How MEP Shop Drawing Services Cut Errors and Slash Project Costs

Learn how MEP shop drawing services can significantly cut errors and lower project costs, enhancing efficiency and accuracy in your construction endeavors.

Construction projects face a staggering reality: mechanical, electrical, and plumbing (MEP) systems account for up to 40% of a building's total construction cost, yet they're also responsible for the majority of coordination conflicts and rework expenses. When MEP installations go wrong, the financial impact ripples through every aspect of a project—from extended timelines to costly material waste.

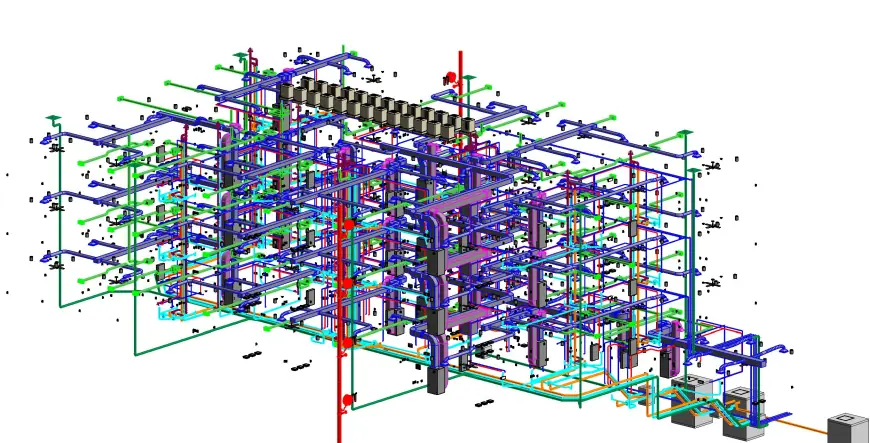

MEP shop drawing services have emerged as a critical solution to this challenge. These detailed technical drawings serve as the blueprint for fabricating and installing MEP components, bridging the gap between design intent and on-site reality. Professional MEP shop drawing services don't just translate architectural plans into actionable instructions; they actively prevent errors, streamline coordination, and deliver measurable cost savings.

For contractors, project managers, and building owners, understanding how these services work can mean the difference between a profitable project and a costly disaster.

Common Errors in MEP Projects and Their Financial Impact

MEP systems are inherently complex, involving intricate networks of ductwork, piping, electrical conduits, and equipment that must coexist within tight spatial constraints. Without precise coordination, several costly problems typically emerge.

Coordination conflicts represent the most expensive category of MEP errors. These occur when different trade systems—such as HVAC ducts and electrical conduits—occupy the same space, creating physical impossibilities during installation. A single major conflict can require days or weeks to resolve, involving redesign, material reordering, and schedule delays that cascade throughout the entire project.

Fabrication errors often stem from unclear or incomplete shop drawings. When fabricators work from inadequate documentation, they may produce components with incorrect dimensions, connections, or specifications. These errors typically aren't discovered until installation begins, requiring emergency fabrication of replacement parts and potentially delaying other trades.

Code compliance issues present another significant risk. MEP systems must meet numerous local, state, and federal regulations covering everything from fire safety to energy efficiency. Non-compliant installations can trigger expensive retrofits, project delays, and in severe cases, complete system replacement.

The National Institute of Standards and Technology estimates that inadequate interoperability and coordination in the construction industry costs $15.8 billion annually, with MEP systems contributing substantially to this figure.

How MEP Shop Drawing Services Minimize Errors

Accuracy and Precision

Professional MEP shop drawing services utilize advanced software and experienced technicians to create highly detailed, dimensionally accurate drawings. These services typically employ Building Information Modeling (BIM) technology, which creates three-dimensional models of all building systems with precise spatial relationships.

This level of detail eliminates guesswork during fabrication and installation. Every component is specified with exact dimensions, connection types, and material requirements. Fabricators receive clear instructions for creating parts that fit perfectly on the first attempt, while installers understand exactly how each component integrates with the overall system.

The precision extends beyond individual components to include comprehensive assembly details, connection specifications, and installation sequences. This thorough documentation reduces the likelihood of field modifications, which are typically more expensive and time-consuming than shop fabrication.

Coordination Between Disciplines

One of the most valuable aspects of professional MEP shop drawing services is their ability to coordinate multiple building systems within shared spaces. Using clash detection software, these services identify potential conflicts between mechanical, electrical, plumbing, fire protection, and structural elements before fabrication begins.

This coordination process involves more than simply avoiding physical conflicts. Professional services also optimize routing paths to minimize material usage, reduce installation complexity, and maintain required clearances for maintenance access. They consider factors such as pipe slopes, electrical code requirements, and HVAC performance criteria while developing coordinated solutions.

The result is a set of drawings that represents a fully coordinated MEP design, where every system has been planned to coexist efficiently with all others. This coordination eliminates the expensive discovery of conflicts during installation when resolution options are limited and costly.

Compliance with Standards

Professional MEP shop drawing services maintain current knowledge of applicable codes, standards, and regulations. This expertise ensures that all drawn systems comply with requirements such as the National Electrical Code, International Mechanical Code, and local amendments.

Compliance verification occurs throughout the drawing development process, not as an afterthought. This proactive approach prevents the costly discovery of code violations during inspection phases, when remediation options are limited and expensive.

Cost Savings with Professional MEP Shop Drawings

Reduced Rework and Delays

The most immediate cost benefit of professional MEP shop drawing services comes from eliminating rework and the schedule delays it causes. When installations proceed according to accurate, well-coordinated drawings, trades can work efficiently without waiting for conflict resolution or material replacement.

Project schedules become more predictable when MEP installations proceed smoothly. This predictability benefits all trades, as mechanical, electrical, and plumbing work often lies on the critical path for project completion. Delays in MEP installation typically extend overall project timelines, increasing general conditions costs and potentially triggering liquidated damages.

The elimination of emergency fabrication represents another significant savings. When shop drawings are accurate and complete, fabricators can produce all components during normal production schedules. Emergency orders, which can cost 50-100% more than standard fabrication, become unnecessary.

Efficient Installation Process

Well-prepared shop drawings enable MEP contractors to plan installation sequences more effectively, reducing labor costs through improved efficiency. Installers can work systematically through coordinated drawings rather than solving problems in the field, where limited space and time pressure increase costs.

Material waste decreases substantially when installations follow accurate shop drawings. Precise measurements and clear specifications prevent over-ordering, while coordination eliminates the need to modify or discard materials due to conflicts or errors.

Labor productivity improvements often exceed 20% when workers have access to clear, accurate installation drawings compared to projects relying on design drawings alone. This improvement reflects the difference between following detailed instructions and interpreting general design intent.

Long-Term Operational Savings

The benefits of professional MEP shop drawing services extend well beyond construction completion. Accurate as-built documentation, derived from shop drawings, provides building operators with precise information about system layouts, component specifications, and access points.

This documentation proves invaluable during maintenance activities, reducing the time required to locate components, identify replacement parts, and plan system modifications. Building operators report maintenance cost reductions of 15-25% when they have access to comprehensive MEP documentation.

Energy efficiency improvements also result from properly coordinated and installed MEP systems. When systems operate as designed, without field modifications or compromises, they typically achieve intended performance levels and energy consumption targets.

Investing in Quality MEP Shop Drawing Services

The construction industry increasingly recognizes that professional MEP shop drawing services represent essential project infrastructure rather than optional add-ons. The cost of these services—typically 1-3% of total MEP installation costs—generates returns that often exceed 300% through error prevention and efficiency improvements.

Successful project delivery depends on accurate information flow from design through installation. MEP shop drawing services provide the detailed, coordinated information that enables efficient construction while minimizing costly surprises and delays.

For contractors and project owners serious about controlling costs and schedules, professional MEP shop drawing services offer a proven path to improved project outcomes. The question isn't whether these services provide value—it's whether projects can afford the risks of proceeding without them.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0