Formwork Accessories Suppliers: Delivering Precision and Strength for Modern Construction

Working with trusted formwork accessories suppliers ensures your project benefits from safe, precise, and durable support systems. When combined with expertly designed steel custom made formwork, construction teams can achieve outstanding results, even in the most challenging projects.

In today’s fast-paced construction industry, efficiency, strength, and precision are crucial to delivering projects on time and within budget. One essential element that plays a vital role in shaping strong and accurate structures is the formwork system. While formwork itself is the foundation for shaping concrete, the performance and safety of the system depend heavily on the quality of its accessories. This is where trusted formwork accessories suppliers come into the picture, offering products designed to ensure stability, safety, and long-term reliability.

Among the leading names in this field, Biiformtek stands out for delivering top-notch solutions, including high-quality steel custom made formwork and a wide range of compatible accessories to meet the evolving needs of the construction sector.

Understanding the Role of Formwork Accessories

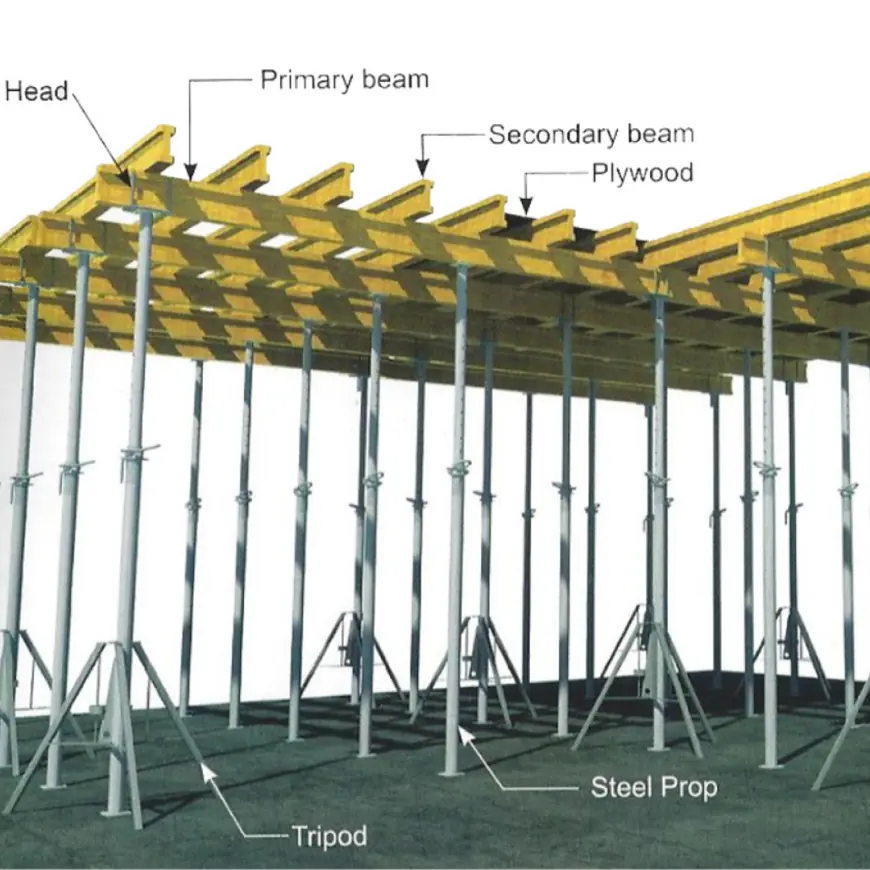

Formwork accessories are essential components that support and strengthen the formwork system during the concrete pouring and curing process. They ensure the correct alignment, maintain dimensional accuracy, and enhance the load-bearing capacity of the formwork. Without reliable accessories, even the best formwork panels can fail under the pressure of wet concrete.

Some of the most widely used formwork accessories include:

- Tie rods and wing nuts – For securing formwork panels together.

- Wedges and pins – To align and lock components in place.

- Couplers and clamps – For joining panels or structural elements.

- Adjustable props and jacks – To provide vertical support.

- Spacer tubes and washers – To maintain uniform spacing and prevent deformation.

Reliable formwork accessories suppliers ensure that each of these components is manufactured with precision and adheres to safety standards.

Importance of Choosing the Right Formwork Accessories Suppliers

Not all suppliers offer the same level of quality, durability, or service. Choosing the right partner for your construction project can make a significant difference in terms of performance, cost efficiency, and safety. Key factors to consider include:

- Quality Standards – Products should meet international safety and performance standards.

- Material Selection – High-grade steel and other durable materials ensure longer service life.

- Customization Options – Ability to provide steel custom made formwork or accessories tailored to unique project requirements.

- Technical Expertise – Suppliers who understand the challenges of modern construction can recommend the best solutions.

- Timely Delivery – Delays in accessories can lead to costly project slowdowns.

When you work with trusted suppliers like Biiformtek, you get more than just products—you gain a partner who is committed to your project’s success.

Steel Custom Made Formwork: A Game-Changer for Construction

While standard formwork systems meet the needs of many projects, complex designs and unique architectural features often demand steel custom made formwork. This specialized solution is designed and fabricated to match exact project specifications, ensuring perfect alignment, load-bearing capacity, and reusability.

Advantages of Steel Custom Made Formwork:

- Strength and Durability – Steel withstands high loads and resists wear, making it ideal for repeated use.

- Precision – Custom designs ensure accurate dimensions and a superior concrete finish.

- Versatility – Suitable for complex shapes, curves, and non-standard dimensions.

- Long-Term Value – While the initial investment may be higher, the durability of steel reduces long-term costs.

Biiformtek’s expertise in manufacturing steel custom made formwork allows construction companies to achieve high-quality results even in challenging builds.

Applications of Formwork Accessories and Custom Formwork

The combination of robust accessories and steel custom made formwork is used across a variety of construction projects, including:

- High-Rise Buildings – For core walls, columns, and slabs requiring precision and strength.

- Bridges and Flyovers – Heavy-duty systems to handle complex geometries and loads.

- Industrial Structures – Factories, plants, and warehouses where durability is essential.

- Infrastructure Projects – Tunnels, dams, and retaining walls requiring specialized support.

Whether it’s for vertical, horizontal, or curved structures, having the right accessories ensures stability and safety during every stage of construction.

The Biiformtek Advantage in Formwork Accessories Supply

As one of the leading formwork accessories suppliers in India, Biiformtek has built a reputation for delivering high-quality, reliable, and innovative solutions for the construction industry.

1. Comprehensive Product Range

From tie rods to wing nuts, clamps, wedges, and scaffolding accessories, Biiformtek provides everything needed to support your formwork systems.

2. Custom Manufacturing

Their steel custom made formwork services cater to unique project demands, ensuring exact fit and optimal performance.

3. Quality Commitment

Every product undergoes strict quality checks to ensure it meets industry standards for safety and performance.

4. Expert Guidance

Biiformtek’s technical team helps clients choose the most suitable accessories based on project requirements, saving both time and costs.

5. Timely Deliveries

With efficient logistics, Biiformtek ensures that accessories and formwork systems reach the site on schedule, preventing project delays.

How the Right Accessories Improve Project Outcomes

Using high-quality formwork accessories from a trusted supplier has a direct impact on project success. Some benefits include:

- Enhanced Safety – Strong, reliable accessories prevent failures and accidents on-site.

- Better Concrete Finish – Correct alignment and secure positioning reduce defects and rework.

- Faster Construction – Easy-to-install accessories speed up assembly and dismantling.

- Cost Savings – Durable components reduce replacement frequency and maintenance costs.

These factors make accessories a crucial investment rather than a mere expense.

Trends in Formwork Accessories and Custom Formwork

The construction industry is evolving rapidly, and formwork accessories suppliers are keeping pace with new trends, including:

- Lightweight yet Strong Materials – Development of accessories using high-strength alloys to improve handling without compromising durability.

- Eco-Friendly Coatings – Use of corrosion-resistant, non-toxic coatings to extend lifespan and reduce environmental impact.

- Modular Systems – Accessories compatible with multiple formwork types for versatility.

- Precision Engineering – Integration of advanced fabrication techniques like CNC machining for superior accuracy in steel custom made formwork.

By embracing these innovations, suppliers like Biiformtek help construction companies stay competitive and efficient.

Conclusion

The quality and reliability of formwork systems largely depend on the accessories that hold them together. Working with trusted formwork accessories suppliers ensures your project benefits from safe, precise, and durable support systems. When combined with expertly designed steel custom made formwork, construction teams can achieve outstanding results, even in the most challenging projects.

Biiformtek delivers on all fronts—quality, customization, timely delivery, and expert support—making them a preferred partner for construction companies across India. By investing in the right accessories and formwork solutions, you not only enhance efficiency and safety but also secure the long-term success of your projects.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0