Magnesia Ceramic Foam Filter Market Trends: High-Temperature Filtration, Pore Control, and Yield Improvement (2025–2034)

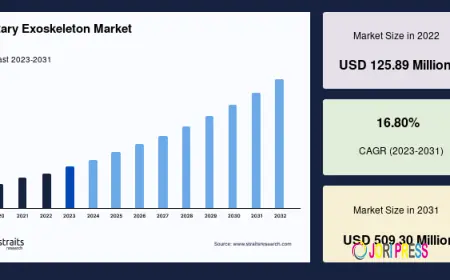

The Global Magnesia Ceramic Foam Filter Market Size is valued at $ 240.6 Million in 2025. Worldwide sales of Magnesia Ceramic Foam Filter Market are expected to grow at a significant CAGR of 5.3%, reaching $ 345 Million by the end of the forecast period in 2032.

The magnesia ceramic foam filter market is entering a quality-critical decade as metal producers and foundries intensify efforts to improve melt cleanliness, reduce casting defects, and increase yield in high-value metallurgical applications. Magnesia ceramic foam filters are porous, three-dimensional ceramic structures made primarily from magnesium oxide (MgO), designed to remove inclusions, non-metallic particles, slag residues, and dross from molten metals. Their open-cell foam architecture provides a high surface area and tortuous flow path, enabling effective filtration while maintaining acceptable flow rates. These filters are primarily used in demanding casting environments where high temperature stability, chemical compatibility, and thermal shock resistance are essential. Between 2025 and 2034, the market outlook is expected to remain constructive, supported by continued production of steel, iron, and non-ferrous metals, rising adoption of quality-focused casting practices, growing requirements for cleaner metals in automotive and industrial components, and the expansion of precision casting and continuous casting operations. However, the value equation is shifting from “basic filtration consumables” toward performance-assured filtration systems, where consistent pore structure, thermal stability, filtration efficiency, and predictable service life directly translate into lower scrap rates and improved downstream machining and finishing economics.

Market Overview

The Global Magnesia Ceramic Foam Filter Market Size is valued at $ 240.6 Million in 2025. Worldwide sales of Magnesia Ceramic Foam Filter Market are expected to grow at a significant CAGR of 5.3%, reaching $ 345 Million by the end of the forecast period in 2032.

Industry Size and Market Structure

From a market structure perspective, the magnesia ceramic foam filter market spans upstream raw material supply, midstream filter manufacturing and quality assurance, and downstream distribution into foundries, steel plants, and casting operations. Upstream value creation begins with high-purity magnesia and complementary ceramic constituents, binders, foaming agents, and coating materials that determine porosity, strength, and chemical resistance. Midstream, manufacturers produce filters through replication processes that create a foam-like ceramic network, followed by firing and finishing to achieve the required pore-per-inch (PPI) rating, thickness, and mechanical integrity. Product performance depends heavily on process control: uniform porosity, consistent strut thickness, and minimal defects reduce the risk of breakage or bypass during filtration. Downstream, filters are supplied through direct agreements with large metal producers, through refractory and foundry consumables distributors, or as part of integrated molten metal treatment systems. Over the forecast period, value capture is expected to tilt toward suppliers that offer application engineering support, customized filter geometries, and robust quality systems, because end users increasingly judge suppliers on casting yield improvement, defect reduction, and process stability rather than unit price alone.

Key Growth Trends Shaping 2025–2034

A defining trend is the increased emphasis on melt cleanliness and defect reduction in both ferrous and non-ferrous casting. Inclusions, oxide films, and slag particles can lead to porosity, cracks, poor surface finish, and downstream machining issues. As OEMs tighten quality standards—particularly in automotive, industrial machinery, and energy components—foundries are investing in filtration to improve consistency and reduce rejection rates. Magnesia-based filters are particularly relevant in high-temperature and chemically aggressive conditions where other ceramic compositions may be less stable.

Second, modernization of foundry operations and the expansion of precision casting are supporting filtration adoption. Investment in automated molding lines, improved melt handling, and tighter process control increases the value of stable filtration performance. In high-value castings, even a small reduction in scrap can justify premium filtration solutions. Over time, filtration is expected to move from a “problem-solving add-on” to a standard step in quality-focused casting lines.

Third, growth in steel and iron processing quality requirements is influencing the broader ceramic filter ecosystem. While magnesia ceramic foam filters are used in select molten metal streams and specialized applications, the broader trend of cleaner metal production and improved downstream product quality supports increased adoption of filtration consumables. In addition, the push toward thinner-gauge steel products, improved surface quality, and high-strength alloys increases sensitivity to inclusion-related defects, indirectly supporting filtration demand.

Fourth, product engineering trends are focusing on optimized porosity and flow behavior. End users want filters that remove inclusions without causing excessive pressure drop, flow turbulence, or premature clogging. This is driving demand for well-controlled PPI ratings, multi-layer or gradient porosity designs, and improved coatings that enhance wetting and capture efficiency. Suppliers that can tailor filtration to specific melt chemistry, temperature profiles, and casting rates will gain competitive advantage.

Fifth, sustainability and yield improvement are becoming stronger procurement drivers. Filtration that reduces scrap, re-melting, and rework directly reduces energy consumption and emissions per ton of finished metal. As metal producers adopt sustainability KPIs and carbon reporting, consumables that improve yield and reduce waste gain strategic importance, even if they carry a higher upfront cost.

Finally, the market is being shaped by supply chain reliability and quality consistency. Filters are consumables, and interruptions in supply can halt production or compromise quality. Large foundries increasingly favor suppliers that can provide stable delivery, consistent product performance, and technical service support, including troubleshooting and process optimization.

Core Drivers of Demand

The strongest driver is the need to reduce casting defects and improve yield. Filtration removes inclusions and slag particles that cause quality failures, enabling higher acceptance rates and lower scrap.

A second driver is rising quality expectations from end-user industries. Automotive, industrial machinery, and energy sectors increasingly demand consistent mechanical properties and surface quality, pushing foundries toward better melt treatment practices.

A third driver is the economics of metal processing. Scrap reduction, fewer downtime events, and improved machining behavior translate into tangible cost savings that often justify filtration investments.

Finally, sustainability and energy efficiency are reinforcing adoption. Yield improvement reduces re-melt requirements and energy use, aligning filtration with decarbonization objectives in metal production.

Challenges and Constraints

Despite supportive drivers, the market faces constraints. The first is the risk of filter breakage or thermal shock in poorly controlled processes. Filters must withstand rapid temperature changes and mechanical stresses; improper preheating, mishandling, or mismatched filter selection can lead to failures.

Second, cost sensitivity remains, especially in commodity casting operations where margins are thin. Some producers may resist higher-cost filtration solutions unless benefits are clearly quantified through defect reduction and yield improvement.

Third, performance can be application-specific. Melt chemistry, temperature, turbulence, and casting design strongly influence filtration outcomes. This creates a need for technical support and may slow adoption where foundries lack expertise in filter selection and process integration.

Fourth, competition from alternative ceramic compositions and filtration methods can limit growth. Alumina, zirconia, silicon carbide, and other ceramics are used depending on metal type and process conditions, and in some cases, electromagnetic or other melt treatment methods may complement or substitute filtration.

Segmentation Outlook

By pore structure, the market includes filters of different PPI ratings tailored to capture different inclusion sizes and manage flow behavior.

By application, key segments include ferrous foundries, non-ferrous foundries, steel and iron processing streams, and specialty alloy casting where temperature and chemistry demand robust filtration.

By end use industry, demand is linked to automotive castings, industrial machinery components, energy and power equipment, construction and infrastructure metal products, and high-performance engineering applications.

By distribution channel, filters are sold through direct supply agreements, refractory and foundry consumable distributors, and integrated molten metal treatment providers.

Key Market Players

- SELEE Corporation

- Induceramic

- Saint-Gobain Performance Ceramics & Refractories

- ASK Chemicals

- JINTAI Ceramic Materials Co., Ltd.

- Drache GmbH

- Vesuvius plc

- Foseco Foundry Division

- Pingxiang Sanhe Ceramics Co., Ltd.

- Pingxiang Chemshun Ceramics Co., Ltd.

- Jiangxi Jintai Special Material LLC

- Tech Ceramic Co., Ltd.

- STI Group

- Protech Industries

- Jiangsu Province Yixing Nonmetallic Chemical Machinery Factory Co., Ltd.

Regional Dynamics

North America remains a significant market due to established foundry operations, demand for high-quality castings, and continued investment in industrial and automotive manufacturing. Europe sustains growth through strong quality standards, advanced casting practices, and pressure to reduce scrap and emissions. Asia-Pacific is expected to be the key growth engine through 2034 due to large-scale metal production, expanding foundry capacity, and rising adoption of quality-focused melt treatment in automotive and industrial sectors. The Middle East and Africa present opportunities linked to metal industry expansion and infrastructure development, while Latin America sees growth through localized foundry modernization and increasing demand for higher-quality cast components.

Competitive Landscape and Forecast Perspective (2025–2034)

Competition spans ceramic filter manufacturers, refractory suppliers with filtration portfolios, and specialized foundry consumable companies. Differentiation increasingly depends on thermal shock resistance, consistent pore structure, filtration efficiency, product reliability, and technical service. Winning strategies through 2034 are expected to include: (1) developing application-optimized filter grades for different metal streams and temperatures, (2) improving manufacturing consistency and quality assurance to reduce failure risk, (3) offering technical support for filter selection, gating design integration, and preheating practices, (4) expanding regional production and distribution to improve supply reliability, and (5) positioning filtration as a yield- and sustainability-enhancing solution that reduces scrap and energy consumption.

Looking ahead, the magnesia ceramic foam filter market is positioned for steady growth as foundries and metal producers intensify focus on melt cleanliness, defect reduction, and productivity. The decade to 2034 will reward suppliers that combine robust materials engineering with process expertise—delivering reliable filtration consumables that help customers improve casting quality, reduce waste, and meet rising performance and sustainability requirements across global metal value chains.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0