How Additive Manufacturing Companies Are Revolutionizing Aerospace and Automotive Industries

Additive manufacturing, commonly known as 3D printing, has disrupted traditional production methods across various industries. Among its most impactful applications are in aerospace and automotive sectors, where precision, lightweight design, and customization are critical. Additive manufacturing companies are driving advancements in these fields, enabling faster production, reducing costs, and creating products that outperform those made with traditional techniques.

In this article, we’ll explore how additive manufacturing companies are revolutionizing aerospace and automotive industries, the challenges they face, and the future trends shaping these sectors.

The Role of Additive Manufacturing in Aerospace

The aerospace industry demands lightweight yet durable components that can withstand extreme conditions. Additive manufacturing companies have stepped up to meet these needs with technologies that improve design efficiency, reduce material waste, and accelerate production.

1. Lightweight Components

Aerospace manufacturers prioritize weight reduction to enhance fuel efficiency and reduce operational costs. Additive manufacturing creates intricate, optimized structures that traditional methods cannot achieve, leading to significant weight savings without compromising strength.

- Example: Additive manufacturing is used to create lattice structures in aircraft components, which are lighter yet equally robust.

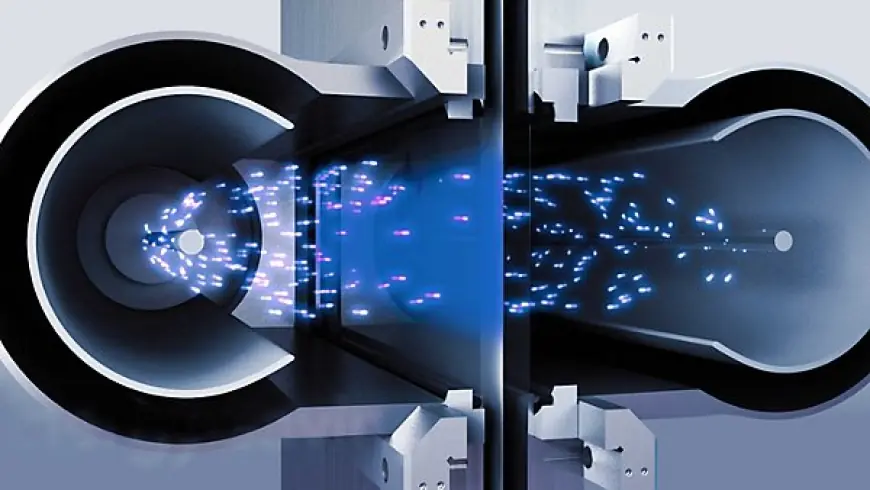

2. Complex Geometries

Traditional machining techniques struggle with producing complex geometries, especially for parts with internal channels or intricate designs. Additive manufacturing enables the creation of these geometries with ease, improving functionality and reducing assembly requirements.

- Example: Rocket nozzles and fuel injectors with optimized internal designs are manufactured using additive techniques, enhancing performance.

3. Reduction in Material Waste

The aerospace industry uses high-cost materials such as titanium and Inconel. Additive manufacturing companies minimize material waste by using only the necessary amount of material for production, saving costs and reducing environmental impact.

The Impact of Additive Manufacturing in Automotive

In the automotive sector, additive manufacturing supports both prototyping and production, offering benefits such as lightweight design, customization, and cost savings.

1. Rapid Prototyping

Automotive manufacturers rely on rapid prototyping to test and refine designs before full-scale production. Additive manufacturing companies enable faster turnaround times, allowing designers to iterate and improve products more efficiently.

- Example: Functional prototypes for engine components, brake systems, and aerodynamics testing are produced quickly using 3D printing.

2. Customization

As consumer demand for personalized vehicles grows, additive manufacturing facilitates mass customization. From custom interior trims to unique exterior designs, manufacturers can meet specific customer preferences cost-effectively.

- Example: Car manufacturers use additive manufacturing for customized dashboards, gear shifters, and ergonomic seating components.

3. Lightweight Design

Reducing vehicle weight improves fuel efficiency and performance. Additive manufacturing companies produce lightweight metal and composite parts that help automakers achieve these goals.

- Example: Lightweight suspension components and wheels manufactured using 3D printing contribute to better fuel economy.

4. On-Demand Spare Parts

Traditional spare parts inventory requires significant storage space and capital. Additive manufacturing companies enable on-demand production of spare parts, reducing inventory costs and ensuring faster delivery.

- Example: Automotive brands use additive techniques to create replacement parts for older models, reducing lead times.

Challenges Faced by Additive Manufacturing Companies in These Industries

While additive manufacturing offers numerous advantages, challenges remain, particularly in aerospace and automotive applications:

1. Material Limitations

The availability of high-performance materials for additive manufacturing is still limited. Expanding the range of materials that meet the strength, heat resistance, and durability requirements of these industries is essential.

2. Production Speed

Additive manufacturing processes are often slower than traditional mass-production methods, making it challenging to scale for high-volume applications.

3. Certification and Compliance

Aerospace components must meet stringent regulatory standards, and additive manufacturing processes require thorough validation to ensure safety and reliability.

4. Cost of Equipment

The initial cost of 3D printing equipment, particularly for metal additive manufacturing, can be prohibitive for smaller companies.

Innovations by Additive Manufacturing Companies

Additive manufacturing companies are addressing these challenges with innovative solutions:

Advanced Materials

New materials, such as carbon-fiber-reinforced composites and high-performance metal powders, are being developed to meet the demanding requirements of aerospace and automotive applications.

Hybrid Manufacturing

Combining additive manufacturing with traditional methods, such as CNC machining, allows companies to improve surface finishes and production speed.

Multi-Laser Printing

Technologies like multi-laser systems enable faster production, making additive manufacturing more viable for high-volume automotive applications.

Digital Twins

Digital twin technology allows manufacturers to simulate and optimize additive manufacturing processes, ensuring compliance with strict aerospace standards.

Future Trends in Additive Manufacturing for Aerospace and Automotive

1. Sustainability

As industries focus on reducing their carbon footprint, additive manufacturing’s ability to minimize material waste and energy consumption will become increasingly important.

2. Smart Manufacturing

The integration of additive manufacturing with Industry 4.0 technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), will improve production efficiency and quality control.

3. Large-Scale Printing

Advancements in additive manufacturing equipment will enable the production of larger components, expanding its applications in aerospace and automotive sectors.

4. Customization at Scale

The demand for personalized vehicles and aircraft interiors will drive further adoption of additive manufacturing for mass customization.

Leading Additive Manufacturing Companies in Aerospace and Automotive

Several companies are making significant contributions to these industries. For a comprehensive list of top additive manufacturing companies worldwide, visit https://ebeammachine.com/top-66-additive-engineering-companies-worldwide/.

Conclusion

Additive manufacturing companies are transforming aerospace and automotive industries with innovative solutions that enhance efficiency, reduce costs, and improve performance. By enabling lightweight designs, complex geometries, and on-demand production, these companies are setting new standards for manufacturing excellence.

As the technology continues to evolve, additive manufacturing will play an even more significant role in shaping the future of these industries. Whether it’s through advanced materials, hybrid manufacturing, or smart systems, the possibilities are endless. Explore the top additive manufacturing companies to discover how they can help your business stay ahead in this dynamic landscape.