7 Key Benefits of Pickling and Passivation for Stainless Steel Longevity

Discover 7 key benefits of pickling and passivation for stainless steel longevity, including corrosion resistance, cost savings, and compliance.

Stainless steel is widely known for its durability and resistance to corrosion, but even the toughest materials need protection to maintain their performance over time. Pickling and passivation are two essential surface treatment processes that help extend the life of stainless steel, making them indispensable in industries such as oil & gas, food processing, construction, and chemical manufacturing.

In this article, we’ll explore what these processes entail and discuss the 7 key benefits of pickling and passivation that contribute to stainless steel’s long-term reliability.

What Are Pickling and Passivation?

Before diving into the benefits, it’s important to understand these processes:

-

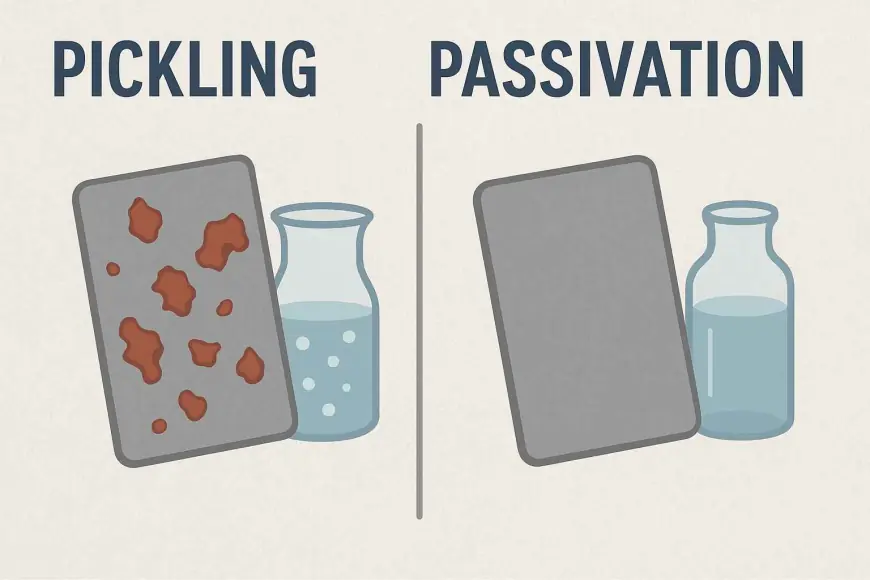

Pickling: This involves using an acid solution to remove impurities like rust, scale, and welding residues from stainless steel surfaces. It restores the material’s clean and reactive surface.

-

Passivation: After pickling, the metal undergoes passivation, where an acid treatment promotes the formation of a thin, protective chromium oxide layer. This passive layer serves as a shield against corrosion.

Together, pickling and passivation enhance the steel’s surface quality, ensuring it performs effectively in harsh environments.

1. Enhanced Corrosion Resistance

The primary benefit of pickling and passivation is improved corrosion resistance. Welding, fabrication, and environmental exposure can leave stainless steel vulnerable to rust and pitting. By removing contaminants and forming a passive oxide layer, these treatments significantly reduce the risk of corrosion, making the steel more reliable in challenging applications.

2. Extended Service Life

Corrosion is the leading cause of premature equipment failure. With proper pickling and passivation, stainless steel components can last for decades without significant deterioration. This not only saves costs on replacements but also minimizes downtime in industrial operations, which is crucial for sectors like petrochemicals and construction.

3. Improved Surface Cleanliness and Appearance

A clean, smooth surface is not just about aesthetics; it also prevents microbial contamination in industries like food and pharmaceuticals. Pickling removes weld scales, heat tints, and iron contaminants, leaving a uniform surface finish. Passivation enhances this smoothness and provides a consistent, polished appearance that meets hygiene and quality standards.

4. Compliance with Industry Standards

Many industries have stringent quality and safety standards that require stainless steel components to undergo pickling and passivation. For example, ASTM A967 and ASTM A380 outline specific requirements for passivated stainless steel. Ensuring compliance through these processes helps companies meet certification requirements, pass inspections, and maintain credibility in competitive markets.

5. Better Weld Integrity and Durability

Welded joints are particularly susceptible to corrosion and contamination. Pickling dissolves heat-affected impurities around weld areas, while passivation strengthens the protective layer over these vulnerable spots. As a result, welds become more durable and less prone to failure, which is critical for structural stability and safety.

6. Reduced Maintenance Costs

Investing in pickling and passivation upfront helps reduce long-term maintenance expenses. Since the steel’s surface becomes more resistant to rust and contamination, the need for frequent cleaning, repairs, or recoating is greatly minimized. For industries with large-scale stainless steel installations, this translates into substantial operational savings over time.

7. Environmentally Friendly Process

Unlike some protective coatings, pickling and passivation are environmentally safer when carried out properly. These processes do not add foreign materials to the surface but rather restore and enhance the metal’s natural corrosion resistance. Moreover, many service providers use eco-friendly solutions and proper waste treatment methods, ensuring sustainability and regulatory compliance.

Best Practices for Pickling and Passivation

To fully reap the benefits of these processes:

-

Always follow the manufacturer’s guidelines and industry standards.

-

Use qualified service providers who employ environmentally safe chemicals and proper disposal methods.

-

Perform routine inspections of stainless steel components to determine when treatment is necessary.

Why Pickling and Passivation Are Essential for Stainless Steel Longevity

The pickling and passivation process is not just an optional treatment; it’s a critical investment for anyone relying on stainless steel. Whether you operate in the food industry, marine environments, or high-temperature industrial settings, these treatments ensure your equipment and structures maintain optimal performance for years.

Conclusion: Invest in Stainless Steel Longevity Today

The 7 benefits of pickling and passivation—from enhanced corrosion resistance to reduced maintenance costs—make it clear why these processes are indispensable. By incorporating them into your maintenance strategy, you not only protect your investment but also boost operational efficiency and compliance.

If you’re looking to optimize your stainless steel equipment and ensure seamless operations, partner with experts who understand your industry needs. Additionally, sourcing high-quality maintenance products is crucial. For reliable solutions, reach out to leading lubricants suppliers in UAE, who can provide the right products and guidance to enhance equipment life and performance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0