Nanofibers: The Building Blocks for Revolutionary Materials and Technologies

Microfibers are fibers with diameters measuring only a few nanometers to a few hundred nanometers. Microfibers have extremely high surface-area-to-volume ratios and unique mechanical, optical, and chemical properties due to their nanoscale dimensions.

What are Microfibers?

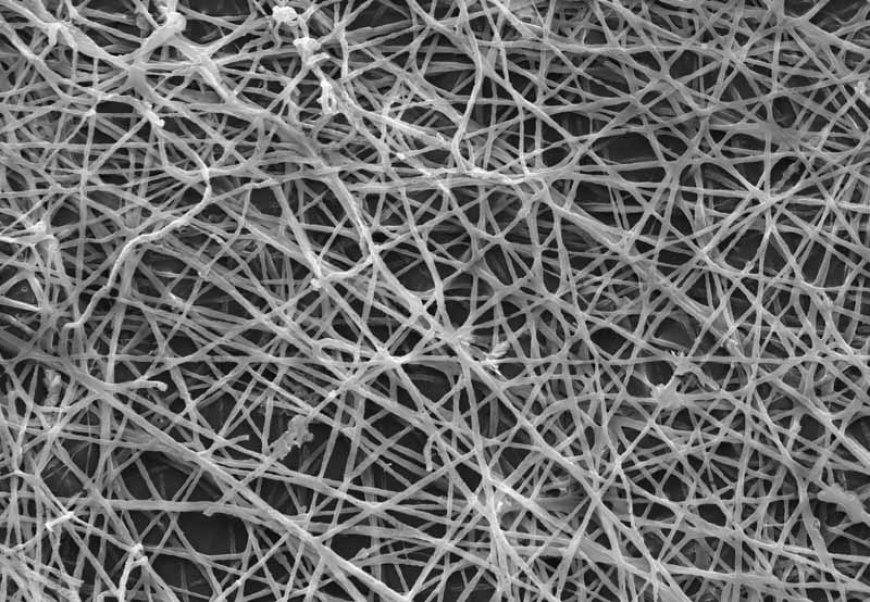

Microfibers are fibers with diameters measuring only a few nanometers to a few hundred nanometers. Microfibers have extremely high surface-area-to-volume ratios and unique mechanical, optical, and chemical properties due to their nanoscale dimensions.

Production Methods for Microfibers

There are various methods used for producing Microfibers, with electrospinning being the most common. In electrospinning, a high voltage electric field is used to draw Microfibers from a polymer solution or melt. As the polymer solution is injected through a spinneret, the electric charges in the solution overcome surface tension, causing the solution to stretch into very fine fibers that are deposited onto a collector. Other fabrication methods include self-assembly, drawing, template synthesis, phase separation, and solid-liquid interfacial polymerization.

Properties and Applications of Nanofibers

Due to their miniscule diameters and extremely high aspect ratios, Microfibers possess properties vastly different from thicker fibers. Microfibers have high surface area and pore volume, optical transparency, flexibility, and superior strength-to-weight ratios. These remarkable properties enable diverse Microfibers applications:

Filtration: Microfibers membranes are highly efficient for filtering submicron particles from air and liquids. Their small pore sizes can catch particles as small as viruses. Microfibers air filters are used in face masks, HVAC systems, and water purification.

Tissue Engineering: Microfibers scaffolds mimic the nanoarchitecture of collagen fibers in the natural extracellular matrix. They support cell adhesion, proliferation, and differentiation for growing artificial tissues. Microfibers-based organs and implants are being developed.

Catalysis: High surface area Microfibers provide great catalytic activity. Microfibers-supported catalysts require less precious metal loadings and offer unique shape selectivity. They find use as catalysts for fuel cells and in environmental remediation.

Sensing: Functionalized Microfibers are ideal for developing ultrasensitive chemical and biological sensors. Changes in fiber resistance, fluorescence, or mass can accurately detect analyte presence at very low concentrations.

Energy Devices: Nanofibers lead batteries store more energy and charge in thinner packages. As electrode materials in Li-ion batteries and supercapacitors, they boost energy and power densities. Piezoelectric Microfibers convert mechanical energy into electricity.

Challenges

As synthesis and processing techniques improve for tailoring Microfibers properties, their commercial use will expand dramatically. Self-assembly methods may enable mass production of complex 3D Microfibers structures. Continued miniaturization of Microfibers diameters could revolutionize existing technologies and unlock new applications not possible before. However, challenges remain regarding controlling fiber diameter dispersity, orientation, and interfiber bonding at industrial scales. Biocompatibility issues must also be addressed for in vivo Microfibers use. Overall, Microfibers hold immense promise as building blocks for next-generation materials with applications across numerous industries.

Microfibers in Biomedical Applications

Biodegradable Polymer Nanofibers for Tissue Engineering Scaffolds

Tissue engineering aims to regenerate functional tissues by seeding living cells onto 3D biomaterial scaffolds that facilitate new tissue growth. Microfibers fabricated from biodegradable polymers like collagen, gelatin, chitosan, and polycaprolactone mimic the nanoarchitecture of the native extracellular matrix and support cell adhesion, proliferation, and differentiation. Electrospun Microfibers scaffolds have interconnected porosity allowing for cell infiltration and nutrient/waste transport. Their high surface area also encourages desirable cell-matrix interactions critical for tissue regeneration. So far, Microfibers scaffolds have shown promise for engineering skin, blood vessels, bone, cartilage, and load-bearing musculoskeletal tissues.

Antibacterial Nanofibers for Wound Dressings

Chronic, non-healing wounds create enormous patient suffering and healthcare costs worldwide. Traditional wound dressings fail to prevent bacterial infection, delaying wound closure. Silver nanoparticle-loaded electrospun Microfibers offer a promising alternative, as the silver's contact killing ability and Microfibers's high surface area provide maximized antibacterial effects. Moreover, Microfibers dressings maintain a moist wound environment and absorb exudate efficiently while preventing ingress of external contaminants. Clinical studies demonstrate quicker healing times and reduced infection recurrence with Microfibers wound dressings compared to conventional dressings.

DDS-Loaded Microfibers for Sustained Drug Delivery

Successful drug delivery depends upon maintaining therapeutic drug levels for prolonged periods without surges or drops. Biodegradable polymer Microfibers loaded with medicines serve as personalized drug depots that degrade predictably. This ensures steady, controlled release of drugs over weeks to months for chronic conditions. Antibiotics, anticancer drugs, insulin and other biologics have all been successfully encapsulated within and released from Microfibers targeted to specific tissues. Implanted or injected Microfibers systems could transform treatment compliance for many diseases by eliminating multiple daily doses. However, sustained release profiles must be accurately tailored and biocompatible degradation controlled.

Nanofibers in Protective Textiles and Filtration Applications

Cut-Resistant Microfibers Gloves

Workplace injuries to hands remain pervasive despite gloves. Electrospun ultrahigh molecular weight polyethylene (UHMWPE) Microfibers mats just 150-200 nm thick yet stronger than steel alloy exhibit cut-resistance far surpassing traditional gloves.

Get more insights on Nanofibers

For Deeper Insights, Find the Report in the Language that You want

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)