Is It Important?

Six Sigma is a quality improvement methodology developed by Motorola in the 1980s. Six Sigma focuses on defect identification and removal from processes, helping organisations deliver consistent, high-quality products and services based on relevant statistical tools using a structured and disciplined methodology. Why should you care? In a competitive environment, businesses that are efficient and customer-focused have an advantage. Six Sigma provides a framework to help organisations achieve the highest possible quality, which is defined as a maximum of 3.4 defects per million opportunities, which is a pretty good number! Six Sigma can improve indirect and direct costs, customer loyalty, and organisational performance.

On the practical side, Six Sigma methodologies are designed to be structured and consistent (e.g. DMAIC), making it easy for organisations to use. The belt system reinforces a variety of people, at a variety of levels, providing involvement in process improvement. Six Sigma is a very flexible program for organisations of all different sizes.

What is the DMAIC methodology, and how does it work?

DMAIC stands for Define, Measure, Analyse, Improve, Control, and is a structure consisting of five phases of Six Sigma projects. Each phase has a specific purpose for helping the project team resolve the inefficiencies of the process being measured. The first phase is the Define phase, where the problem is presented, goals for the project are established, and the client's requirements are defined. This is followed by the Measure phase, in which data is gathered to establish a baseline of how the process is performing now. Then, in the Analyse phase, project teams will utilise a variety of statistical tools to analyse the data collected to identify the source of defects. Next is the Improve phase, where the project team will develop and implement solutions to the defects. Finally comes the Control Phase, where a plan is developed to monitor and control the improvements and ensure that the improvements are standardised.

For instance, a product manufacturing company may use the DMAIC methodology to track product defects, as its product defect rate is becoming an issue. The project team would define the problem of high defect rates in a product line (Define phase), measure the current process rates of defect (Measure phase), analyze the data to identify the defects (Analyze phase), improve the current work processes to improve the quality of the product (Improve phase), and finally control the outcome by establishing controls such as maintenance schedules (Control phase). As a result, the product manufacturing company achieved substantial improvements in product quality. DMAIC provides a clear, repeatable procedure for achieving success with Six Sigma projects.

What Are the Six Different Six Sigma Belts and Their Responsibilities?

Six Sigma uses a belt system to categorise expertise, much like martial arts. The belts represent expertise, role and responsibility in Six Sigma process improvement projects. Here is how I will categorise the six main belts:

White Belt: White Belts are at the most basic level of understanding the principles of Six Sigma.. A White Belt would help on projects with tasks such as data collection and process mapping, typically under the direction of an upper belt. Once assigned tasks are completed, their role would cease.

Yellow Belt: Yellow Belts have basic knowledge of Six Sigma tools and can assist in project work. They are expected to help with problem-solving and data analysis activities as part of the overall project team.

Green Belt: Green Belts have analytical skills and an extensive understanding of Six Sigma principles to be able to lead smaller Six Sigma projects and assist Black Belts with larger projects. Green Belts will apply DMAIC when working on a Six Sigma process improvement project to solve a specific process problem or issue.

Black Belt: Black Belts are subject matter and process improvement experts who can lead more complex Six Sigma projects. Black belts will mentor Green Belts, use a variety of advanced statistical tools and provide system and process improvements with significant impacts to the organisation's bottom line.

Master Black Belt: Master Black Belts are strategic leaders, responsible for the oversight of multiple Six Sigma process improvement projects; training and development of Six Sigma practitioners; and ensuring Six Sigma projects align with an organisation's strategic goals and objectives.

Each belt level progresses from the previous one, and overall, a hierarchy of competence is created. Therefore, if organisations employ professionals at the right belt level for initiatives and projects, implementation of Six Sigma is likely to be effective.

How Does DMAIC Work with a Six Sigma Belt?

The DMAIC process is a method used across Six Sigma belts, whether the project is a DMAIC project led by the Green Belt or the project reviewed by a Black Belt using a DMAIC approach to align outcomes with organisational objectives. The Master Black Belt offers strategic design and planning for DMAIC projects, ensuring that they connect with long-term strategic outcomes, while White Belts and Yellow Belts provide data collection and emergency documentation, allowing the Green, Black, or Master Black Belt to focus on analysis for improvements.

The use of the Six Sigma belt roles helps ensure projects using the DMAIC process remain both tactical and strategic. The link between the DMAIC process and structured planning through the use of Six Sigma roles offers a high level of response through the use of belts as project roles, allowing organisations to minimise waste and improve efficiency. You could see that the DMAIC process is very beneficial when compared with a Six Sigma belt structure and expertise.

What are the Advantages of utilising Six Sigma and DMAIC?

There are many advantages to utilising Six Sigma and DMAIC. First, organisations can achieve massive cost savings through defect and waste improvement. For example, if a healthcare provider used DMAIC, they may reduce the waiting time for a patient and increase efficiency and customer satisfaction. Second, Six Sigma will lead to improved customer satisfaction, as the organisation will consistently deliver a higher level of quality. Third, Six Sigma helps to establish the approach and culture of continuous improvement (or continual improvement), enabling employees to become immersed in problem solving - because they are now empowered to proactively identify and tackle problems.

Finally, because Six Sigma is data-driven, organisations can approach a problem with demonstrated facts instead of assumptions. This enables organisations to face large, complex problems with confidence. When organisations train employees at each belt level, they empower employees to take ownership of the improvement process and develop an internal workforce that is able to drive change that is measurable and sustainable over time.

Six Sigma Training: How to Get Started

To start Six Sigma training, it is important to understand your objectives and select the appropriate belt level. A White or Yellow Belt training provides a basic understanding of Six Sigma and prepares you for further training. White or Yellow Belt courses are conducted by many suppliers; they are usually available online and led by certified providers. You will learn basic definitions of Six Sigma concepts, process mapping, and data collection. If you are looking to take charge of Six Sigma projects, you need to get a Green Belt or Black Belt training, which will give you a complete, valid understanding of DMAIC, process improvements, and statistical tools to analyse and use data.

You can find training by searching reputable providers. The American Society for Quality (ASQ) and the International Association for Six Sigma Certification (IASSC) are both reliable. There are also reputable companies offering Six Sigma online classes, either self-paced or instructor-led. Once you have completed all the training, if you take the certification exam(s), you will get an extra value from your training, and you can begin to sell your expertise and gain credibility. Becoming trained and certified in Six Sigma will give you the tools to drive change and improvements in any organisation.

What Problems Will Arise When You Start Trying to Implement Six Sigma?

Even though Six Sigma is incredibly powerful, it is not without its challenges. First, resistance to change is a natural reaction, and many employees are simply not ready to accept new processes; therefore, it is important to state the benefits of Six Sigma in a clear manner and to gain the involvement of team members at the beginning of the process. Second, data collection, once again a very time-consuming process, may be especially burdensome for organisations with little to no data infrastructure. During this latter phase of data collection and analysis, an organisation may be forced to either invest in data systems or train Yellow Belts to help collect the data for the organisation.

The third and most important part of achieving Six Sigma involves keeping the momentum of the organisation's transformation after the initial improvements have surpassed expectations, but it requires leadership at the Master Black Belt level to ensure that the projects remain within the Six Sigma framework. Ultimately, we must identify and be prepared for these potential roadblocks so we can take action and leverage Six Sigma for the organisation we work for.

How Does Six Sigma Work Across Industries?

The applications of Six Sigma are quite extensive, which is why Six Sigma can improve performance in practically any industry. For instance, in manufacturing, Six Sigma can help organisations reduce defects in their production lines; such is the case with leading organisations we may know today, like General Electric.

In healthcare, Six Sigma can simplify the processes involved in patient care and development as it pertains to the patient's experience, patient outcomes, and cost reduction. For example, a hospital could use DMAIC to mitigate medication errors.

In the service industry, such as the financial services, hospitality, or food services industry, Six Sigma can help improvements in customer experience, e.g., optimising workflows.

In addition, with Six Sigma being applicable in practically every field, it can also be readily applied in New Technology areas like software development or IT service delivery.

More generally, the ubiquitous nature of Six Sigma is enabled by the inventiveness or development of the principles of Six Sigma, including statements such as data-driven development or decision making, and problem-solving processes, along with effectiveness and efficiency-related challenges that continuous improvement processes can potentially resolve.

Frequently Asked Questions About Six Sigma and DMAIC

Q. How Long Does It Take to Earn a Six Sigma Belt?

The time varies by belt level. White and Yellow Belt certifications often take a few days of training. Green Belt programs typically require one to two weeks, while Black Belt training can span several weeks with project experience. Master Black Belt certification may take months, including mentoring and strategic project work. Online courses offer flexibility, but hands-on projects are key.

Q. Is Six Sigma Only for Manufacturing?

No, Six Sigma applies to diverse industries, including healthcare, finance, and IT. For example, hospitals use it to reduce patient wait times, and banks apply it to streamline loan processing. Its principles are universal, focusing on process improvement and defect reduction.

Q. Can Small Businesses Use Six Sigma?

Absolutely. Small businesses benefit from Six Sigma by improving efficiency and reducing waste. Even with limited resources, Yellow or Green Belt projects can yield significant savings. The key is tailoring projects to the business’s scale and needs.

Q. What Tools Are Essential for DMAIC?

DMAIC relies on tools like process maps, control charts, fishbone diagrams, and statistical software (e.g., Minitab). These tools help analyse data, identify root causes, and monitor results. Training ensures teams use them effectively.

Conclusion

Mastering the DMAIC methodology and understanding Six Sigma belts empower professionals to drive meaningful change. From White Belts supporting projects to Master Black Belts shaping strategy, each role contributes to operational excellence. By embracing Six Sigma’s data-driven approach, organisations unlock efficiency, quality, and profitability. Whether you’re starting with a White Belt or aiming for a Master Black Belt, the journey begins with a commitment to continuous improvement. Ready to transform your processes? Dive into Six Sigma and discover its potential.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0