3D Printing Automotive Market Competitive Benchmarking and Market Share 2025-2032

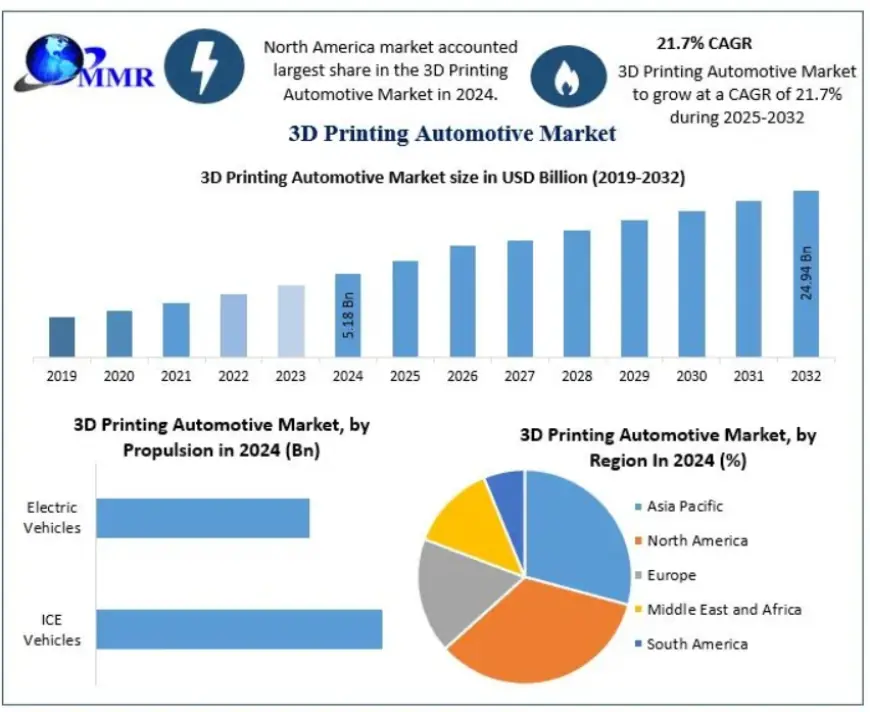

The 3D Printing Automotive Market size was valued at USD 5.18 Billion in 2024 and the total 3D Printing Automotive revenue is expected to grow at a CAGR of 21.7% from 2025 to 2032, reaching nearly USD 24.94 Billion.

3D Printing Automotive Market 2025-2032: Revolutionizing Automotive Manufacturing

The 3D Printing Automotive Market was valued at USD 5.18 billion in 2024 and is projected to reach USD 24.94 billion by 2032, growing at an impressive CAGR of 21.7% from 2025 to 2032. The growth of this market is driven by technological advancements, increasing adoption of electric vehicles, and rising demand for cost-efficient prototyping and manufacturing.

Market Overview

3D printing in the automotive sector, also known as additive manufacturing, is transforming traditional car manufacturing processes. Industrial 3D printing software allows efficient design, prototyping, testing, and production of automotive components. This technology reduces lead times, enhances design flexibility, lowers manufacturing costs, and allows for the production of complex, lightweight parts that are difficult to achieve through conventional methods.

Automakers are increasingly incorporating 3D printing into their R&D, prototyping, and end-part production, which is reshaping the automotive supply chain. OEMs such as Stratasys, 3D Systems, and EOS are leading this revolution by heavily investing in research, development, and production-ready additive manufacturing solutions.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/9760/

Market Drivers

- OEM Investments in 3D Printing:

Leading automotive manufacturers are investing heavily in 3D printing to reduce costs, speed up production, and improve customization. By integrating additive manufacturing into the production process, OEMs can produce parts faster and more efficiently. - Technological Advancements:

Innovations in 3D printing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Electron Beam Melting (EBM), and Fused Deposition Modeling (FDM), are enhancing precision, material versatility, and surface finish quality, enabling wider adoption in automotive manufacturing. - Prototyping and Tooling Efficiency:

Rapid prototyping is the largest application segment, enabling quick iterations, design changes, and cost-effective development. 3D printing reduces waste and accelerates the transition from concept to final part production. - Expansion of Electric Vehicles (EVs):

The rise of EV production increases demand for custom, lightweight, and high-performance components, further driving the adoption of additive manufacturing.

Market Challenges

Despite its growth, 3D printing in automotive manufacturing faces technological and economic barriers:

- Mass Production Limitations: Current 3D printers struggle with large-scale production of parts beyond 30 cm².

- Material Constraints: Most printers cannot mix multiple materials in a single component, although research is ongoing.

- High Costs: Metal powders and high-precision printers remain expensive, although costs are expected to decline with technological advancements.

Market Opportunities

The market has untapped potential in direct digital manufacturing (DDM) for complex automotive components, expanding beyond prototyping to functional end-use parts. Innovations in software, materials, and printing technologies are opening new applications in automotive, aerospace, and other industries.

Segment Analysis

By Application:

- Prototyping & Tooling: Largest segment due to cost-effectiveness, flexibility, and faster lead times.

- R&D & Innovation: Focused on developing advanced materials and innovative designs.

- Manufacturing Complex Components: Growing demand for precision-engineered and lightweight parts.

By Technology:

- Stereolithography (SLA): Dominates due to high precision and smooth surface finish.

- Selective Laser Sintering (SLS), Electron Beam Melting (EBM), Fused Deposition Modeling (FDM), and others provide versatility for different applications.

By Propulsion Type:

- Internal Combustion Engine (ICE) Vehicles: Traditional automotive segment adopting 3D printing for prototyping and components.

- Electric Vehicles (EVs): Driving adoption of lightweight, high-performance, and complex parts.

Regional Insights

- North America: Largest market in 2024, driven by continuous technological advancements and the presence of numerous car manufacturers. The United States dominates plastic 3D printing for interior components, dashboards, and trims.

- Europe: Fastest-growing market, with extensive use of additive manufacturing in R&D and production by leading automotive OEMs.

- Asia Pacific: Rapidly expanding, with emerging investments in EVs and automotive 3D printing technologies.

- Middle East & Africa and South America: Moderate growth, primarily in R&D and prototyping applications.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/9760/

Key Players

Prominent companies leading the automotive 3D printing market include:

- 3D Systems Corporation (US)

- Stratasys Inc. (Israel)

- EOS GmbH (Germany)

- Materialise NV (Belgium)

- Arcam AB (Sweden)

- Desktop Metal, Inc. (US)

- Concept Laser (Germany)

- Ultimaker BV (Netherlands)

- Ponoko Ltd (US)

- Chizel Prints Manufacturing Pvt. Ltd (India)

These players are investing in new product development, expansion, mergers, and joint ventures to strengthen their position in the market.

Future Outlook

The 3D Printing Automotive Market is set to grow exponentially through 2032, driven by:

- Rising adoption of additive manufacturing in EVs

- Technological advancements in 3D printing hardware and software

- Cost reductions and improved material efficiency

- Expansion of complex component manufacturing for both prototyping and end-use

With its potential to revolutionize automotive manufacturing, 3D printing is expected to become an integral part of OEM production strategies, enabling faster development, reduced costs, and enhanced customization.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0