Efficient Coalescing Plate Oil Water Separators for Industrial Use

Plate coalescing oil water separator function by directing the oil water mixture through a series of inclined plates. The design and positioning of these plates allow for the separation process to occur more rapidly and efficiently, making this a preferred method for many industries.

Oil Water Separators (OWS) are vital tools used in industrial processes that allow the mixture of oil and water to be separated. This is made possible because oil and water have differing densities and subsequently, will naturally separate when left undisturbed for enough time. These separators leverage this principle to quicken the process and make it both more efficient and effective.

The Importance of Efficient Oil Water Separation in Industries

Efficient oil water separation holds significant relevance in industries to ensure that water is purified from oil before it's released back into the environment. This process is key to reducing pollution, enhancing the sustainability of industrial practices, and adhering to environmental regulations. Not only is clean water essential for preserving the world's ecosystems, but efficiently removing oil also allows for it to be recycled and reused, further promoting sustainable industrial practice.

Understanding Plate Coalescing Oil Water Separators

Principle Behind Their Operation

To break it down simply, plate coalescing oil water separator function by directing the oil water mixture through a series of inclined plates. The design and positioning of these plates allow for the separation process to occur more rapidly and efficiently, making this a preferred method for many industries.

The Coalescing Process

Coalescing, in this context, refers to the process by which small droplets of oil merge into larger ones once they simultaneously meet the plates during separation. These larger oil droplets rise to the surface more rapidly due to their increased buoyancy, speeding up the separation process.

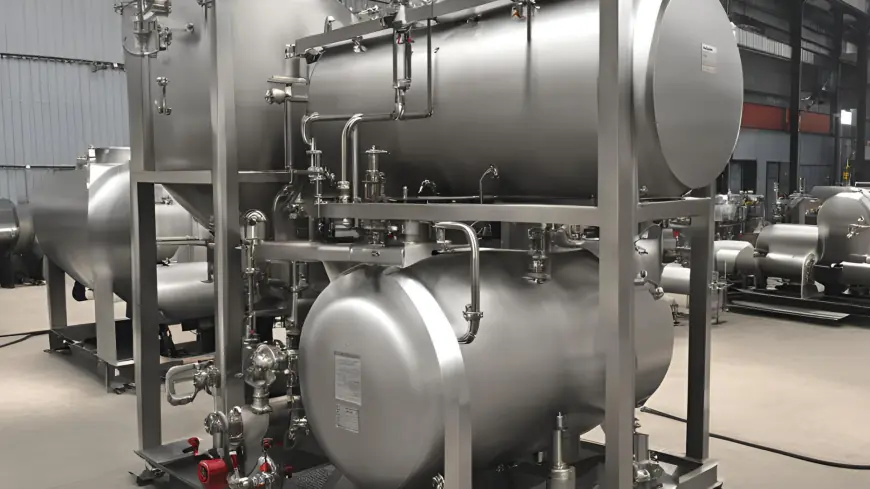

Key Components of Coalescing Plate Separators

Essentially, coalescing plate separators consist of several primary components. These include the inlet for the oil water mixture, the inclined coalescing plates, the oil collection chamber, the clean water outlet, and often, the sludge removal system. Each one of these components plays a crucial role in ensuring the effective separation of oil and water.

Types of Oil Water Separators

Understanding the different types of oil water separators helps customize the solution to the specific needs of an industry. Primarily, there are four types: API (American Petroleum Institute) separators, CPI (Corrugated Plate Interceptor) separators, IGF (Induced Gas Flotation) separators, and TPI (Tilted Plate Interceptor) separators.

Each separator operates slightly differently and has its advantages; efficiently separating oil from water and catering to various industrial needs. While API separators are the simplest and most used, CPI, IGF, and TPI separators offer more advanced features like flotation cell technology and improved oil removal rates, and inclined plate technology respectively.

How to Choose the Right Oil Water Separator for Your Industry

Choosing an oil water separator requires thorough research based on the volume and type of waste needing to be separated, the size constraints of the location, compliance regulations, as well as your budgetary restrictions. It's critical to also consider the ease of maintenance and potential for upgrades or improvements down the track.

Functional Efficiency of Plate Coalescing Oil Water Separators

Efficiency Metrics to Consider

When evaluating the Functional Efficiency of the plate coalescing oil water separators, it is imperative to consider important performance metrics. This includes the separator's oil removal rate, suspended solid extraction efficiency, its total dynamic head, the size of the separator relative to the flow rate, and the separator's oil retention time.

Importance of Proper Installation and Maintenance

Proper installation and routine maintenance are key to the optimal performance of plate coalescing oil water separators. These measures ensure the system's lifespan is maximized while ensuring consistent operational efficiency.

Reducing Environmental Impact with Efficient Separators

What an Effective Oil Water Separators Minimise Industrial Waste

Effective oil water separators play an essential role in minimizing industrial waste. They allow industries to efficiently separate oil from water, thus minimizing the volume of wastewater that needs treatment before discharge. Moreover, by effectively removing oil, these separators ensure that it can be recycled and reused rather than being discarded.

The Role of Separators in Adhering to Environmental Regulations

In most regions, there are stringent environmental regulations concerning the discharge of industrial wastes. Plate coalescing oil water separators are central to ensuring that these regulations are adhered to, as they efficiently separate oil and water, enabling the compliant disposal of industrial waste.

A Comprehensive Guide to Buying the Right Oil Water Separator

Factors to Consider When Choosing Your Separator

When deciding on an oil water separator for your business, it's crucial to consider several factors. First and foremost, you need to consider the application for which the separator will be used - different sectors have different requirements and thus require different types of separators. Additionally, the amount of oil waste produced, the space available for the separator, and the budget are also important considerations.

Common Errors to Avoid When Purchasing Separators

There are a few common mistakes one should avoid when purchasing an oil water separator. These include choosing the wrong type of separator for the specific application, neglecting the importance of regular maintenance, and prioritizing price over quality and efficiency.

Expert Recommendations on Brands and Models

While countless brands offer oil water separators, some standout companies are setting industry standards. Brands such as Aqua Safety Systems, Alfa Laval, and F.A Maker have a broad range of models appreciated for their advanced technologies, impressive longevity and top-notch customer support.

The Future of Oil Water Separator Technology

Emerging Technologies and Innovations

The field of oil water separator technology is rapidly evolving. New technologies and improvements to existing systems aim to make separators even more efficient. For example, the development of compact flotation units (CFU) which utilize gas bubbles to increase the speed at which oil rises to the surface in the separation process.

How These Improvements Will Make Separators More Efficient

Technological advancements in this field are geared towards enhancing efficiency, reducing energy consumption, minimizing environmental impact, and reducing the cost of operation. As efficiencies increase, industries can expect to save considerable time, energy, and operating costs in the future.

Conclusion

Understanding the functioning and efficiency of coalescing plate oil water separator is fundamental to improving industrial processes. By maximizing the effectiveness of oil water separation, these devices promote a more sustainable, cost-effective, and regulation-compliant operation. Furthermore, mastering the operation and maintenance of these separators can optimize their longevity, further increasing their cost-effectiveness. In sum, the right knowledge and application of coalescing plate oil water separators can be a game-changer for numerous industries.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0