Zinc Borate Production Process with Cost Analysis

Zinc Borate is a versatile compound used in various industries, including flame retardants, ceramics, and paints. Its production process involves a series of chemical reactions and careful quality control to ensure its efficacy in different applications.

Introduction

Zinc Borate is a versatile compound used in various industries, including flame retardants, ceramics, and paints. Its production process involves a series of chemical reactions and careful quality control to ensure its efficacy in different applications. Understanding the Zinc Borate production process and associated costs is essential for manufacturers looking to optimize their operations. This report provides a comprehensive analysis of the Zinc Borate production process, focusing on procurement resource assessment, market drivers, raw material requirements, and cost considerations.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/zinc-borate/request-sample

Procurement Resource Assessment for Zinc Borate Production

Effective procurement resource assessment is critical in the Zinc Borate production process. It involves sourcing high-quality raw materials, selecting reliable suppliers, and optimizing the supply chain to ensure uninterrupted production. Proper procurement strategies not only reduce costs but also enhance the overall efficiency and quality of the final product.

Key Factors

-

Supplier Selection: Identifying and partnering with reputable suppliers who provide high-purity raw materials, such as zinc oxide and boric acid, is crucial. The quality of these materials directly impacts the effectiveness of Zinc Borate in its end-use applications.

-

Supply Chain Management: Efficient supply chain management is essential to ensure timely delivery of raw materials, minimize lead times, and maintain optimal inventory levels. This involves establishing strong relationships with suppliers, implementing just-in-time (JIT) inventory practices, and leveraging technology for real-time tracking.

-

Cost Management: Securing competitive pricing for raw materials through bulk purchases, long-term contracts, and strategic sourcing can significantly reduce production costs. Additionally, exploring alternative suppliers can help mitigate risks associated with price fluctuations.

-

Quality Assurance: Ensuring the consistent quality of raw materials through rigorous testing and validation processes is essential to meet industry standards and regulatory requirements.

Understanding Zinc Borate

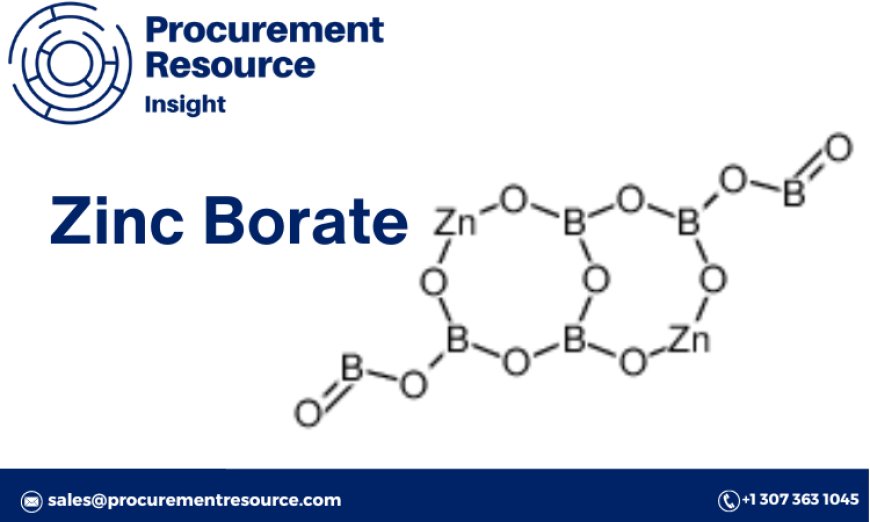

Zinc Borate is an inorganic compound with the chemical formula ZnB₂O₄(OH)₂. It is commonly used as a flame retardant in various materials, including plastics, rubber, and textiles. Additionally, Zinc Borate finds applications in ceramics, glass, and paints due to its excellent thermal stability and anti-corrosive properties.

Key Characteristics

-

Flame Retardant Properties: Zinc Borate acts as a flame retardant by releasing water and forming a protective layer of boron oxide, which inhibits the combustion process. It is often used in conjunction with other flame retardants, such as aluminum hydroxide and antimony trioxide, to enhance fire resistance.

-

Thermal Stability: Zinc Borate exhibits excellent thermal stability, making it suitable for use in high-temperature applications. It can withstand temperatures up to 600°C without decomposing, making it ideal for ceramics and glass production.

-

Anti-Corrosive Properties: Zinc Borate has anti-corrosive properties, which make it useful in protective coatings for metals. It helps prevent corrosion by forming a protective barrier that inhibits the reaction between the metal and the environment.

-

Environmental Impact: Zinc Borate is considered an environmentally friendly flame retardant due to its low toxicity and minimal impact on the environment. It is often used as a replacement for more harmful flame retardants, such as brominated compounds.

Market Drivers for Zinc Borate

Growing Demand for Flame Retardants

The increasing demand for flame retardants in industries such as construction, electronics, and textiles is a significant driver for the Zinc Borate market. As safety regulations become more stringent, manufacturers are turning to Zinc Borate as a safer and more effective alternative to traditional flame retardants.

Expanding Ceramics and Glass Industry

The ceramics and glass industry is another key market for Zinc Borate. Its thermal stability and anti-corrosive properties make it a valuable additive in the production of ceramics, glass, and enamels. The growing demand for these materials in construction and automotive applications is expected to drive the demand for Zinc Borate.

Environmental Regulations and Sustainability

Increasing environmental regulations and the push for sustainable products are driving the adoption of Zinc Borate in various industries. Its low toxicity and minimal environmental impact make it an attractive choice for manufacturers looking to comply with regulatory requirements and reduce their ecological footprint.

Technological Advancements

Advancements in production technologies and the development of new applications for Zinc Borate are also contributing to market growth. Innovations in flame retardant formulations, as well as the development of new uses in coatings and adhesives, are expanding the market potential for Zinc Borate.

Raw Materials Requirements for Zinc Borate Production

Key Raw Materials

-

Zinc Oxide (ZnO): Zinc oxide is one of the primary raw materials used in the production of Zinc Borate. It is a white powder with high thermal stability and is sourced from natural ores or produced synthetically.

-

Boric Acid (H₃BO₃): Boric acid is another essential raw material in Zinc Borate production. It is a weak acid derived from boron and is commonly used in various industrial applications, including glass manufacturing, ceramics, and flame retardants.

-

Water (H₂O): Water is used as a solvent and reaction medium in the production process. It facilitates the chemical reaction between zinc oxide and boric acid, resulting in the formation of Zinc Borate.

-

Catalysts and Additives: In some production processes, catalysts and additives may be used to enhance the reaction efficiency and improve the quality of the final product. These materials must be carefully selected to ensure they do not negatively impact the properties of Zinc Borate.

Quality Control and Compliance

Ensuring the quality of raw materials is critical in the production of Zinc Borate. Raw materials must meet stringent purity standards to ensure the effectiveness of the final product. Additionally, compliance with regulatory requirements, such as REACH and RoHS, is essential to ensure the safety and environmental sustainability of the product.

Costs and Key Process Information

Production Costs

The cost of producing Zinc Borate is influenced by several factors, including:

-

Raw Material Costs: The prices of zinc oxide and boric acid can fluctuate based on market conditions, availability, and supplier agreements. Effective sourcing strategies and bulk purchasing can help manage these costs.

-

Manufacturing Costs: Manufacturing costs include labor, energy, equipment maintenance, and facility overhead. Automation and process optimization can help reduce these costs by improving efficiency and reducing waste.

-

Quality Control and Testing: Ensuring the quality and safety of Zinc Borate requires investment in quality control testing, including purity analysis, thermal stability testing, and flame retardancy testing.

-

Regulatory Compliance Costs: Meeting regulatory requirements involves costs related to documentation, certifications, and inspections. Adhering to environmental and safety regulations is essential to avoid penalties and ensure market access.

-

Packaging and Distribution Costs: The cost of packaging materials and logistics also contributes to the overall production cost. Efficient packaging solutions and optimized distribution networks can help reduce these expenses.

Key Production Steps

-

Chemical Reaction: The production of Zinc Borate begins with the reaction of zinc oxide and boric acid in water. The reaction is typically carried out at elevated temperatures and under controlled conditions to ensure complete conversion of the raw materials.

-

Filtration and Washing: After the reaction, the Zinc Borate is separated from the reaction mixture through filtration. The solid product is then washed to remove any impurities or residual reactants.

-

Drying: The washed Zinc Borate is dried to remove any remaining moisture. This step is critical to ensure the stability and shelf life of the final product.

-

Milling and Sieving: The dried Zinc Borate is milled and sieved to achieve the desired particle size distribution. This step is important for ensuring consistent performance in its end-use applications.

-

Quality Control: The final product undergoes rigorous quality control testing to ensure it meets the required specifications for purity, particle size, thermal stability, and flame retardancy.

-

Packaging: The Zinc Borate is packaged in suitable containers to protect it from moisture and contamination. Proper packaging is essential for maintaining the quality and safety of the product during storage and transportation.

Looking for an Exhaustive and Personalized Report?

For businesses looking to optimize their Zinc Borate production process, an exhaustive and personalized report can provide valuable insights into procurement strategies, cost management, and key production details. By leveraging this comprehensive analysis, companies can make informed decisions, enhance production efficiency, and gain a competitive edge in the market.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Benking sley

Email: sales@procurementresource.com

Toll Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA