Copper C11000 Tubes: Properties, Applications, and Benefits

Copper has been a trusted material in industries for centuries due to its excellent thermal and electrical conductivity. Among its many grades, Copper C11000 Tubes stand out for their high purity, strength, and versatility. These tubes are widely used in power generation, heat exchangers, plumbing, and industrial applications. Their unmatched durability and efficiency make them a preferred choice for engineers and manufacturers across the world.

This blog explores the key properties, benefits, applications, and why C11000 Copper Tubes are an ideal solution for various industries.

What Are Copper C11000 Tubes?

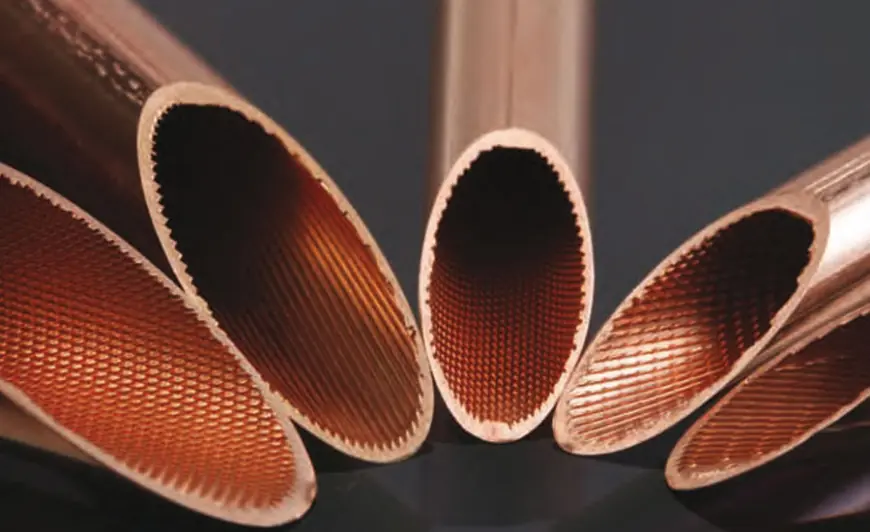

Copper C11000, also known as Electrolytic Tough Pitch (ETP) Copper, contains about 99.9% pure copper. This high-purity grade is recognized for its excellent electrical and thermal conductivity. Tubes manufactured from C11000 copper are seamless or welded, depending on the requirement.

The term “C11000” comes from the UNS designation, which classifies it as one of the most commonly used copper grades in tubes and pipes.

Key Properties of Copper C11000 Tubes

1. High Electrical Conductivity

C11000 copper tubes have an electrical conductivity of 100% IACS (International Annealed Copper Standard). This makes them ideal for power and electrical applications.

2. Excellent Thermal Conductivity

The tubes are highly efficient in conducting heat, which is why they are widely used in heat exchangers, condensers, and refrigeration systems.

3. Corrosion Resistance

C11000 tubes resist corrosion in water, steam, and most non-oxidizing environments, extending service life in plumbing and marine applications.

4. Mechanical Strength

These tubes offer good tensile strength and are easy to fabricate, bend, and weld.

5. Durability

With high resistance to wear and long-lasting performance, C11000 Copper Tubes reduce maintenance costs.

Manufacturing Standards

Copper C11000 Tubes are produced in accordance with various international standards:

-

ASTM B111

-

ASTM B280

-

BS EN 1057

-

JIS H3300

Manufacturers offer them in seamless and welded forms, with different dimensions, wall thicknesses, and finishes.

Applications of Copper C11000 Tubes

1. Electrical Applications

Due to their superior conductivity, C11000 copper tubes are widely used in power distribution systems, switchgear, and electrical conductors.

2. Heat Exchangers and Condensers

The excellent thermal conductivity makes these tubes essential for heat exchangers, refrigeration units, and HVAC systems.

3. Plumbing and Piping

They are used in plumbing lines, water distribution systems, and gas lines, thanks to their corrosion resistance.

4. Industrial Use

C11000 tubes are common in automotive, aerospace, petrochemical, and marine industries, where high performance is required.

5. Renewable Energy

In solar power plants, copper tubes help in heat transfer and cooling systems.

Benefits of Using Copper C11000 Tubes

-

High Conductivity: Ideal for efficient energy transfer.

-

Versatility: Suitable for both industrial and domestic use.

-

Corrosion Resistance: Long-lasting performance in different environments.

-

Easy Fabrication: Can be bent, shaped, and welded without losing strength.

-

Sustainability: Copper is fully recyclable without losing quality.

Why Choose Copper C11000 Tubes?

Industries choose C11000 copper tubes because they combine strength, reliability, and efficiency. Whether it is for conducting electricity, transferring heat, or carrying fluids, these tubes perform exceptionally well. Their long service life reduces replacement needs, making them cost-effective in the long run.

Maintenance Tips

-

Regular inspection for scaling or deposits in heat exchangers.

-

Use protective coatings in highly corrosive environments.

-

Ensure proper fittings to avoid leaks in plumbing systems.

Conclusion

Copper C11000 Tubes are an essential component in modern industries. Their superior conductivity, corrosion resistance, and durability make them a trusted material for electrical, thermal, and fluid systems. With the increasing demand for efficient and sustainable materials, C11000 tubes will continue to play a major role in industrial growth.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0