Artificial Intelligence in Supply Chain and Predictive Analytics AI: Powering Smarter, Resilient Operations

Artificial intelligence (AI) is no longer a futuristic concept in supply chain management — it’s a transformational force driving real business outcomes today. From demand forecasting and inventory optimization to risk detection and logistics planning, AI empowers organizations to become more agile, proactive, and resilient in an increasingly volatile global marketplace.

Artificial intelligence (AI) is no longer a futuristic concept in supply chain management — it’s a transformational force driving real business outcomes today. From demand forecasting and inventory optimization to risk detection and logistics planning, AI empowers organizations to become more agile, proactive, and resilient in an increasingly volatile global marketplace. Understanding how AI integrates with predictive analytics is central to unlocking these benefits.

As businesses seek to future-proof operations, tools that combine real-time data with advanced AI models are enabling better-informed decisions, sharper forecasting, and smarter automation. In this article, we’ll unpack how artificial intelligence in supply chain functions, why predictive analytics AI matters, and what this means for leaders striving to build more efficient and resilient networks.

What Does AI Mean for Modern Supply Chains?

In supply chain contexts, AI refers to the use of machine learning (ML), natural language processing (NLP), computer vision, and other intelligent algorithms to analyze data, recognize patterns, automate processes, and derive actionable insights. These systems go far beyond traditional analytics by learning from vast amounts of data and continuously improving predictions and recommendations.

AI technologies in the supply chain typically include:

- Machine learning (ML): Algorithms that identify patterns in historical and real-time data.

- Predictive analytics: Models that forecast future trends, demand shifts, and risk signals.

- Computer vision: Used for automated inspection and quality control.

- Automation and robotics: Systems that streamline repetitive tasks and improve efficiency.

Together, these technologies help organizations move from reactive problem-solving to proactive optimization.

Predictive Analytics AI: The Heart of Smarter Supply Chain Planning

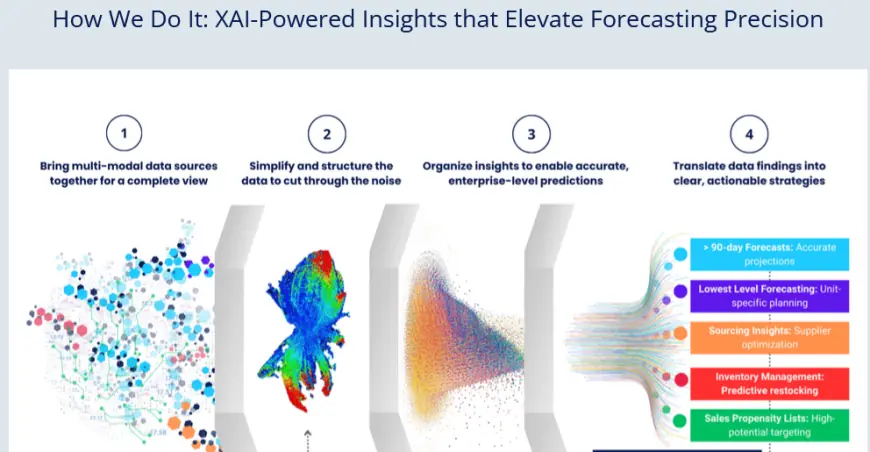

At the core of AI’s impact in the supply chain lies predictive analytics AI — the application of machine learning models to forecast future outcomes with remarkable precision. Unlike traditional forecasting methods, which often rely on historical averages and assumptions, AI-driven predictive analytics can:

- Analyze large datasets from multiple sources (e.g., sales history, market trends, weather patterns).

- Detect subtle patterns and correlations that human analysts might miss.

- Anticipate demand changes, inventory needs, logistics disruptions, and supplier issues.

For instance, businesses leveraging predictive analytics AI can optimize inventory levels by reducing both stockouts and excess inventory simultaneously — a balance that is notoriously difficult without advanced modeling. The result is not just smoother operations, but measurable cost savings and improved customer satisfaction.

Moreover, predictive analytics helps supply chain leaders anticipate risks, test multiple “what-if” scenarios, and evaluate the potential impact of market disruptions before they happen — enabling smarter contingency planning and response strategies.

Practical Applications of AI in Supply Chain

AI’s influence spans the entire supply chain ecosystem. Some of the most impactful applications include:

1. Demand Forecasting and Inventory Optimization

Predictive analytics models process historical sales data alongside external signals — like seasonality, promotions, and macro trends — to generate highly accurate demand forecasts. These predictions allow better inventory planning, helping companies avoid both shortages and overstocks.

2. Logistics and Transportation Planning

AI models can dynamically optimize transportation routes by factoring in real-time traffic, weather conditions, and carrier performance. This not only improves delivery speed but also reduces costs and environmental impact.

3. Predictive Maintenance

AI systems monitor sensor data from equipment and machinery to predict failures before they occur, preventing costly downtime and extending asset lifespan — a capability central to efficient supply chain operations.

4. Supply Chain Risk and Supplier Management

Predictive analytics can highlight supplier risk indicators — such as delayed shipments or financial instability — enabling companies to switch vendors, adjust sourcing strategies, or reallocate resources before problems escalate.

5. Automation and Intelligent Task Assistance

AI can automate time-intensive tasks like order processing, documentation generation, and reporting, freeing human teams to focus on strategic priorities. Generative AI and AI agents even help draft complex documents or simulate scenarios based on real supply chain data.

These practical applications are drawing increasing investment from supply chain leaders seeking not just efficiencies but sustainable competitive advantages.

Strategic Advantages of AI-Driven Predictive Analytics

Adopting AI and predictive analytics in supply chains delivers measurable business outcomes:

- Increased forecast accuracy: AI models significantly reduce forecast errors compared to traditional methods.

- Reduced operational costs: Optimization and automation lower logistics and inventory expenses.

- Improved risk management: Supply chain networks become more resilient to disruptions.

- Enhanced visibility: Real-time insights help manage operations more proactively.

These benefits are reshaping the way companies think about their planning horizons — transitioning from fixed annual forecasts to dynamic, data-driven strategies.

Challenges and Considerations

Despite its potential, integrating AI into supply chains isn’t without challenges. Data quality and accessibility often pose initial barriers, as AI models rely on comprehensive, clean datasets to perform effectively. Organizational readiness — including talent and infrastructure — can also influence how quickly AI initiatives deliver value. Addressing these challenges requires thoughtful data strategy, cross-functional collaboration, and iterative deployment.

Looking Ahead: The Future of AI in Supply Chains

As AI continues evolving, its role in supply chains will deepen. Emerging technologies like large language models (LLMs) and agentic AI — systems that can simulate, adapt, and enact decisions — are shifting the frontier of what’s possible. These advances promise even more autonomous and responsive networks that can self-optimize, anticipate disruption, and continuously learn from new data.

In this landscape, predictive analytics AI will remain a cornerstone: the engine that turns raw data into foresight and agility.

Conclusion

The integration of artificial intelligence in supply chain isn’t just a technical upgrade — it’s a strategic imperative. By embedding predictive analytics AI into planning, logistics, and risk management, companies unlock a powerful capability to anticipate change, optimize operations, and build resilience in a fast-paced global economy.

As organizations continue embracing intelligent technologies, those who harness AI for prediction and insight will be best positioned to navigate uncertainty and drive long-term growth.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0