Sheet Metal Fabrication Process: A Complete Guide to Precision Engineering

The sheet metal fabrication process is a core manufacturing technique that transforms flat metal sheets into various functional components and structures. This process is widely used in industries such as automotive, aerospace, construction, electronics, and heavy machinery. With advancements in technology and precision tools, modern sheet metal fabrication combines traditional craftsmanship with cutting-edge machinery to deliver high-quality, durable, and customized products. Companies like Samarth Sharp Edge specialize in offering reliable and cost-effective fabrication solutions that meet global quality standards.

What is the Sheet Metal Fabrication Process?

The sheet metal fabrication process involves cutting, bending, and assembling metal sheets into desired shapes and products. Materials like stainless steel, aluminum, brass, copper, and mild steel are commonly used depending on the application. The process begins with a detailed design, usually created through CAD (Computer-Aided Design) software, and ends with the finished product, which may undergo surface finishing for aesthetics and corrosion resistance. This process is valued for its ability to produce complex shapes with high strength-to-weight ratios while maintaining cost efficiency.

Key Steps in the Sheet Metal Fabrication Process

While the fabrication sequence may vary depending on the project, most sheet metal fabrication follows these essential stages:

1. Design and Planning

The process starts with precise engineering designs. CAD models are prepared to ensure accurate dimensions, tolerances, and assembly details. This stage also involves selecting the right metal type, thickness, and finishing requirements based on the intended application.

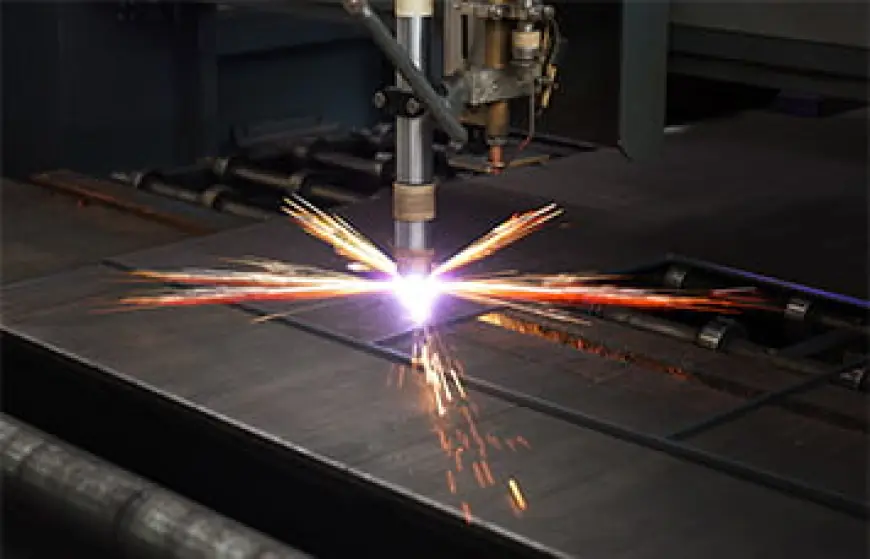

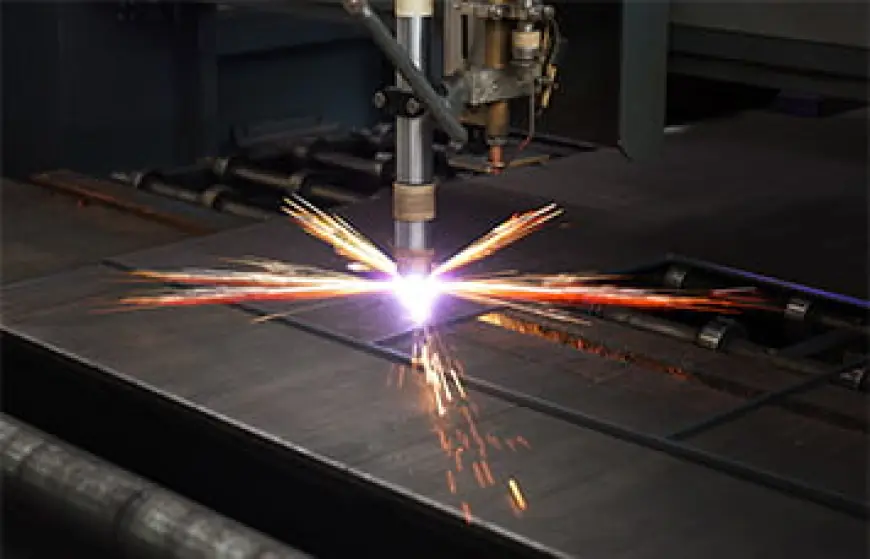

2. Cutting

Cutting is one of the most important stages in the sheet metal fabrication process. Modern methods such as laser cutting, plasma cutting, and water jet cutting allow for exceptional accuracy and minimal material wastage. For thicker or more specialized materials, mechanical shearing or CNC punching may be used.

3. Bending and Forming

Once cut, the sheets are bent using press brakes or roll forming machines to achieve the required angles and curves. This step requires precise force application to prevent cracks, distortions, or uneven bends.

4. Assembling and Joining

Fabricated parts are joined using welding, riveting, or adhesive bonding techniques. MIG, TIG, and spot welding are commonly used for strong and durable joints. In some cases, threaded fasteners are added for parts that need disassembly.

5. Surface Finishing

To enhance durability and appearance, sheet metal products undergo finishing processes like powder coating, painting, galvanizing, or anodizing. This protects against corrosion and gives the final product a polished look.

6. Quality Inspection

Before delivery, each product is inspected for dimensional accuracy, structural integrity, and surface quality. Advanced measurement tools and testing methods ensure that the fabricated components meet exact specifications.

Materials Used in Sheet Metal Fabrication

Choosing the right material is critical to the success of the sheet metal fabrication process. Some of the most popular materials include:

- Stainless Steel – Highly resistant to corrosion, ideal for food processing, medical, and marine industries.

- Aluminum – Lightweight, corrosion-resistant, and easy to shape, perfect for aerospace and automotive applications.

- Mild Steel – Strong and cost-effective, widely used in construction and heavy machinery.

- Brass & Copper – Known for conductivity and decorative appeal, used in electrical and architectural projects.

Each material has unique properties that influence fabrication techniques, costs, and performance.

Applications of the Sheet Metal Fabrication Process

The versatility of the sheet metal fabrication process makes it suitable for a wide range of industries, including:

- Automotive Parts – Body panels, chassis components, brackets, and exhaust systems.

- Aerospace Components – Lightweight yet strong structural parts and engine housings.

- Construction Industry – Roofing, ductwork, and structural frameworks.

- Electronics – Enclosures, panels, and heat sinks for various devices.

- Industrial Equipment – Machine guards, conveyor systems, and storage units.

With custom fabrication capabilities, products can be tailored to specific operational and environmental needs.

Advantages of the Sheet Metal Fabrication Process

Investing in professional sheet metal fabrication offers multiple benefits:

- High Strength and Durability – Products are built to withstand extreme conditions.

- Cost Efficiency – Reduced waste and mass production capabilities lower overall costs.

- Design Flexibility – Complex shapes and intricate details are achievable.

- Scalability – Ideal for both small-batch and large-scale production runs.

- Sustainability – Most metals used are recyclable, making the process environmentally friendly.

Modern Trends in Sheet Metal Fabrication

The sheet metal fabrication process has evolved significantly with technology integration. CNC (Computer Numerical Control) machines have revolutionized cutting and bending by enabling extreme precision and repeatability. Laser cutting systems allow for intricate designs with smooth edges, while automation in welding and assembly reduces production time. Additionally, Industry 4.0 and IoT-enabled monitoring systems improve efficiency, quality control, and predictive maintenance.

Why Choose Samarth Sharp Edge for Sheet Metal Fabrication

Samarth Sharp Edge is a trusted name in precision engineering and fabrication services. Here’s why they stand out:

- State-of-the-Art Machinery – Advanced laser cutters, CNC bending machines, and welding equipment ensure accuracy and consistency.

- Expert Workforce – Skilled technicians with years of hands-on fabrication experience.

- Custom Solutions – Tailored fabrication based on client requirements and industry standards.

- Quality Commitment – Strict inspection protocols and adherence to ISO standards.

- On-Time Delivery – Efficient project management to meet deadlines without compromising quality.

Whether you need one-off prototypes or high-volume production, Samarth Sharp Edge delivers excellence at every stage of the sheet metal fabrication process.

Tips for Optimizing Your Sheet Metal Fabrication Project

If you’re planning a fabrication project, consider the following:

- Engage Early with the Fabricator – Early consultation ensures design feasibility and cost efficiency.

- Choose the Right Material – Match the material properties to the product’s end use.

- Simplify the Design – Reducing complexity can lower costs without affecting performance.

- Consider Finishing Needs – Protective coatings and finishes extend product life.

- Plan for Scalability – Ensure the design can be replicated for future demand.

By applying these tips, you can achieve the perfect balance between functionality, aesthetics, and cost.

Conclusion

The sheet metal fabrication process is a backbone of modern manufacturing, offering unmatched flexibility, strength, and customization. From concept to completion, every stage requires precision, the right materials, and skilled execution. As industries demand higher performance and more intricate designs, the role of advanced fabrication technology becomes even more vital.

With expertise, cutting-edge tools, and a strong commitment to quality, Samarth Sharp Edge ensures that every fabricated component meets the highest standards. Whether it’s a small prototype or a large-scale production run, their team is equipped to bring your vision to life with accuracy and efficiency.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0