Navigating Challenges: Standardization in 3D Printing Materials"

3D Printing Materials Market By Type (Ceramics, Metals, and Plastics), By Form (Powder, Filament, Liquid), By Technology: (FDM, SLS, SLA, DMLS, Others), By Application:(Prototyping, Manufacturing, Others), By End-Use (Aerospace & Defense, Automotive, Medical, and Consumer Products & Industrial), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2023-2033

Overview

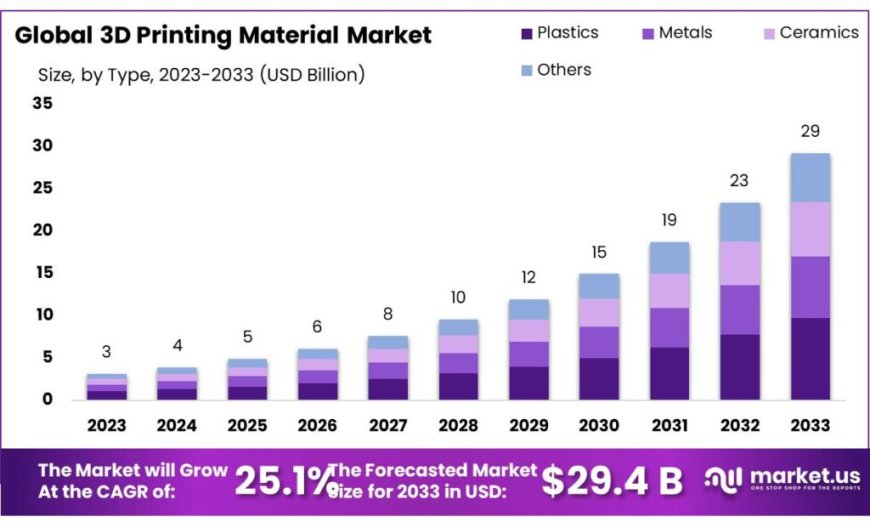

3D Printing Materials Market size is projected to reach USD 29.4 billion by 2033 from USD 3.12 billion in 2023 – at a compound annual compound growth rate of 25.1% over its predicted lifespan between 2023-2033.

The 3D printing materials market refers to the industry focused on producing and supplying the diverse materials used in 3D printing technologies. This market encompasses a wide range of materials, including plastics, metals, ceramics, and composites, which are essential for creating 3D-printed objects.

As more industries such as aerospace, defense, automotive, healthcare, and consumer goods adopt 3D printing for production, the demand for high-performance materials is skyrocketing. This growth is driven by the need for materials that can meet specific performance criteria, such as strength, flexibility, and heat resistance, which are critical for the intricate and demanding applications in these sectors.

Download a sample report in MINUTES@ https://market.us/report/3d-printing-materials-market/request-sample/

Technological innovations are at the heart of the 3D printing materials market's expansion. Advances in material science and 3D printing technologies have made it possible to create more complex and durable components, thus revolutionizing traditional manufacturing processes. The ability to produce custom and intricate designs with high precision and reduced waste is particularly appealing to industries seeking efficiency and cost-effectiveness.

As a result, the market is experiencing exponential growth, with increasing investments in research and development, leading to the continuous introduction of new materials and enhanced capabilities.

Кеу Маrkеt Ѕеgmеntѕ

By Type

-

Photopolymers

-

Metals

-

Other Materials

By Form

-

Powder

-

Filament

-

Liquid

By Technology

-

FDM

-

SLS

-

SLA

-

DMLS

-

Others

By Application

-

Prototyping

-

Manufacturing

-

Others

End-Use

-

Aerospace & Defense Industry

-

Automotive Sector

-

Medical

-

Consumer Products & Industrial Sectors

-

Other Applications

The 3D printing materials market is witnessing remarkable growth, driven by the increasing adoption across diverse industries such as aerospace, defense, automotive, and healthcare.. Technological advancements and the need for high-performance materials have fueled demand for photopolymers, thermoplastics, and metal alloys. Powder-based and filament forms dominate, with applications in sectors like prototyping, manufacturing, and end-use parts production. The market's expansion is further bolstered by the rising use of 3D printing in medical applications, consumer products, and industrial manufacturing, highlighting its transformative impact on traditional processes.

Кеу Market Рlауеrѕ

-

Höganäs AB

-

3D Systems Corporation

-

General Electric

-

Arkema S.A.

-

Royal DSM N.V.

-

Stratasys Ltd.

-

Evonik Industries AG.

-

EOS GmbH

-

Sandvik AB

-

Other Key Major players

Driver:

The development of new industrial-grade 3D printing materials is driving innovation across industries. Beyond traditional plastics, advancements now enable the use of ceramics, metals, and biocompatible materials, expanding 3D printing capabilities in electronics and healthcare. Innovations like metal-infused filaments allow standard FDM printers to create objects in materials like bronze and copper, while composites gain traction, especially in aerospace applications.

Restraint:

A significant challenge in the 3D printing industry is the lack of standardized process control. Variability in process variables and material characteristics across different machines and manufacturers leads to inconsistent outcomes. Limited monitoring techniques hinder the ability to achieve consistent quality.

Opportunity:

The adoption of 3D printing technology in home printing represents a promising opportunity for market growth. The availability of affordable home 3D printers has democratized manufacturing capabilities, driving increased demand for 3D printing materials. These printers are now accessible in homes, offices, and retail settings, offering cost-effective and rapid production of customized goods.

Challenge:

A key challenge facing the 3D printing materials market is the production of low-cost materials. High material costs have limited the widespread adoption of 3D printing in various sectors, particularly in economically sensitive industries like automotive. While luxury and high-end sectors utilize these materials, achieving cost-effective production methods remains a barrier.

Overview

3D Printing Materials Market size is projected to reach USD 29.4 billion by 2033 from USD 3.12 billion in 2023 – at a compound annual compound growth rate of 25.1% over its predicted lifespan between 2023-2033.

The 3D printing materials market refers to the industry focused on producing and supplying the diverse materials used in 3D printing technologies. This market encompasses a wide range of materials, including plastics, metals, ceramics, and composites, which are essential for creating 3D-printed objects.

As more industries such as aerospace, defense, automotive, healthcare, and consumer goods adopt 3D printing for production, the demand for high-performance materials is skyrocketing. This growth is driven by the need for materials that can meet specific performance criteria, such as strength, flexibility, and heat resistance, which are critical for the intricate and demanding applications in these sectors.

Download a sample report in MINUTES@ https://market.us/report/3d-printing-materials-market/request-sample/

Technological innovations are at the heart of the 3D printing materials market's expansion. Advances in material science and 3D printing technologies have made it possible to create more complex and durable components, thus revolutionizing traditional manufacturing processes. The ability to produce custom and intricate designs with high precision and reduced waste is particularly appealing to industries seeking efficiency and cost-effectiveness.

As a result, the market is experiencing exponential growth, with increasing investments in research and development, leading to the continuous introduction of new materials and enhanced capabilities.

Кеу Маrkеt Ѕеgmеntѕ

By Type

-

Photopolymers

-

Metals

-

Other Materials

By Form

-

Powder

-

Filament

-

Liquid

By Technology

-

FDM

-

SLS

-

SLA

-

DMLS

-

Others

By Application

-

Prototyping

-

Manufacturing

-

Others

End-Use

-

Aerospace & Defense Industry

-

Automotive Sector

-

Medical

-

Consumer Products & Industrial Sectors

-

Other Applications

The 3D printing materials market is witnessing remarkable growth, driven by the increasing adoption across diverse industries such as aerospace, defense, automotive, and healthcare.. Technological advancements and the need for high-performance materials have fueled demand for photopolymers, thermoplastics, and metal alloys. Powder-based and filament forms dominate, with applications in sectors like prototyping, manufacturing, and end-use parts production. The market's expansion is further bolstered by the rising use of 3D printing in medical applications, consumer products, and industrial manufacturing, highlighting its transformative impact on traditional processes.

Кеу Market Рlауеrѕ

-

Höganäs AB

-

3D Systems Corporation

-

General Electric

-

Arkema S.A.

-

Royal DSM N.V.

-

Stratasys Ltd.

-

Evonik Industries AG.

-

EOS GmbH

-

Sandvik AB

-

Other Key Major players

Driver:

The development of new industrial-grade 3D printing materials is driving innovation across industries. Beyond traditional plastics, advancements now enable the use of ceramics, metals, and biocompatible materials, expanding 3D printing capabilities in electronics and healthcare. Innovations like metal-infused filaments allow standard FDM printers to create objects in materials like bronze and copper, while composites gain traction, especially in aerospace applications.

Restraint:

A significant challenge in the 3D printing industry is the lack of standardized process control. Variability in process variables and material characteristics across different machines and manufacturers leads to inconsistent outcomes. Limited monitoring techniques hinder the ability to achieve consistent quality.

Opportunity:

The adoption of 3D printing technology in home printing represents a promising opportunity for market growth. The availability of affordable home 3D printers has democratized manufacturing capabilities, driving increased demand for 3D printing materials. These printers are now accessible in homes, offices, and retail settings, offering cost-effective and rapid production of customized goods.

Challenge:

A key challenge facing the 3D printing materials market is the production of low-cost materials. High material costs have limited the widespread adoption of 3D printing in various sectors, particularly in economically sensitive industries like automotive. While luxury and high-end sectors utilize these materials, achieving cost-effective production methods remains a barrier.