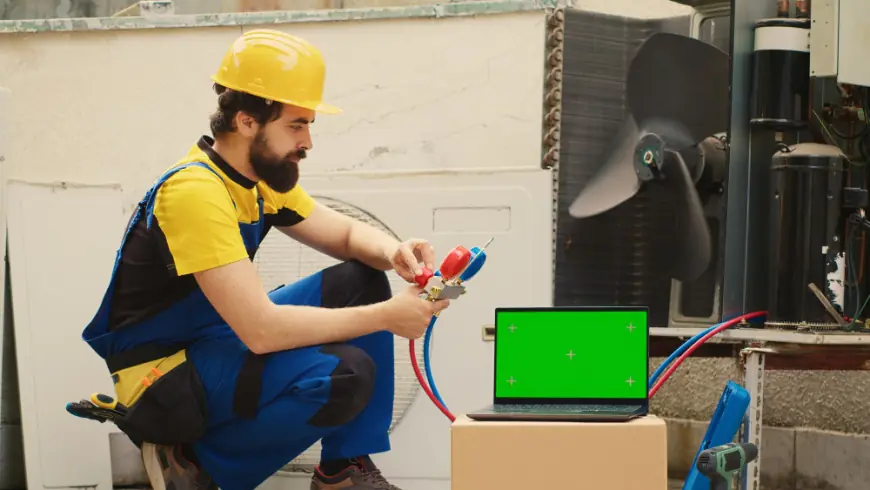

AC and DC Drives: Driving Performance Across Industries

Drives control motor behavior. They allow operators to control speeds and hold an accuracy value.

Modern industries require machines to be extremely efficient, precise, and reliable. And to enforce this, control systems take care of speed, torque, and power. Here come the AC and DC drives, which have considered indispensable across various sectors.

Drives control motor behavior. They allow operators to control speeds and hold an accuracy value. They save energy by consuming only so much power as needed for a certain task, thus becoming very handy in industries like manufacturing, transportation, and automation.

Flexibility is majorly one of the benefits. In the factory, machines need to run at speeds of variable magnitude. Instead of running at full power all the time, a drive ensures that the motors comply with exact demand, lowering wear and tear, resulting in longer life for the equipment, and, therefore, less cost.

In oil and gas, drives ensure safety and reliability. They operate pumps, compressors, and drilling equipment. By controlling power consumption, drives prevent sudden breakdowns and improve overall efficiency. Similarly, in water treatment plants, they maintain the stability of the process while optimizing energy consumption.

Drive systems serve the purpose of improving precision. In textiles, they control the precision of weaving and spinning machines while, in printing, they maintain alignment and speed. Such finer details witness the improvement of quality in output and reduction in wastage of finished material.

Another important benefit is the saving of energy. All industries worldwide are facing pressures to minimize carbon footprints. By using drives, less energy can be used by motors. Drives cut away unnecessary energy consumption without letting go of performance. In the long run, this translates to huge savings.

In transport systems, too, drives find use. Motor performance in electric trains, escalators, and conveyor belts has to be a controlled one. Drives aid in smooth functioning, comfort, and safety, and thus are crucial not only on the industrial side but in the usual public realm too.

Similarly, the presence of drives reduces the complexity of maintenance. The advanced models provide warnings of potential faults before they actually come up. By doing this, they reduce downtime and avoid expensive failures. Also, it allows the technician to resolve the fault faster and with greater precision.

In conclusion, drives are no longer optional for industries that seek progress. They form the very life of operations when it comes to reliability and sustainability. With further advances in technology, their direct role in shaping worldwide industries will certainly become quite significant.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0