Anodizing Services in Malaysia: Enhancing Durability and Aesthetics for Metal Products

At VG Steel, we specialize in high-quality anodizing services malaysia, offering advanced techniques to meet the diverse needs of our clients.

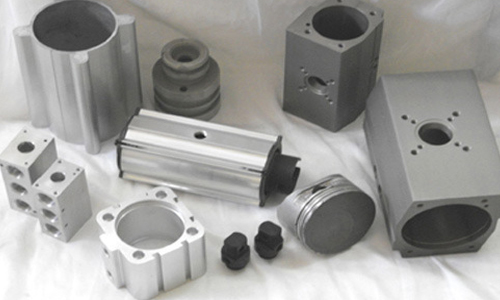

When it comes to enhancing the durability, corrosion resistance, and appearance of metal products, anodizing stands out as one of the most effective processes. In Malaysia, businesses across various industries are increasingly turning to anodizing services to improve the performance and lifespan of their metal parts and components. At VG Steel, we specialize in high-quality anodizing services, offering advanced techniques to meet the diverse needs of our clients.

What is Anodizing?

Anodizing services malaysia is an electrochemical process that enhances the natural oxide layer on metal surfaces, particularly aluminum. By immersing the metal in an acidic electrolyte bath and applying an electric current, the surface of the metal undergoes oxidation. This creates a thicker, more durable oxide layer, which offers increased resistance to corrosion, wear, and environmental damage. Not only does anodizing improve the functionality of metal products, but it also provides a unique opportunity to enhance their visual appeal through the addition of vibrant colors.

Why Choose Anodizing Services in Malaysia?

Anodizing Services Malaysia is a widely used process for a variety of reasons. Whether you're in the automotive, aerospace, construction, or manufacturing sectors, anodizing provides several advantages:

1. Increased Durability

The most significant benefit of anodizing is the enhanced durability it provides. The anodized layer is hard, resistant to scratching, and capable of withstanding harsh environmental conditions. For industries like aerospace and automotive, where metal parts are subjected to extreme temperatures and physical stress, anodizing ensures long-lasting performance.

2. Corrosion Resistance

In a country like Malaysia, where the climate can be hot and humid with occasional rainfall, corrosion can be a significant concern. Anodizing creates a protective barrier that prevents moisture and air from reaching the underlying metal, reducing the risk of rust and corrosion. This makes anodized metals ideal for use in outdoor and marine environments, where exposure to the elements is inevitable.

3. Aesthetic Appeal

Anodizing not only improves the functionality of metal but also enhances its appearance. The process allows metal surfaces to develop a unique matte or shiny finish, depending on the desired effect. Additionally, anodized metals can be dyed in a wide range of colors, offering endless possibilities for customization. Whether you're looking for a sleek, modern finish or a more vibrant, eye-catching look, anodizing services in Malaysia can deliver the aesthetic results you're after.

4. Environmentally Friendly

Anodizing is an environmentally friendly process. Unlike other surface treatments that use harmful chemicals or coatings, anodizing creates a naturally occurring oxide layer that is both durable and non-toxic. The process itself does not produce harmful emissions, making it a sustainable choice for businesses looking to reduce their environmental impact.

5. Low Maintenance

Anodized metal surfaces require minimal maintenance compared to uncoated or painted metals. The anodized layer is highly resistant to wear and tear, and because it is integrated into the metal surface, it won't peel or flake off like paint can. Regular cleaning is often all that's needed to keep anodized products looking like new.

How Anodizing Works: The Process Explained

At VG Steel, we employ advanced anodizing techniques to ensure the best possible results for our clients. Here’s a brief overview of the anodizing process:

-

Preparation: The metal surface is thoroughly cleaned to remove any dirt, oils, or impurities. This step is crucial for ensuring that the anodizing process adheres properly to the metal surface.

-

Anodizing: The metal is submerged in an electrolyte solution (usually sulfuric acid) and an electrical current is applied. The current causes the metal to form an oxide layer on the surface. The thickness of this layer can be controlled based on the time and voltage applied, allowing for customization of the final result.

-

Coloring (Optional): After anodizing, the metal can be dyed using organic or inorganic dyes. The porous oxide layer absorbs the dye, creating a vibrant and long-lasting color. The coloring can be customized to match specific brand aesthetics or functional needs.

-

Sealing: Once the anodizing and coloring are complete, the metal is sealed by immersing it in hot water or steam. This process closes the pores of the oxide layer, locking in the color and further increasing the durability of the surface.

-

Finishing: The final step involves finishing the metal surface to the desired texture, whether it’s a matte, satin, or high-gloss finish. This provides the metal with a polished look and further enhances its appearance.

Industries That Benefit from Anodizing Services in Malaysia

Anodizing Services is versatile and can be applied across a wide range of industries in Malaysia, offering both functional and aesthetic benefits. Here are some of the key sectors that rely on anodizing services:

1. Automotive Industry

The automotive sector requires high-performance materials that are resistant to wear, corrosion, and high temperatures. Anodizing aluminum parts, such as rims, grilles, and engine components, not only enhances their durability but also gives them a sleek, polished appearance.

2. Aerospace Industry

In the aerospace industry, anodized aluminum is widely used for aircraft components that need to endure extreme conditions. The corrosion resistance and lightweight nature of anodized aluminum make it an ideal choice for parts like landing gear, fuselage components, and interior elements.

3. Construction and Architecture

Architectural metalwork, including facades, railings, and window frames, often benefits from anodizing to provide both enhanced durability and an attractive finish. Anodized aluminum is highly resistant to weathering, making it perfect for outdoor applications.

4. Consumer Electronics

Anodizing is commonly used in the production of consumer electronics, such as smartphones, laptops, and home appliances. The process not only protects the metal components from corrosion and wear but also gives them a modern, high-tech appearance.

5. Marine and Outdoor Equipment

Given Malaysia’s tropical climate and proximity to the ocean, anodized metals are particularly well-suited for marine applications. Boat parts, outdoor furniture, and other marine equipment benefit from anodizing’s ability to prevent corrosion in salty environments.

Why Choose VG Steel for Anodizing Services in Malaysia?

At VG Steel, we pride ourselves on providing top-tier anodizing services tailored to meet the specific needs of our clients. With years of experience in the industry, we understand the importance of high-quality, durable finishes for metal products. Our state-of-the-art anodizing process ensures that each product we handle is given the best possible protection and aesthetic enhancement.

Whether you’re looking to improve the performance of your aluminum components or add a touch of style with custom colors, VG Steel is your trusted partner for anodizing services in Malaysia. Reach out to us today to discuss how we can help you achieve the perfect finish for your metal products!

Contact Us: [email protected]

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0