Nitto Seiko Automated Screwing Solutions: Revolutionizing Precision Assembly

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. Companies are constantly seeking ways to improve production speed while maintaining quality and consistency. Nitto Seiko, a leading innovator in the field of industrial automation, offers cutting-edge automated screwing solutions that help businesses achieve these goals. With decades of experience in fastener technology, Nitto Seiko's automated screwing systems are designed to increase productivity, ensure precision, and reduce the margin for human error. In this comprehensive guide, we will explore the key features, benefits, and applications of Nitto Seiko automated screwing solutions, and how they are transforming the manufacturing industry.

1. Overview of Nitto Seiko’s Automated Screwing Solutions

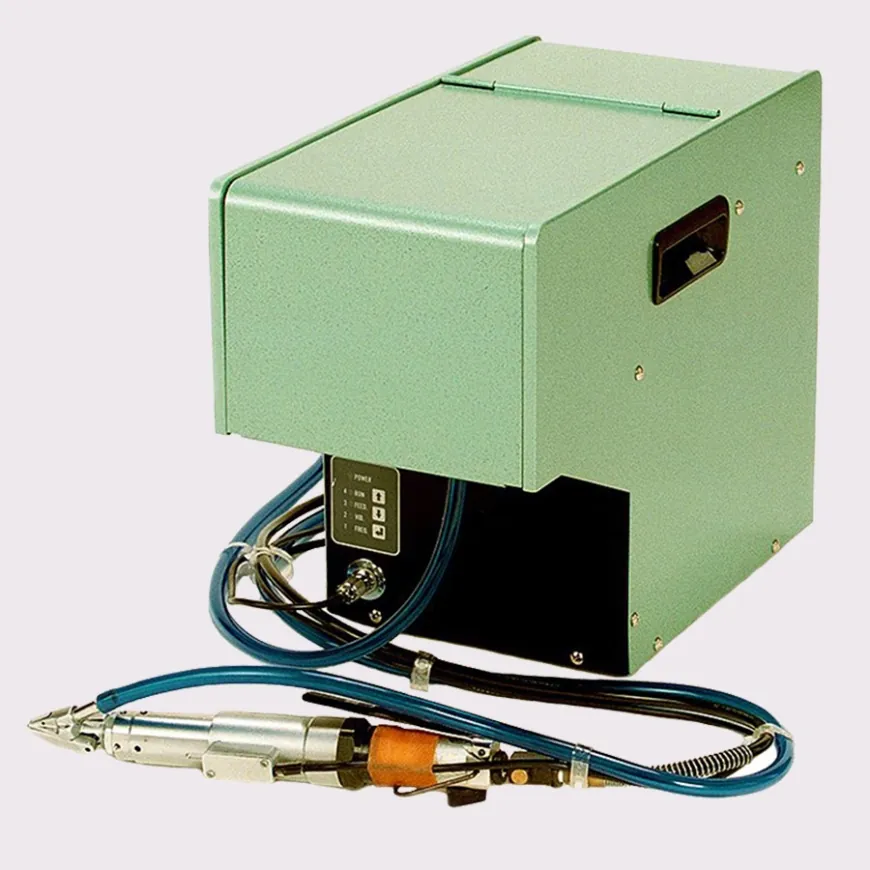

Nitto Seiko is a global leader in fastening technology and automation, known for its high-performance automated screw-driving machines and systems. These systems are engineered to handle the complexities of modern manufacturing processes, where speed, accuracy, and consistency are critical to success.

Automated screwing solutions from Nitto Seiko are used across a wide range of industries, including automotive, electronics, home appliances, and precision instruments. They offer a full spectrum of solutions, from fully automatic screw-driving robots to semi-automated systems, each designed to cater to specific production needs.

2. Key Features of Nitto Seiko Automated Screwing Solutions

a. Precision and Consistency

One of the most important advantages of Nitto Seiko automated screwing solutions is their ability to deliver unmatched precision and consistency. These systems are equipped with advanced torque control mechanisms that ensure every screw is fastened with the exact amount of torque required. This level of precision eliminates the risk of over-tightening or under-tightening screws, which can lead to defects or product failure.

The automated systems can also track and record data related to each screw tightening operation, providing full traceability for quality control purposes. This is particularly important in industries such as electronics or aerospace, where even a minor error in assembly can lead to costly recalls or safety hazards.

b. Speed and Efficiency

In high-volume production environments, speed is just as important as precision. Nitto Seiko's automated screwing solutions are designed to significantly reduce cycle times by automating the screw-driving process. These systems can fasten screws at a much faster rate than manual assembly, dramatically increasing throughput and reducing the time needed to complete each assembly.

Moreover, the automated systems can work continuously without fatigue, ensuring that production lines can operate at maximum capacity without downtime. This leads to improved productivity and allows manufacturers to meet tight deadlines without compromising on quality.

c. Versatility and Flexibility

Nitto Seiko offers a wide range of automated screwing solutions that can be customized to meet the specific needs of different industries. Their systems are capable of handling various types of screws, including small and delicate screws used in electronic devices, as well as larger, more robust fasteners used in automotive or construction applications.

These systems can be easily integrated into existing production lines and can accommodate changes in product design or assembly requirements. For example, manufacturers can switch between different screw sizes or patterns without significant reconfiguration, making Nitto Seiko’s solutions highly flexible for evolving production needs.

d. User-Friendly Interface

Despite the complexity of the technology, Nitto Seiko’s automated screwing solutions are designed with user-friendliness in mind. The machines come with intuitive interfaces that make it easy for operators to program, monitor, and adjust the system. This reduces the need for specialized training and allows operators to quickly get up to speed on how to use the equipment effectively.

Additionally, real-time monitoring features allow operators to detect and address issues immediately, minimizing downtime and ensuring that the production process remains as efficient as possible.

3. Benefits of Using Nitto Seiko Automated Screwing Solutions

a. Improved Product Quality

By automating the screwing process, manufacturers can achieve higher levels of accuracy and repeatability, leading to better overall product quality. Consistent torque control ensures that screws are fastened correctly every time, reducing the likelihood of assembly defects. This results in fewer product returns and a lower risk of failures in the field.

b. Cost Savings

Although the initial investment in automated screwing solutions may be significant, the long-term cost savings are substantial. Automation reduces the need for manual labor, minimizes errors, and improves overall efficiency, all of which contribute to lowering operational costs. Additionally, with fewer defective products and less rework required, manufacturers can save on materials and labor expenses.

c. Enhanced Safety

Manual screw driving, especially in high-volume production environments, can lead to repetitive strain injuries among workers. Nitto Seiko’s automated screwing systems reduce the need for manual intervention, thus creating a safer working environment. By automating repetitive tasks, companies can also mitigate the risk of human error, which can have significant safety and financial implications, especially in industries where precision is critical.

d. Scalability

Nitto Seiko’s automated screwing solutions are designed to grow with your business. Whether you’re a small manufacturer looking to automate part of your production line or a large enterprise seeking to overhaul your entire assembly process, Nitto Seiko offers scalable solutions that can be tailored to your specific requirements. As your production needs evolve, these systems can be adapted to handle increased workloads, new product designs, or different assembly techniques.

4. Applications of Nitto Seiko Automated Screwing Solutions

Nitto Seiko automated screwing solutions are used across a wide range of industries, each with its own unique set of challenges and requirements. Some common applications include:

a. Electronics Assembly

In the electronics industry, precision is critical. Small screws must be fastened with delicate care to avoid damaging sensitive components. Nitto Seiko’s systems are ideal for this industry, offering precise torque control and data tracking for quality assurance.

b. Automotive Industry

The automotive industry requires fasteners that can withstand high levels of stress and vibration. Nitto Seiko’s automated systems ensure that every screw is tightened to exact specifications, improving the reliability and safety of vehicles.

c. Medical Devices

Medical devices often have strict quality standards and require flawless assembly. Nitto Seiko’s automated screwing solutions provide the accuracy and consistency needed to meet these rigorous requirements, ensuring that every product is assembled to the highest standards.

d. Home Appliances

From refrigerators to washing machines, Nitto Seiko’s solutions are used to assemble home appliances quickly and efficiently. These systems ensure that each component is securely fastened, reducing the risk of product malfunctions.

Conclusion

Nitto Seiko automated screwing solutions are transforming the way manufacturers approach assembly tasks. By combining precision, speed, and versatility, these systems offer a comprehensive solution for businesses looking to improve product quality, enhance efficiency, and reduce costs. With applications spanning various industries, from electronics to automotive, Nitto Seiko’s technologies are paving the way for a new era of automated assembly. Investing in these advanced screwing systems is a strategic move for any manufacturer looking to stay competitive in today’s demanding market.