Metal Matrix Composites Market Trends: Lightweighting, Wear Resistance, and High-Temperature Performance (2025–2034)

The metal matrix composites (MMC) market is moving into a decisive adoption phase as aerospace, defense, automotive, electronics, and industrial manufacturers seek materials that outperform conventional alloys in strength-to-weight ratio, stiffness, wear resistance, thermal stability, and heat dissipation. Metal matrix composites are engineered materials in which a metal—commonly aluminum, magnesium, titanium, copper, or nickel—acts as the matrix, reinforced with ceramic particles, whiskers, fibers, or continuous reinforcements such as silicon carbide, alumina, boron carbide, carbon-based reinforcements, and other advanced ceramics. By combining the ductility and toughness of metals with the hardness and high-temperature performance of ceramics, MMCs offer a unique performance envelope that is increasingly relevant in a decade defined by electrification, lightweighting, higher operating temperatures, and efficiency-driven design. Between 2025 and 2034, the market outlook is expected to remain constructive, supported by the scaling of electric mobility, growing aircraft production and next-generation engine programs, demand for high-reliability electronics packaging, and industrial modernization that prioritizes longer component life and reduced maintenance.

Market Overview

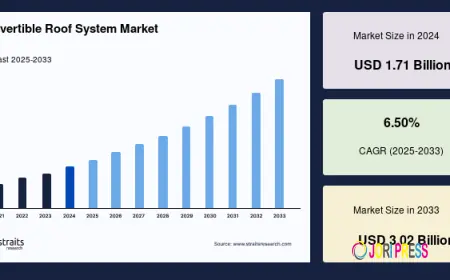

The Global Metal Matrix Composites Market was valued at $ 744.53 million in 2025 and is projected to reach $ 1244 million by 2034, growing at a CAGR of 5.87%.

Industry Size and Market Structure

From a market structure perspective, the MMC market spans upstream reinforcement material suppliers, matrix metal producers, composite fabricators, component manufacturers, and downstream OEMs integrating MMC parts into critical systems. Upstream value creation begins with high-quality ceramic reinforcements—particles, short fibers, continuous fibers—and the specialized surface treatments required to ensure wetting, bonding, and stable interfaces with the metal matrix. Matrix selection and alloy chemistry are equally important, as they determine processability, corrosion behavior, thermal conductivity, and mechanical properties. Midstream, MMC production is driven by processing routes such as powder metallurgy, stir casting, squeeze casting, infiltration, spray deposition, additive manufacturing variants, and diffusion bonding methods. Each route carries distinct trade-offs in cost, volume scalability, defect control, and property consistency. Downstream, value increasingly shifts to precision machining, near-net shaping, joining solutions, coatings, and qualification services, because many MMC parts operate in demanding environments where performance guarantees and tight tolerances matter as much as the material itself. Over the forecast period, value capture is expected to tilt toward suppliers that can deliver repeatable, certified MMC components at scale, supported by robust quality systems, traceability, and long-term supply reliability.

Key Growth Trends Shaping 2025–2034

A defining trend is the acceleration of lightweighting and performance-driven substitution in transportation. In aerospace and defense, MMCs are relevant for structural components, rotorcraft parts, satellite structures, missile systems, and engine-related hardware where stiffness, fatigue performance, and thermal stability are required. While carbon fiber composites dominate many airframe structures, MMCs occupy a complementary niche where metals are preferred for conductivity, high-temperature capability, or impact tolerance but need reinforcement to push performance beyond traditional alloys. In automotive and motorsports, MMCs are increasingly evaluated for brake rotors, pistons, cylinder liners, suspension components, and drivetrain elements that benefit from wear resistance and reduced mass. As electric vehicles grow, lightweighting remains strategic, but MMC adoption will depend heavily on cost engineering and scalable manufacturing routes.

Second, electrification and power electronics are strengthening demand for thermally conductive, dimensionally stable materials. MMCs—particularly aluminum- or copper-based composites—are used in heat sinks, baseplates, and electronic packaging where high thermal conductivity, low coefficient of thermal expansion mismatch, and reliability under thermal cycling are critical. As power densities rise in inverters, chargers, data centers, renewable energy converters, and industrial drives, thermal management becomes a differentiating factor, expanding the addressable market for MMC solutions that can handle heat and vibration while maintaining dimensional stability.

Third, industrial and energy-sector adoption is growing for wear-intensive and high-load components. Pumps, compressors, tooling systems, bearings, and downhole or abrasive-handling applications can benefit from MMCs due to improved wear resistance and longer service life. This trend is reinforced by maintenance cost pressures and the growing preference for components that reduce downtime, extend replacement intervals, and perform consistently under harsh conditions.

Fourth, the market is seeing increased activity in process innovation and near-net-shape manufacturing. Traditional MMC production has been constrained by cost, variability, and machinability challenges. Manufacturers are investing in better dispersion control, improved interfacial bonding, reduced porosity, and optimized reinforcement architectures. Near-net-shape approaches, advanced casting techniques, and selective reinforcement placement are emerging to reduce scrap and machining time, making MMC parts more economically viable.

Fifth, qualification and standardization efforts are becoming more important. MMCs are often used in safety-critical systems where certification, repeatability, and long validation cycles are mandatory. Suppliers that invest in data packages, standardized test methods, statistical process control, and long-term performance records are better positioned to secure aerospace and defense programs, as well as high-reliability industrial applications.

Core Drivers of Demand

The strongest driver is performance requirements that exceed the limits of monolithic metals. MMCs provide high stiffness, superior wear resistance, better thermal stability, and improved fatigue performance compared to conventional alloys, enabling lighter designs, longer life, and improved system efficiency.

A second driver is thermal management and reliability in electronics and electrified systems. As devices become smaller and more powerful, effective heat dissipation and dimensional stability are essential. MMCs address these needs in ways that conventional metals may not, particularly under thermal cycling and vibration.

A third driver is lifecycle cost reduction in industrial environments. Although MMCs can be more expensive upfront, they often reduce total cost of ownership through longer component life, fewer replacements, and less downtime, making them attractive in high-wear and high-load conditions.

Finally, defense modernization and space-sector growth support demand for materials that perform under extreme mechanical and thermal conditions, where reliability and weight efficiency have high strategic value.

Challenges and Constraints

Despite strong drivers, MMC adoption faces meaningful constraints. The first is cost and scalability. Many MMC processes require specialized equipment, controlled environments, and expensive reinforcements. Achieving high-volume manufacturing with consistent properties remains challenging, especially for cost-sensitive automotive applications.

Second, machinability and joining complexity can limit broader adoption. Reinforcements increase tool wear and complicate machining, and joining MMCs to conventional metals requires careful control to prevent defects, galvanic corrosion, or weak interfaces. These factors can increase production time and cost unless addressed through optimized tooling, coatings, and design-for-manufacture practices.

Third, property consistency and defect control remain critical hurdles. Porosity, reinforcement clustering, and interfacial reactions can compromise performance, requiring advanced process control and inspection. OEMs demand reliable statistical consistency, especially in aerospace and high-reliability electronics.

Fourth, supply chain maturity varies by region and reinforcement type. Secure sourcing of high-quality reinforcements and stable production capacity can be limiting factors, particularly for specialized fiber-based MMCs.

Segmentation Outlook

By matrix material, the market includes aluminum MMCs, magnesium MMCs, titanium MMCs, copper MMCs, and nickel-based MMCs, each chosen for a distinct balance of strength, thermal performance, corrosion resistance, and cost.

By reinforcement type, MMCs include particle-reinforced composites, short fiber/whisker reinforced composites, and continuous fiber reinforced composites, with performance and cost rising with reinforcement sophistication.

By manufacturing route, key segments include powder metallurgy, stir casting, squeeze casting, infiltration processes, spray deposition, and emerging additive-enabled approaches.

By end user, the market spans aerospace and defense, automotive and motorsports, electronics and semiconductors, industrial machinery, energy systems, and specialized medical or sporting applications.

Key Market Players

3M, GKN Aerospace, Materion Corporation, CPS Technologies, DWA Aluminum Composites, Sandvik AB, Sumitomo Electric, SGL Carbon, Plansee Group, Deutsche Edelstahlwerke, Metal Matrix Cast Composites, Aluminum Matrix Composites Ltd., RSP Technology, Hitachi Metals, COMTEC

Regional Dynamics

North America remains a major market due to its strong aerospace and defense base, advanced materials ecosystem, and demand for high-performance industrial components. Europe sustains growth through aerospace manufacturing, automotive engineering capabilities, and increasing emphasis on efficiency and advanced thermal management solutions. Asia-Pacific is expected to be a key growth engine through 2034, supported by large-scale electronics manufacturing, industrial expansion, and increasing investment in aerospace and electric mobility supply chains. The Middle East and Africa show selective opportunities in defense, energy, and high-wear industrial applications, while Latin America’s growth is expected to be more project-driven, linked to industrial modernization and localized aerospace or mining-related demand.

Competitive Landscape and Forecast Perspective (2025–2034)

Competition spans advanced materials companies, specialized MMC fabricators, casting and powder metallurgy firms, and component manufacturers that integrate MMCs into finished systems. Differentiation increasingly depends on process control, repeatability, cost engineering, machining solutions, and qualification capability. Winning strategies through 2034 are expected to include: (1) scaling electronics thermal management offerings with consistent performance and strong reliability data, (2) expanding aerospace and defense-qualified MMC portfolios backed by certification-ready documentation, (3) developing hybrid designs that use MMCs only where needed to optimize cost, (4) improving manufacturability through near-net-shape production and better machinability solutions, and (5) strengthening supply chains for reinforcements and matrix materials while improving traceability and quality assurance.

Looking ahead, the metal matrix composites market is positioned for steady expansion as industries demand materials that bridge the gap between metals and ceramics—delivering lightweight strength, wear resistance, and thermal performance in a manufacturable form. The decade to 2034 will reward suppliers that combine materials science with scalable production, qualification discipline, and application engineering—helping OEMs move from niche MMC deployments to broader platform integration in electrified systems, aerospace components, high-reliability electronics, and wear-critical industrial machinery.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0