Hydraulic Seals Guide: Types, Functions, and Maintenance Tips

Hydraulic seals guide explaining types, functions, materials, and maintenance tips. Learn how hydraulic seals prevent leakage and improve system performance.

Hydraulic seals are critical components in hydraulic systems, playing a key role in preventing fluid leakage, maintaining pressure, and ensuring smooth system operation. Used across industries such as manufacturing, construction, agriculture, automotive, and aerospace, hydraulic seals directly impact system efficiency, safety, and equipment lifespan. This guide explains the types of hydraulic seals, their functions, and essential maintenance tips to help you get the best performance from your hydraulic systems.

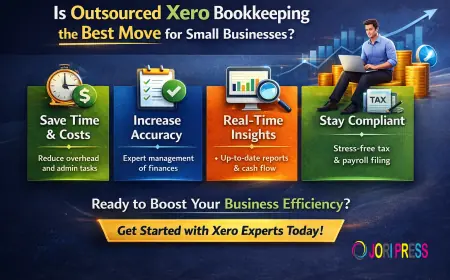

What Are Hydraulic Seals?

Hydraulic seals are designed to block fluid flow between different pressure zones in a hydraulic system. They contain hydraulic oil, prevent contamination from entering the system, and allow components such as pistons and rods to move smoothly under high pressure. Without proper sealing, hydraulic systems can suffer from leaks, pressure loss, overheating, and premature component failure.

Types of Hydraulic Seals

There are several types of hydraulic seals, each designed for specific applications and operating conditions:

1. Piston Seals

Piston seals are used in hydraulic cylinders to seal the piston head, preventing fluid from passing between the piston and cylinder bore. They are commonly used in double-acting cylinders and are designed to handle high pressure and dynamic movement.

2. Rod Seals

Rod seals prevent hydraulic fluid from leaking out of the cylinder where the piston rod extends. They also help maintain system pressure and protect external components from oil leakage.

3. Wiper Seals (Scraper Seals)

Wiper seals remove dirt, dust, moisture, and debris from the piston rod as it retracts into the cylinder. This prevents contaminants from entering the hydraulic system and damaging internal components.

4. O-Rings

O-rings are one of the most widely used sealing solutions in hydraulic systems. They are simple, cost-effective, and suitable for both static and dynamic applications when properly installed.

5. Backup Rings

Backup rings are used alongside O-rings to prevent extrusion under high pressure. They improve seal durability and performance in demanding applications.

6. Wear Rings (Guide Rings)

Wear rings do not seal fluid but guide moving components, reducing metal-to-metal contact and ensuring proper alignment within hydraulic cylinders.

Functions of Hydraulic Seals

Hydraulic seals perform several essential functions, including:

-

Preventing fluid leakage under high pressure

-

Maintaining system pressure and efficiency

-

Protecting internal components from contamination

-

Reducing friction and wear between moving parts

-

Ensuring smooth and controlled movement of hydraulic components

By performing these functions effectively, hydraulic seals help reduce downtime and extend equipment life.

Common Materials Used in Hydraulic Seals

Hydraulic seals are manufactured from different materials depending on temperature, pressure, and fluid compatibility. Common materials include nitrile rubber (NBR), polyurethane (PU), fluorocarbon (FKM), and PTFE. Choosing the right material is essential for durability and performance.

Hydraulic Seal Maintenance Tips

Proper maintenance of hydraulic seals helps prevent system failures and costly repairs. Follow these tips for optimal performance:

-

Inspect seals regularly for wear, cracks, or deformation

-

Replace seals at recommended intervals or during routine maintenance

-

Keep hydraulic fluid clean to reduce contamination-related damage

-

Avoid improper installation, which can cause seal failure

-

Monitor operating temperature and pressure to stay within seal limits

Conclusion

Hydraulic seals are small components with a major impact on hydraulic system performance. Understanding the different types of hydraulic seals, their functions, and proper maintenance practices helps ensure efficient operation, reduced leakage, and longer equipment life. Investing in the right seals and maintaining them correctly is essential for reliable and cost-effective hydraulic system performance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0