Photomask Inspection Industry Outlook Covering Machine Learning Integration, Automation Tools, And Process Improvement Globally

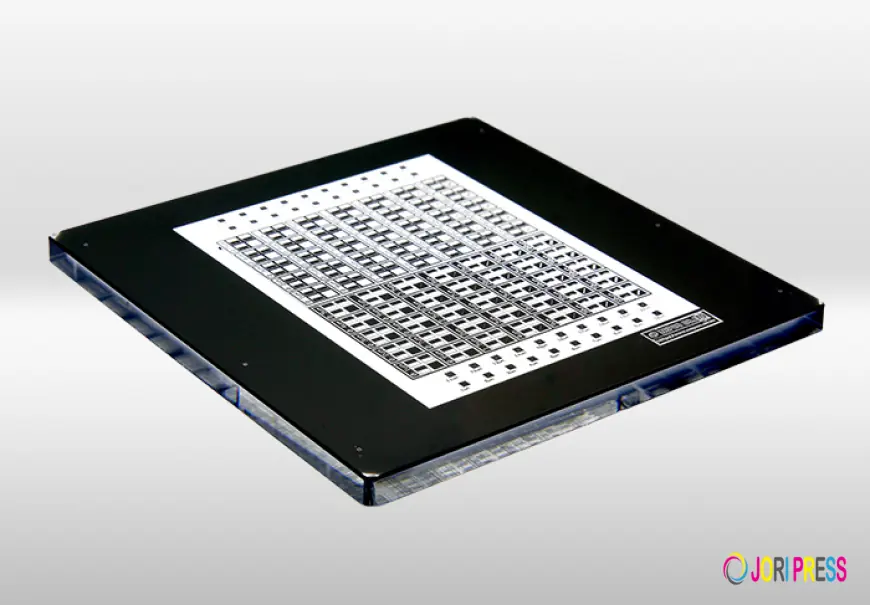

The photomask inspection market is increasingly adopting machine learning and automation tools to improve semiconductor fabrication processes. Photomasks are crucial in lithography, transferring precise circuit patterns onto silicon wafers. Even minor defects in masks can cause multiple faulty chips, reduced yield, and higher production costs. Machine learning integration allows inspection systems to automatically detect, classify, and predict defects with high accuracy. Automation tools enhance throughput, reduce human error, and maintain consistency in inspection. Process improvement strategies using analytics and real-time monitoring ensure that fabs can optimize production, reduce downtime, and achieve higher quality standards globally.

Role of Machine Learning in Inspection

Machine learning plays a transformative role in photomask inspection. By analyzing historical defect data, machine learning algorithms can classify defect types, predict recurring issues, and optimize inspection parameters. This predictive approach allows fabs to prevent yield loss before production issues occur. Integration with automated inspection systems enhances detection accuracy and reduces false positives. Over time, these systems learn from new defect patterns, continuously improving performance. Machine learning also enables real-time decision-making, providing actionable insights to fab engineers. This technology ensures higher production efficiency, reduced waste, and consistent product quality in increasingly complex semiconductor fabrication processes.

Automation Tools Enhancing Efficiency

Automation tools are essential for modern photomask inspection. Robotic handling ensures safe and consistent movement of photomasks, minimizing contamination and damage. Automated scanning systems combined with high-resolution imaging detect defects quickly across large mask areas. Software-driven automation allows dynamic adjustment of inspection parameters based on mask type and defect sensitivity. By reducing human intervention, automation ensures consistent results, faster throughput, and improved yield. Integration with fab operations allows inspection results to guide process adjustments in real-time, optimizing overall semiconductor manufacturing efficiency and reducing operational costs.

Process Improvement Strategies

Process improvement strategies are critical for maximizing yield and minimizing defects. Inspection data is analyzed to identify trends and root causes of recurring defects. Adjustments in lithography parameters, environmental controls, and mask handling procedures help prevent defects. Integration of automation and machine learning enables continuous monitoring and feedback, ensuring immediate corrective actions. Collaborative efforts between inspection systems and fab engineers allow fine-tuning of production processes for better efficiency. Streamlining workflows and implementing standardized procedures reduce variability, improve equipment utilization, and enhance overall product quality, supporting long-term growth and profitability in semiconductor manufacturing.

Types of Inspection Systems

Photomask inspection systems include optical, electron-beam, and hybrid solutions. Optical systems provide fast, large-area defect scanning, while electron-beam systems offer nanometer-level resolution for advanced semiconductor nodes. Hybrid systems combine both approaches, balancing speed and accuracy. Software integration, AI-assisted defect classification, and predictive analytics enhance system performance. Automated tools enable real-time feedback, adaptive scanning, and defect prioritization. Selection of the appropriate system depends on production volume, mask complexity, and required defect sensitivity. Continuous innovation in inspection technologies ensures fabs can meet the evolving demands of semiconductor fabrication globally.

Industry Adoption Trends

The adoption of machine learning and automation in photomask inspection is growing worldwide. Semiconductor manufacturers prioritize technologies that reduce defects, improve yield, and enhance process efficiency. Expansion of fabs in Asia-Pacific, North America, and Europe increases demand for advanced inspection solutions. Industry adoption trends indicate a shift towards integrated inspection systems combining high-resolution imaging, machine learning, and automation. Collaborative efforts with equipment vendors ensure optimal performance, seamless integration, and continuous process improvement. This adoption supports consistent production quality, faster time-to-market, and competitive advantage in a rapidly evolving semiconductor industry.

Applications Across Semiconductor Devices

Photomask inspection is essential for semiconductor chips, MEMS devices, and display panels. In semiconductor fabs, defect-free masks ensure reliable and high-performance devices. MEMS devices, including sensors and actuators, rely on precise masks for functional accuracy. Display panels such as LCD and OLED screens require masks with no defects to maintain uniform image quality. R&D centers use advanced inspection systems to validate new lithography techniques, materials, and mask designs. Increasing demand for smaller, faster, and more complex devices drives adoption of machine learning-based automated inspection systems, ensuring higher yields, optimized processes, and superior product quality globally.

Technological Advancements

Technological advancements in photomask inspection focus on AI, machine learning, automation, and high-resolution imaging. Real-time analytics, predictive maintenance, and adaptive scanning improve defect detection and classification. Automation minimizes human error and maintains consistency in inspection. Machine learning models continuously learn from new defect patterns, enhancing prediction and process optimization. Software tools provide detailed reports, trend analysis, and actionable insights for fabs. Robotics, automated handling, and integration with fab processes further enhance throughput, efficiency, and yield. These advancements collectively support reliable, scalable, and cost-effective semiconductor manufacturing to meet the growing demands of advanced electronic devices.

Market Drivers

Key drivers of the photomask inspection market include increasing demand for smaller semiconductor nodes, higher circuit complexity, and stricter quality standards in electronics manufacturing. Expansion of semiconductor fabs globally creates a growing need for automated, machine learning-based inspection tools. Integration of analytics, AI, and high-resolution imaging enhances defect detection, process optimization, and yield improvement. Manufacturers aim to reduce production costs, minimize waste, and maintain consistent output. The adoption of automated inspection and process improvement strategies positions fabs to meet global semiconductor demand efficiently, supporting innovation and competitiveness across consumer electronics, automotive, and industrial sectors.

Challenges

The photomask inspection market faces challenges despite its growth. Advanced inspection systems require significant investment, which may be prohibitive for smaller fabs. Increasing mask complexity demands continuous technology upgrades. Skilled personnel are required to operate automated systems and interpret analytics. Variability in detection accuracy among different tools can impact process consistency. To address these challenges, manufacturers adopt user-friendly automation, AI-assisted defect analysis, and training programs. Collaboration with equipment vendors ensures optimal performance and continuous process improvement, helping fabs overcome operational challenges while maintaining high-quality production standards.

Future Outlook

The future of photomask inspection is driven by machine learning integration, automation, and process improvement. Real-time monitoring, predictive analytics, and high-resolution imaging will define next-generation inspection systems. Expansion of fabs in key regions will increase global adoption. Continuous innovation in automated inspection tools will ensure defect-free masks, higher yield, and optimized semiconductor production. Companies investing in AI, analytics, and automation will lead the market, supporting efficient and reliable fabrication of increasingly complex electronic devices. Photomask inspection will remain a critical enabler for advanced semiconductor manufacturing, ensuring consistent quality and process efficiency worldwide.

Machine learning, automation, and process improvement strategies in photomask inspection ensure higher yield, defect-free production, and optimized semiconductor manufacturing processes globally. These technologies are essential for industry growth and competitiveness.

Learn More: pristinemarketinsights.com/photomask-inspection-market-report

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0