Bellow Seal Valves: Reliable Flow Control for Critical Power Generation Applications

find out all about Bellow Valves used across used in various industries handling critical application.

In industries where safety, efficiency, and zero leakage are non-negotiable, valve selection plays a decisive role in operational reliability. Among the many industrial valve designs available today, bellow seal valves stand out for their ability to deliver long-term, leak-free performance under extreme operating conditions. One of the major industries where these valves are extensively used is power generation, particularly in thermal and nuclear power plants.

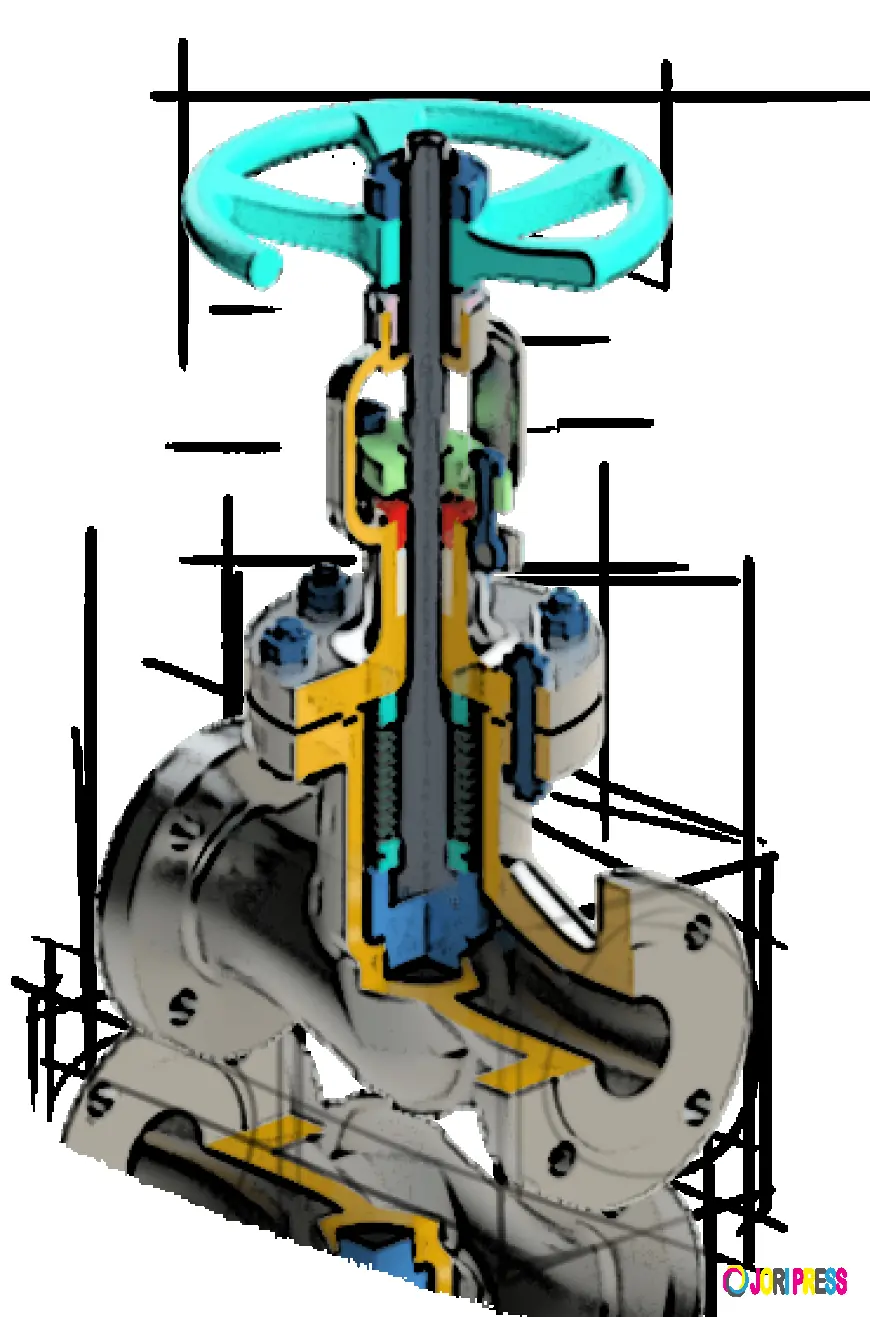

Understanding Bellow Seal Valves

A bellow seal valve is a type of globe or gate valve that uses a metallic bellows assembly to seal the stem. Unlike conventional packing-based valves, the bellows forms a hermetic seal between the valve stem and the body, preventing any process fluid from escaping to the atmosphere.

The bellows expands and contracts with the movement of the valve stem, eliminating stem leakage entirely. This design is especially critical when handling high-temperature, high-pressure, or hazardous media.

Why Power Generation Demands Bellow Seal Valves

Power plants operate under some of the most demanding conditions in any industrial environment. Systems routinely handle superheated steam, feed water, boiler chemicals, and thermal fluids, often at extreme temperatures and pressures. Even minor leakage in such systems can lead to efficiency losses, safety risks, and unplanned shutdowns.

Bellow seal valves address these challenges effectively, making them a preferred choice in power generation facilities.

Key Applications in Power Plants

1. Boiler Feed Water Systems

In boiler feed circuits, maintaining pressure integrity is crucial. Bellow seal valves prevent stem leakage, ensuring stable system pressure and protecting nearby equipment from thermal damage.

2. Superheated and Saturated Steam Lines

Steam leakage is not only an energy loss but also a serious safety hazard. Bellow seal valves provide a zero-emission sealing solution, making them ideal for main steam and auxiliary steam lines.

3. Condensate Systems

Condensate recovery systems require tight shut-off to maintain efficiency. Bellow seal valves ensure reliable isolation without frequent maintenance.

4. Chemical Dosing and Auxiliary Services

Power plants use various treatment chemicals for corrosion control and water conditioning. Bellow seal valves prevent chemical vapors or fluids from escaping, supporting safer working environments.

Technical Advantages of Bellow Seal Valves

Zero Stem Leakage

The primary advantage is the complete elimination of stem leakage, even after thousands of operating cycles.

High Temperature and Pressure Resistance

Metallic bellows are designed to withstand extreme thermal expansion and pressure fluctuations common in power plant operations.

Reduced Maintenance Requirements

Since there is no conventional gland packing to adjust or replace frequently, maintenance intervals are significantly extended.

Enhanced Safety and Environmental Compliance

By preventing fugitive emissions, bellow seal valves help power plants meet stringent safety and environmental regulations.

Long Service Life

The combination of robust valve construction and precision-engineered bellows ensures consistent performance over extended periods.

Materials and Design Considerations

For power generation applications, bellow seal valves are commonly manufactured using carbon steel, alloy steel, or stainless steel, depending on operating conditions. The bellows itself is typically made from high-grade stainless steel or special alloys to withstand cyclic stress and corrosion.

Many designs also include a secondary packing arrangement as a backup, providing additional safety in the unlikely event of bellows failure.

Future Role of Bellow Seal Valves in Power Plants

As power generation facilities move toward higher efficiencies and stricter emission controls, the demand for zero-leakage valve solutions continues to grow. Bellow seal valves align perfectly with these objectives by supporting safer operations, reducing energy losses, and minimizing environmental impact.

Whether in conventional thermal plants or advanced power generation systems, bellow seal valves remain a critical component in ensuring reliable and efficient flow control.

In the power generation industry, where operational reliability and safety are paramount, bellow seal valves offer a proven solution for controlling high-temperature and high-pressure fluids without leakage. Their robust design, low maintenance requirements, and compliance with modern safety standards make them indispensable for critical power plant applications.

By investing in high-quality bellow seal valves, power generation facilities can enhance system integrity, improve efficiency, and ensure long-term operational stability.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0