How to Identify Faulty Signal Control Cable Before They Fail

Signal control cables play a vital role in keeping machines and communication systems running smoothly. Faults such as visible damage, loose connectors, interference, overheating, or stiffness can signal early cable failure. Regular inspections, electrical testing, and preventive maintenance help detect issues before they cause costly downtime or safety risks. Training staff and planning timely replacements ensure reliable performance and uninterrupted operations.

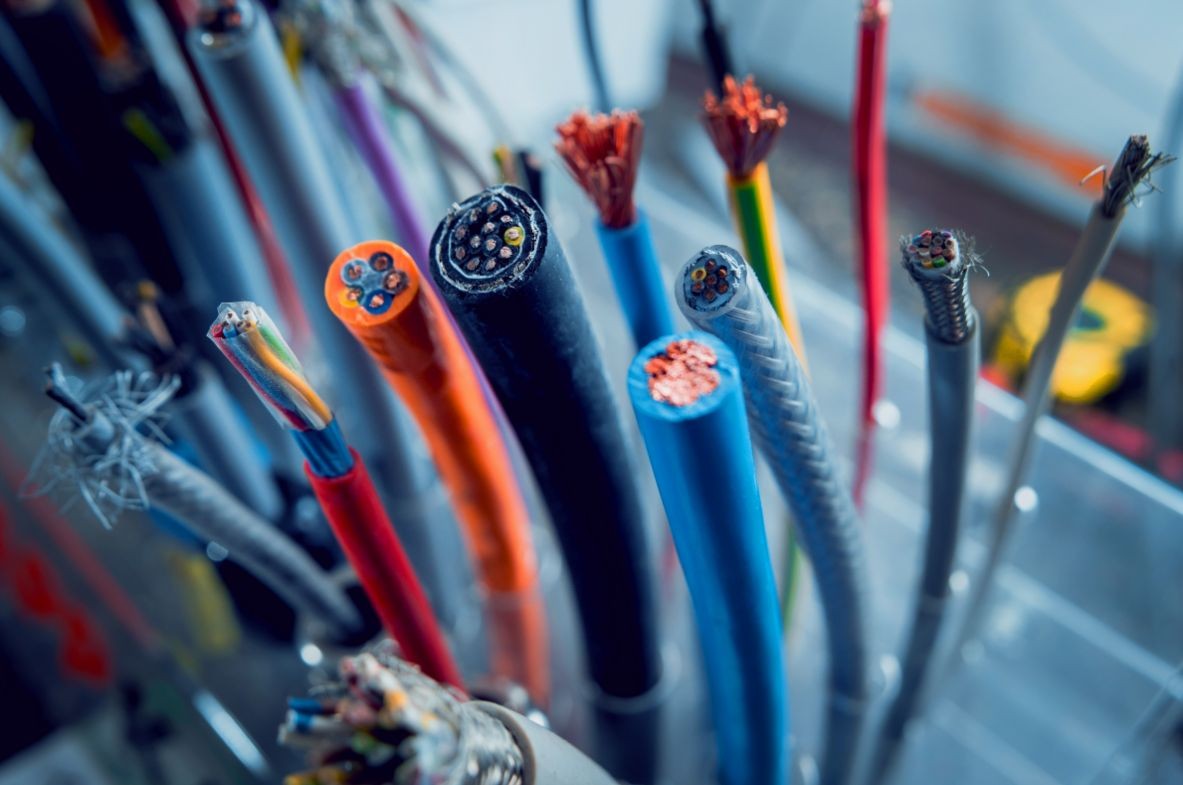

Have you ever wondered why machines suddenly stop working or communication systems face unexpected breakdowns? Many times, the problem lies in something as simple but crucial as a faulty signal control cable. These cables are responsible for carrying signals between devices, and if they fail, the whole system can come to a halt. The good news is that there are ways to identify early warning signs before they completely fail, saving you time, money, and unnecessary downtime.

Why It’s Important to Detect Cable Issues Early

Signal control cables are used in industries like manufacturing, automation, and communication to transfer signals accurately. Even a minor fault can lead to delays or safety risks. Detecting issues early helps avoid costly repairs and ensures that the equipment operates smoothly. A small preventive check today can save big headaches later.

Look for Visible Damage on the Cable

One of the easiest ways to identify a faulty signal control cable is to visually inspect it. Check for cuts, cracks, exposed wires, or any physical wear and tear. If the outer insulation is damaged, the internal wires may also be affected, which can cause signal interference or failure. Replace any cables that show physical damage immediately to prevent bigger issues.

Check for Loose or Damaged Connectors

Sometimes, the cable itself might be fine, but the problem lies with the connectors. If you notice that connections are wobbly or corroded, it’s a sign that maintenance is needed. Tighten or replace the connectors to ensure proper contact and stable signal transmission.

Watch for Signal Interference or Noise

A key sign of a failing signal control cable is unexpected signal interference or noise. This happens when the cable’s shielding is compromised or when there’s a break inside the wire. You may notice machines not responding correctly or communication systems delivering weak or unclear signals. Regular testing with diagnostic tools can help detect interference before the issue becomes critical.

Monitor for Overheating or Unusual Odors

Overheating could mean that the cable is overloaded, the insulation is breaking down, or there is an internal short circuit. Switch off the system immediately and replace the cable to avoid safety hazards like fire or equipment damage.

Check for Stiffness or Bending Problems

Signal control cables are meant to be flexible. If they suddenly become stiff or difficult to bend, it may be due to internal wire damage or insulation hardening over time. Stiff cables can break easily under stress and fail without warning. Replace any cables that lose their flexibility to maintain smooth operations.

Conduct Regular Electrical Testing

Visual inspection is helpful, but some problems are not visible to the naked eye. Periodic testing with a multimeter or continuity tester can help detect internal breaks or resistance changes inside the cable. Early detection of internal issues ensures that you replace faulty cables before they fail completely.

Pay Attention to Environmental Factors

These factors can speed up wear and tear. Make sure your cables are suitable for the environment in which they are used. For example, use cables with proper insulation for high-temperature areas or shielded cables where there’s a lot of electrical noise.

Train Your Staff to Spot Warning Signs

Sometimes cable issues go unnoticed simply because people don’t know what to look for. Train your team to identify early signs of cable failure, such as unusual machine behavior, loose connections, or visible wear. A proactive approach can prevent downtime and keep operations running smoothly.

Plan Regular Maintenance and Replacement

No cable lasts forever, no matter how high its quality. Have a maintenance schedule in place to regularly check and replace old cables. By replacing cables before they fail, you avoid sudden breakdowns and keep your systems safe and reliable.

Conclusion

Faulty signal control cables don’t fail overnight; they give warning signs. By regularly inspecting, testing, and maintaining them, you can prevent unexpected breakdowns and ensure safety and efficiency. if you take the time to identify these issues early, your machines and communication systems will thank you with uninterrupted performance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0