ZLD Plant Solutions for Sustainable Industrial Water Management

Water management has become one of the most critical challenges for industrial operations.

Water management has become one of the most critical challenges for industrial operations. Rapid industrial growth, limited freshwater availability, and tightening environmental regulations have forced industries to rethink how wastewater is handled. ZLD (Zero Liquid Discharge) plant solutions have emerged as an effective and sustainable approach to industrial wastewater treatment, enabling complete water reuse with zero liquid waste disposal.

What Is a ZLD Plant?

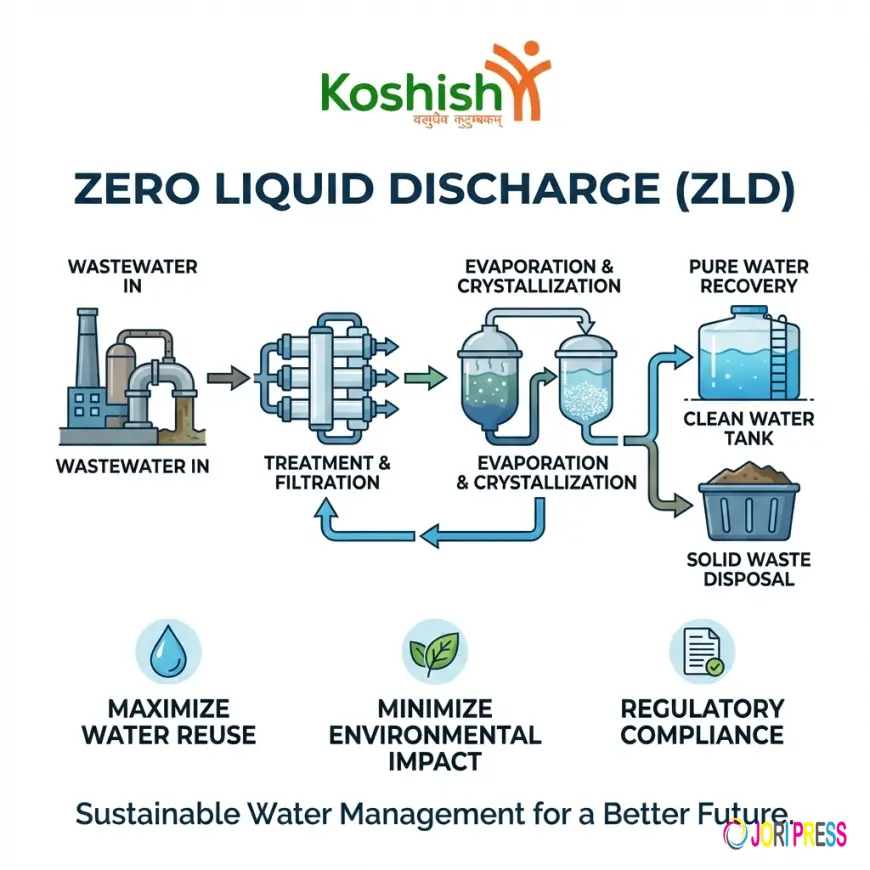

A ZLD plant is an advanced wastewater treatment system that treats industrial effluent in such a way that no liquid discharge is released into the environment. The system recovers usable water and converts dissolved contaminants into solid waste. This treated water is reused within the plant, while solid residues are safely disposed of or reused depending on their characteristics.

The main objective of a ZLD plant is to minimize water wastage, reduce environmental impact, and ensure regulatory compliance.

Need for ZLD Plants in Industries

Industries consume large volumes of water during manufacturing, cooling, cleaning, and processing. Discharging untreated or partially treated effluent can cause serious environmental damage. ZLD plants address this issue by enabling industries to operate with minimal freshwater intake and zero wastewater discharge.

ZLD systems are particularly important in regions facing water scarcity and strict pollution control requirements.

ZLD Plant Working Process

The operation of a ZLD plant involves multiple treatment stages designed to maximize water recovery.

Pre-Treatment and Equalization

Wastewater is first collected and passed through screening and equalization tanks. This step removes large solids and ensures consistent wastewater quality.

Chemical and Biological Treatment

Chemical dosing and biological processes reduce organic pollutants, suspended solids, and harmful compounds, preparing the water for advanced treatment.

Membrane Treatment

Reverse Osmosis membranes separate clean water from dissolved salts and impurities. The recovered water is reused in industrial processes.

Evaporation System

The RO reject water is sent to an evaporator, where water is separated from dissolved solids using thermal energy.

Crystallization

In the final stage, concentrated waste is converted into solid crystals, ensuring that no liquid effluent remains.

Applications of ZLD Plants

ZLD plants are widely used in industries that generate complex and high-strength wastewater, including:

-

Textile and dyeing units

-

Chemical and pharmaceutical industries

-

Power plants and energy sectors

-

Oil refineries and petrochemical units

-

Food and beverage processing industries

These industries rely on ZLD systems to meet environmental and operational requirements.

Benefits of ZLD Plant Installation

Installing a ZLD plant offers several advantages:

-

Complete reuse of treated wastewater

-

Zero discharge of liquid effluent

-

Reduced dependence on freshwater sources

-

Compliance with environmental regulations

-

Improved sustainability and corporate responsibility

ZLD plants also help industries prepare for future water-related challenges.

Challenges in ZLD Implementation

Despite its benefits, ZLD implementation requires careful planning. High capital cost, energy consumption, and skilled operation are common challenges. However, modern ZLD technologies focus on energy efficiency and optimized system design to reduce operating costs.

Selecting the right ZLD solution based on wastewater characteristics is essential for long-term performance.

Conclusion

ZLD plant solutions are transforming industrial wastewater management by enabling complete water reuse and eliminating liquid discharge. As environmental regulations become more stringent and water resources more limited, ZLD technology offers a reliable and sustainable solution for industries seeking long-term operational stability and environmental compliance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0