Precision in Motion: How Thermocouple Manufacturers Power the World of Industrial Automation

Discover how thermocouple manufacturers drive accuracy, reliability, and efficiency across industrial automation systems. Learn how advanced temperature-sensing technologies enhance performance in modern industrial environments.

Industrial automation is a quiet revolution at the core of contemporary industries. Production lines function with clockwork accuracy, systems communicate flawlessly, and machines perform in perfect synchronicity. This technological symphony is made up of innumerable parts that cooperate to guarantee efficiency, safety, and consistency. Manufacturers of thermocouples are essential among them.

One of the most important aspects of any industrial environment is temperature regulation. Whether it's a steel furnace, a chemical reactor, or a food processing line, maintaining precise heat conditions guarantees cost effectiveness, quality, and safety. And that's exactly what thermocouples and the professionals who manufacture them are for.

Comprehending Thermocouples: The Foundation of Temperature Monitoring

Fundamentally, a thermocouple is a straightforward but effective instrument. It generates a voltage that is proportional to temperature by joining two different metal wires at one end. When properly evaluated, this voltage yields accurate and trustworthy real-time temperature readings.

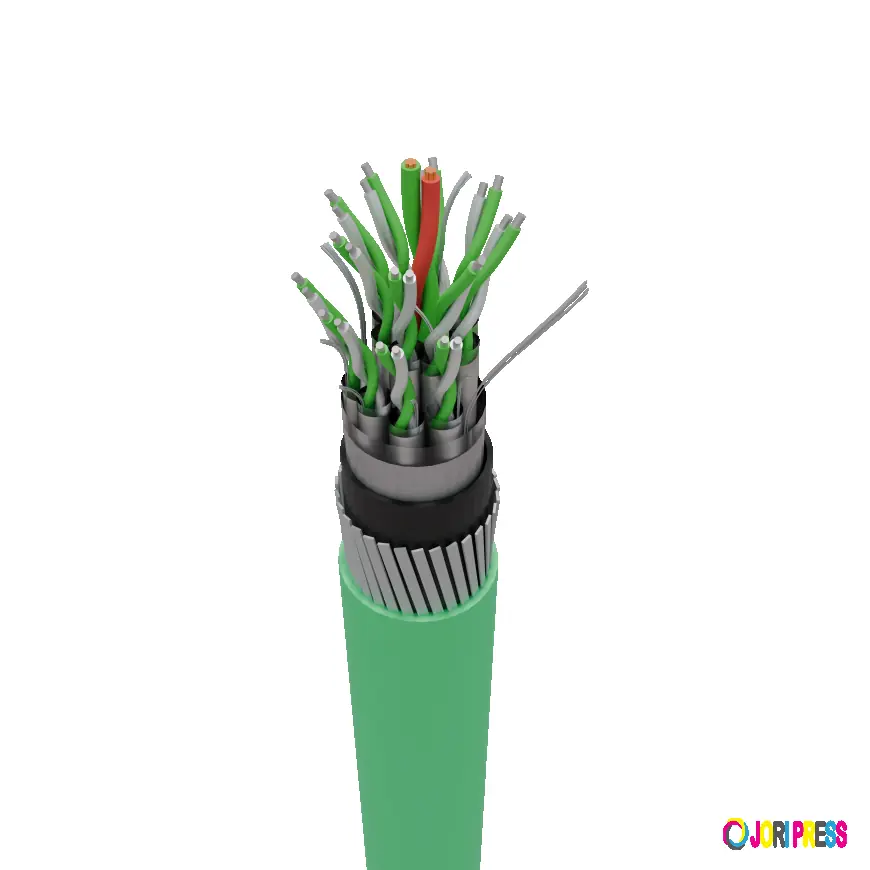

Nevertheless, the quality of a thermocouple's cable and wire determines how well it performs. These parts are painstakingly designed to withstand mechanical strain, high temperatures, and electromagnetic interference while preserving accurate signal transmission. To ensure that their sensors function flawlessly under the most demanding industrial settings, thermocouple producers make significant investments in materials research and engineering.

The Crucial Link Between Thermocouple Manufacturers and Automation Systems

Industrial automation thrives on data — and temperature is one of the most vital data points.Thermocouple manufacturers bridge the gap between physical processes and digital systems by supplying the tools that translate heat into actionable intelligence.

Modern automation relies on accurate temperature readings to trigger control responses, maintain process stability, and ensure product uniformity. For example, in a steel plant, automated systems must know exactly when to adjust furnace temperatures. Without dependable thermocouple feedback, such systems would falter, leading to inefficiencies or costly defects.

Manufacturers, therefore, aren’t just suppliers — they are partners in automation, providing the precision instruments that keep smart factories running efficiently.

Engineering Excellence: Materials, Design, and Manufacturing Precision

Each thermocouple starts with premium materials and careful design. From the intense heat of metal foundries to the cryogenic cold of space applications, manufacturers carefully choose alloys that can survive particular conditions.

Performance is mostly dependent on the thermocouple wire itself. It needs to be resistant to mechanical wear, corrosion, and oxidation. Similar to this, the thermocouple cable, which is frequently insulated and shielded, maintains signal integrity by making sure that there is no noise or distortion in the data being transferred. Manufacturers provide stability even in the most severe industrial settings by using accurate building methods and cutting-edge insulating materials.

Leading thermocouple manufacturers stand out for their commitment to quality control as well as their technological know-how. Before being delivered to the final user, each component is put through a rigorous calibration and testing process.

Innovation and Customization: Meeting the Demands of Modern Industry

Every industry has different needs when it comes to measuring temperature. While a petrochemical refinery requires robust sensors that can survive tremendous heat and corrosive gases, a pharmaceutical plant requires sterile, precise equipment.

Manufacturers of thermocouples provide specially designed solutions in recognition of this variability. Customization has been a feature of contemporary manufacturing, ranging from specially insulated thermocouple cables to specialty thermocouple wires made for certain temperature ranges.

Furthermore, advancement is fueled by innovation. Thermocouples are being incorporated into Internet of Things (IoT) platforms and wireless monitoring systems as a result of automation advancements, allowing for remote diagnostics, predictive maintenance, and more intelligent process control. Industry transitions to a more connected, efficient future are facilitated by manufacturers who adopt these innovations.

Quality Assurance: Building Trust Through Precision

In the context of industrial automation, dependability cannot be compromised. A single inaccurate reading has the potential to harm equipment, interfere with productivity, or jeopardize safety. Therefore, in order to remove any margin of error, thermocouple producers employ strict quality assurance standards.

Sustainability and the Green Revolution in Manufacturing

Manufacturers of thermocouples are rethinking their procedures in the age of sustainability in order to lessen their influence on the environment. In order to reduce waste, they are procuring environmentally friendly materials, increasing production energy efficiency, and developing thermocouples that last longer.

Moreover, thermocouples indirectly support sustainability by assisting enterprises in maintaining ideal temperature management. Emissions are decreased, energy waste is avoided, and resource efficiency is guaranteed by precise temperature management. Thermocouples contribute quietly but significantly to the development of a more environmentally friendly industrial ecosystem, whether it is through maintaining exact heat levels in the glassmaking process or regulating kiln temperatures in the cement production process.

The Global Impact: How Thermocouple Manufacturers Shape Industry 4.0

As Industry 4.0 progresses, industrial efficiency has been redefined through the integration of sensors, automation, and data analytics. Leading the way in this change are thermocouple manufacturers.

Their products supply vital temperature data to intelligent systems that make real-time adjustments on their own. Smart thermocouple cables with diagnostics built in have made it possible for industries to remotely check on the functionality and condition of their sensors. This data is used by predictive maintenance algorithms to avoid downtime, which saves money and time.

Thermocouples are the unseen links that link digital intelligence and physical processes in anything from digital twins that mimic production lines to robotics and AI-driven control systems.

The Future: Precision, Connectivity, and Continuous Evolution

The production of thermocouples will undoubtedly become more digital in the future. Manufacturers are pushing the limits of what's feasible as sectors demand quicker, more intelligent, and more sustainable solutions.

Even greater accuracy and durability are promised by emerging technologies like sophisticated alloys and nanomaterials. In the meantime, temperature control is being redefined by the combination of thermocouples and AI-powered monitoring systems. To further improve automation dependability, manufacturers are also investigating self-calibrating thermocouples, which make adjustments automatically in response to operational data.

Working together will be essential in the upcoming years. Manufacturers of thermocouples will keep collaborating with automation engineers, Internet of Things developers, and industrial designers to produce temperature sensing systems that are not only useful but revolutionary.

Conclusion: The Unsung Heroes of Industrial Precision

Although robotics, artificial intelligence, and software are frequently highlighted in automation, precision measurement is the real basis, and thermocouple makers are the keepers of that precision. They guarantee that the ideal thermal conditions are met for each weld, pour, and reaction.

They have emerged as the unsung heroes of industrial automation thanks to their inventiveness, excellence, and flexibility. Their proficiency in designing dependable thermocouple wire and cable systems guarantees the safe, effective, and sustainable operation of enterprises all over the world.

One thing is certain as technology advances: thermocouple producers will keep igniting the engines of advancement, one degree at a time.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0