Brass vs. Bronze: The 2026 Engineering Guide to Avoiding Costly Alloy Mix-ups

Choosing between brass and bronze in 2026 is no longer as simple as picking "yellow vs. red." With over 30% of component failures in marine and industrial environments tracing back to incorrect alloy selection, getting this right is a financial necessity. This guide previews the latest 2026 material standards, provides proof of performance in high-stress environments, and highlights the key differences that will save your project from premature failure.

1. The Elemental Breakdown (Zinc vs. Tin)

The fundamental difference lies in the "partner" metal added to copper. Brass is primarily copper plus zinc, while bronze is copper plus tin (and often silicon or aluminum).

How to decide:

-

The Zinc Factor: Brass is more malleable and has a lower melting point, making it the king of intricate CNC machining and musical instruments.

-

The Tin Strength: Bronze is significantly harder and more brittle than brass. If your part needs to withstand heavy friction (like a sleeve bearing), bronze is your go-to.

-

Industry Pitfall: Beware of "lead-free" regulations in 2026; ensure your supplier provides updated material certifications for potable water applications.

Visual Suggestion: [Insert a side-by-side macro photo comparing the grain structure of machined Brass 360 vs. Phosphor Bronze.]

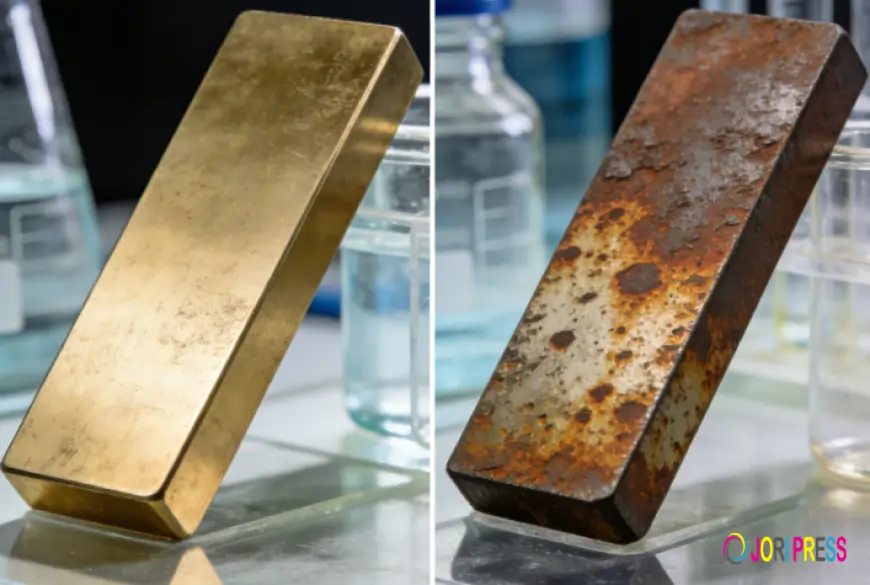

2. Corrosion Resistance: The Salt Spray Reality

If your project is headed for the coast, the choice is clear. Bronze develops a protective patina that shields it from salt water corrosion. Brass, however, is susceptible to "dezincification" in saline environments, where the zinc literally leaches out of the metal, leaving a porous, weak structure.

Pro Tip:

-

For marine hardware, always specify Aluminum Bronze or Silicon Bronze.

-

Avoid standard yellow brass for any component that will be submerged or exposed to heavy salt spray.

3. Machinability vs. Material Cost

In 2026, machining time is often more expensive than the raw material itself. Brass 360 remains the "gold standard" for high-speed CNC turning due to its incredible machinability. Bronze, being tougher, requires slower speeds and higher-quality carbide tooling.

Data Support: * Machining a complex part in bronze can take up to 40% longer than the same part in brass.

-

Calculate your ROI based on "Total Part Cost," not just the raw material price per pound.

Visual Suggestion: [Insert a comparison table showing Tool Wear Rates and Cycle Times for Brass vs. Bronze.]

Take the Next Step in Your Material Selection

Choosing the wrong copper alloy can lead to a nightmare of returns and field failures. The 2026 manufacturing landscape demands a deeper understanding of these ancient yet evolving metals.

To ensure your next project uses the optimal alloy for performance and budget, start by downloading a material compatibility chart. For a full breakdown of chemical compositions, mechanical properties, and 2026 industry applications, read our definitive guide:

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0