Polyacrylamide Market Trends: Municipal Sludge, Industrial Effluent, and Tailings Management (2025–2034)

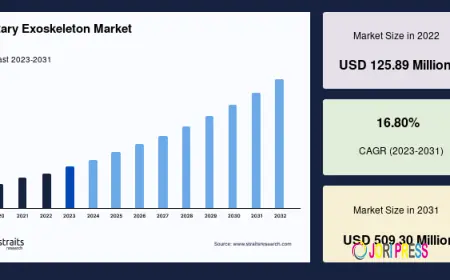

The Global Polyacrylamide Market was valued at $ 7.49 billion in 2025 and is projected to reach $ 16.03 billion by 2034, growing at a CAGR of 8.83%.

The polyacrylamide market is entering a high-impact decade as water-intensive industries, municipalities, and resource producers intensify efforts to improve separation efficiency, reduce operating costs, and meet tightening environmental requirements. Polyacrylamide (PAM) is a versatile, high-molecular-weight polymer widely used as a flocculant, coagulant aid, thickener, binder, and friction reducer. It is supplied in several forms—powder, emulsion, dispersion, and gel—and in different ionic types, including anionic, cationic, and nonionic grades. PAM plays a central role in solid–liquid separation across wastewater treatment, drinking water clarification, mining tailings management, pulp and paper processing, and industrial effluent treatment. It is also used in enhanced oil recovery, hydraulic fracturing, and certain agricultural and soil conditioning applications where water management and flow control matter. Between 2025 and 2034, the market outlook is expected to remain constructive, supported by expanding wastewater treatment capacity, stricter discharge norms, rising mining output and tailings volumes, and continued demand for performance chemicals that reduce energy and water use in processing operations. However, buyers are increasingly shifting from volume-driven procurement to performance-driven selection, emphasizing polymer efficiency, sludge dewatering outcomes, dosage optimization, and total cost of treatment rather than price per kilogram.

Market Overview

The Global Polyacrylamide Market was valued at $ 7.49 billion in 2025 and is projected to reach $ 16.03 billion by 2034, growing at a CAGR of 8.83%.

Industry Size and Market Structure

From a market structure perspective, the polyacrylamide market spans upstream monomer and feedstock supply, polymerization and formulation, distribution networks, and application services that support dosing, optimization, and compliance. Upstream value creation begins with acrylamide monomer availability and quality, alongside co-monomers and additives used to tailor molecular weight and charge density. Midstream, manufacturers produce PAM through controlled polymerization processes and then convert it into powders or emulsions depending on end-use requirements. Emulsion PAM is often favored where rapid dissolution and ease of handling are critical, while powder PAM can offer cost advantages and longer shelf stability in many industrial settings. Downstream, value increasingly shifts to technical service and application engineering because the effectiveness of PAM depends strongly on water chemistry, solids characteristics, shear conditions, and equipment configuration. Over the forecast period, value capture is expected to tilt toward suppliers that combine product portfolios with field support, digital dosing tools, and outcome-based optimization, particularly for municipal utilities and large mining and industrial accounts.

Key Growth Trends Shaping 2025–2034

A defining trend is the expansion and modernization of wastewater treatment infrastructure. Population growth, urbanization, industrialization, and tighter discharge regulations are driving higher demand for clarification, sludge thickening, and dewatering solutions. PAM remains a workhorse polymer for these processes, especially where operators need reliable performance across varying influent conditions. As many facilities upgrade from basic treatment toward advanced and tertiary processes, polymer consumption may rise due to higher solids capture targets and more stringent effluent quality requirements.

Second, mining and minerals processing is becoming an increasingly important demand center. Rising production of copper, iron ore, lithium, and other critical minerals increases tailings volumes and water recycling needs. PAM-based flocculants improve thickener performance, accelerate settling, and support water recovery in tailings management, enabling plants to recycle process water and reduce freshwater intake. Over time, the market is expected to see more specialized PAM formulations optimized for specific ore types, fine particle distributions, and high-salinity process waters.

Third, industrial water reuse and zero-liquid-discharge strategies are gaining momentum. Industries in chemicals, power generation, textiles, food processing, and refineries are adopting reuse systems to manage water scarcity and compliance risk. PAM supports pre-treatment and solids removal steps that protect membranes, reduce fouling, and improve overall system reliability. This trend is particularly strong in regions facing water stress, where reuse economics and regulatory pressure reinforce chemical demand.

Fourth, oil and gas applications continue to evolve. PAM and related polymers are used as friction reducers in hydraulic fracturing and in enhanced oil recovery where mobility control and improved sweep efficiency are targeted. While cyclic energy market dynamics create volatility, longer-term demand is supported by the need to optimize production efficiency and reduce water handling costs. Over the forecast period, suppliers that can provide stable performance in high-temperature, high-salinity, or challenging reservoir conditions may see premium opportunities, though environmental scrutiny remains a moderating factor.

Fifth, sustainability and regulatory focus is shaping product design and purchasing behavior. End users increasingly demand polymers that improve dewatered cake solids, reduce sludge volume, lower disposal costs, and minimize residual contaminants. In parallel, there is rising interest in improved handling safety, reduced dusting, and better dissolution characteristics that reduce operator exposure and operational downtime. As regulatory expectations rise, suppliers that can offer transparent product stewardship, robust quality consistency, and optimized dosing support are likely to benefit.

Finally, the market is seeing increased use of digital monitoring and process optimization. Utilities and industrial plants are deploying online turbidity, solids concentration, and flow measurement to adjust polymer dosing in real time. This helps reduce overuse, stabilize effluent quality, and lower overall chemical spend. PAM suppliers that integrate technical service with digital tools and performance-based contracts may gain a competitive advantage during 2025–2034.

Core Drivers of Demand

The strongest driver is the global need for effective water and wastewater treatment. PAM enables efficient solids removal and sludge dewatering, supporting compliance, reducing disposal volumes, and improving plant throughput.

A second driver is resource sector expansion and tailings management. Mining operations increasingly rely on PAM to improve thickening and water recovery, particularly where water scarcity and environmental oversight increase the value of efficient separation.

A third driver is water reuse and industrial efficiency. PAM supports process water recycling, reduces fouling risk in downstream filtration systems, and helps plants reduce freshwater dependency and operating costs.

Finally, tighter environmental regulations and sustainability commitments are pushing customers toward solutions that improve performance outcomes and reduce lifecycle costs, reinforcing demand for optimized PAM usage.

Browse more information:

Challenges and Constraints

Despite strong fundamentals, the market faces constraints. The first is feedstock and pricing volatility. Acrylamide monomer pricing and availability can influence polymer costs and contract structures, creating margin pressure for manufacturers and cost uncertainty for buyers.

Second, performance variability can be a challenge. PAM effectiveness depends on water chemistry, solids composition, pH, temperature, and shear conditions. Inadequate dosing systems, poor mixing, or changing influent characteristics can reduce performance, making technical support essential.

Third, handling and safety considerations remain important. Powder polymers require careful management to avoid dusting and ensure proper dissolution. Emulsions require appropriate storage and mixing, and plants must manage slip hazards and operational hygiene.

Fourth, environmental scrutiny and regulatory restrictions can affect certain applications, particularly in sensitive ecosystems and in oil and gas operations. Buyers may require stronger compliance documentation and careful selection to meet local regulations and discharge standards.

Segmentation Outlook

By ionic type, the market includes anionic PAM, cationic PAM, nonionic PAM, and amphoteric grades, selected based on solids characteristics and process requirements.

By physical form, PAM is supplied as powder/solid, emulsion, dispersion, and gel, with selection driven by handling preference, dissolution speed, and dosing infrastructure.

By application, key segments include municipal wastewater treatment, industrial effluent treatment, drinking water clarification (as a coagulant aid), mining and mineral processing, oil and gas (friction reduction and EOR), pulp and paper retention and drainage, and other niche uses such as soil conditioning and textiles.

By end user, the market spans municipal utilities, mining companies, industrial manufacturers, oil and gas operators, and specialized service providers.

Key Market Players

Ashland Inc., BASF SE, SNF Floerger Group, Kemira, Solvay, Petro China, Bluwat Chemicals, Black Rose Industries Ltd, Anhui Jucheng Fine Chemicals Co. Ltd, Xitao Polymer Co Ltd, Feymer, Ningxia Yongruida Carbon Co.Ltd, Merck, China National Petroleum Corporation, Beijing Hengju Oilfield Chemical Agent Co. Ltd., Anhui Tiarun Chemical, Daqing Petrochemical Company, Shandong Polymer Bio-chemicals Co. Ltd, Kasakrom, Cemotech, Chevron Philips, Eastman Chemical Company, Dupont, Exxon Mobil, Huntsman, INEOS Group, Lyondellbasell, Smolecule, Sigma Aldrich, Alfa Aesar, Otava Chemicals, Thermo Fisher Chemicals, MK Chemicals of Brazil Ltda, AXCHEM Brazil Chemical Industry, SNF Holding Company, Indo Jordan Chemicals Company, GAP Polymers, Ahlia chemicals company, Zamil Plastic Industries Ltd, Northern Vinyl Supplies, Lawsam Chemicals (U) Ltd, AECI Mining chemicals, Protea Chemicals

Regional Dynamics

North America remains a major market supported by established municipal treatment infrastructure, ongoing compliance upgrades, and strong mining and industrial demand, alongside steady oil and gas activity in certain basins. Europe sustains demand through strict discharge standards, advanced industrial wastewater treatment practices, and growing water reuse initiatives. Asia-Pacific is expected to be a key growth engine through 2034 due to rapid urbanization, industrial expansion, major mining activity in select countries, and increasing investment in wastewater treatment capacity. The Middle East and Africa present strong opportunities linked to industrial water reuse, desalination-related pre-treatment needs, and mining projects, while Latin America sees growth supported by mining expansion, municipal infrastructure upgrades, and industrial development.

Competitive Landscape and Forecast Perspective (2025–2034)

Competition spans large water treatment chemical companies, polymer specialists, regional formulators, and distributors that provide localized supply and service. Differentiation increasingly depends on product consistency, charge density and molecular weight control, performance in challenging waters, technical service capability, and dosing optimization support. Winning strategies through 2034 are expected to include: (1) expanding mining-tailored PAM portfolios for high solids and high-salinity conditions, (2) strengthening municipal sludge dewatering offerings with measurable cake solids improvements, (3) building integrated service models that include jar testing, onsite troubleshooting, and dosing system upgrades, (4) enabling digital dosing optimization to reduce overuse and stabilize compliance outcomes, and (5) improving supply chain resilience through diversified production and regional warehousing.

Looking ahead, the polyacrylamide market is positioned for steady expansion as separation efficiency and water management become more critical across municipalities and industry. The decade to 2034 will reward suppliers that move beyond commodity polymer supply and operate as performance partners—delivering consistent, application-specific PAM grades, supported by technical expertise and data-driven optimization that improves dewatering, lowers total treatment costs, and strengthens compliance in an increasingly resource- and regulation-constrained environment.

B

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0